A kind of polymer composite film, its preparation method and application

A polymer film and composite film technology, which is applied in the field of polymer film materials and composite materials, can solve the problems of attenuation of film mechanical properties, large film specificity, poor UV shielding function of polymer films, etc., and achieve the rate of change in tensile strength Small, small amount of increase, excellent effect of UV shielding function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The present invention provides a method for preparing the above polymer composite film, which includes the following steps:

[0026] The dopamine solution is subjected to self-polymerization reaction on the surface of the polymer film to form a polydopamine layer with a thickness of ≥100 nm to obtain the polymer composite film.

[0027] Specifically, the polymer film is immersed in the prepared dopamine solution, and the dopamine self-polymerizes on the surface of the polymer film to form a polydopamine layer. When the thickness is not less than 100 nm, the resulting composite film is the polymer composite film.

[0028] The dopamine solution is a mixed solution of dopamine and a buffer. In the dopamine solution, the concentration of dopamine is 1 mg / mL-10 mg / mL, preferably 1 mg / mL-5 mg / mL.

[0029] The present invention has no particular limitation on the above-mentioned buffer, as long as the buffer is well known to those skilled in the art, it is used to adjust the pH of the...

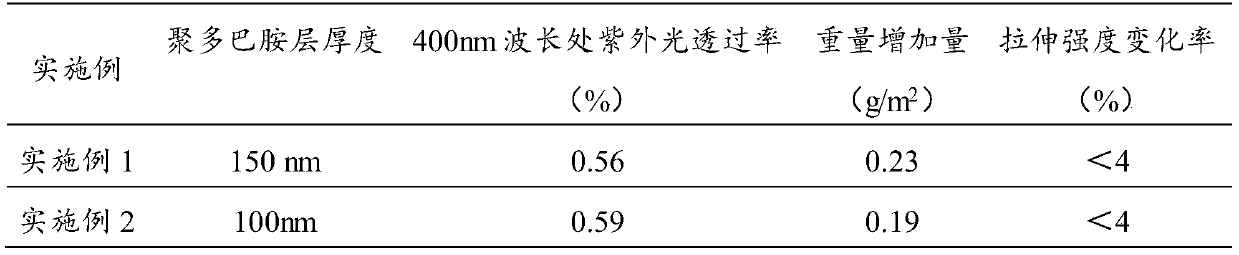

Embodiment 1

[0038] The polyvinylidene fluoride film was immersed in a mixed solution of dopamine and Tris-HCl buffer to react, and the concentration of dopamine was controlled to 2mg / mL, the pH of the mixed solution was 8.5, and the reaction temperature was 30°C. After the polydopamine layer was formed, The obtained composite film is dried in an oven in an air atmosphere at a temperature of 80°C and a drying time of 10 minutes to obtain a polymer composite film. The thickness of the final formed polydopamine layer is measured by the ellipsometer It is 150nm.

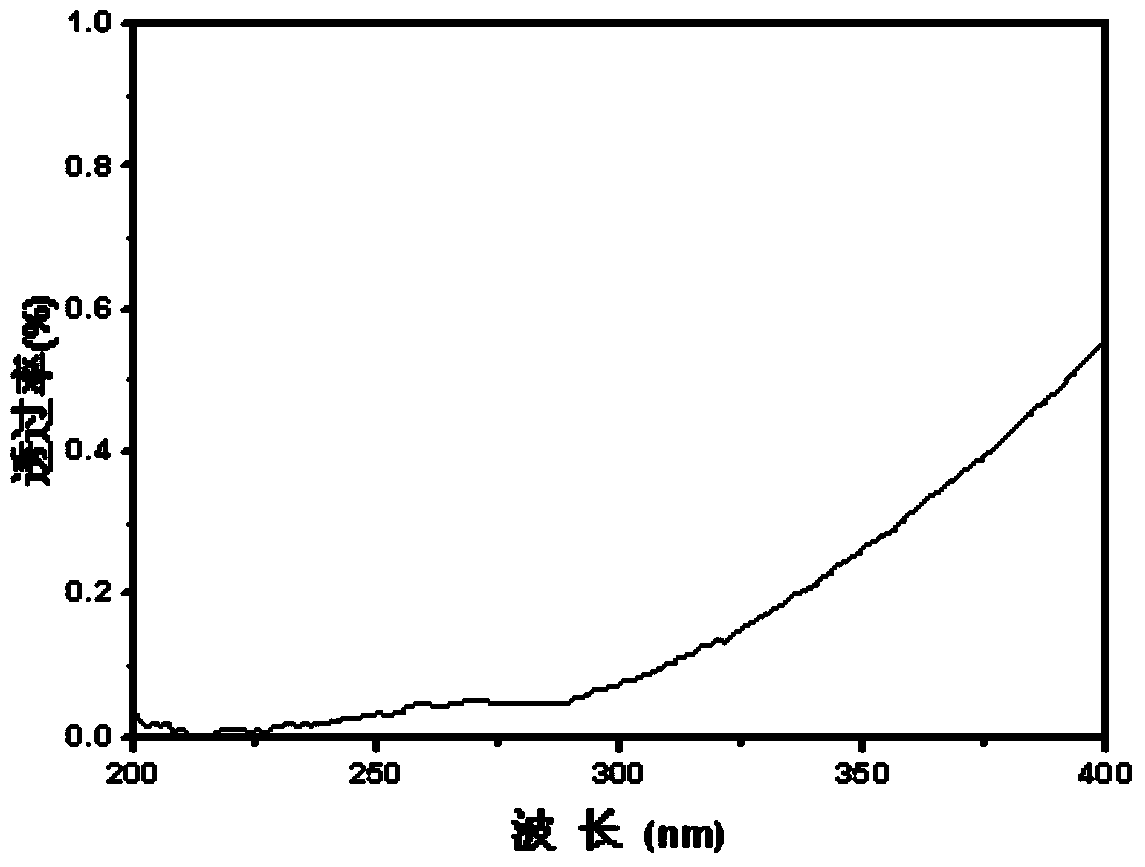

[0039] After obtaining the polymer composite film, use an ultraviolet spectrophotometer to detect the ultraviolet transmittance of the polymer composite film, see figure 1 . The results show that at the wavelength of 200nm-400nm, with the increase of the wavelength, the overall ultraviolet light transmittance shows an upward trend. The ultraviolet light transmittance at 250nm is obviously less than 0.1%, and reaches the maximum value o...

Embodiment 2

[0042] The polyvinylidene fluoride film was immersed in a mixed solution of dopamine and Tris-HCl buffer to react, and the concentration of dopamine was controlled to be 3 mg / mL, the pH of the mixed solution was 8.5, and the reaction temperature was 35°C. After the polydopamine layer was formed, The obtained composite film is dried in an oven in an air atmosphere at a temperature of 80°C and a drying time of 10 minutes to obtain a polymer composite film. The thickness of the final formed polydopamine layer is measured by the ellipsometer It is 100nm.

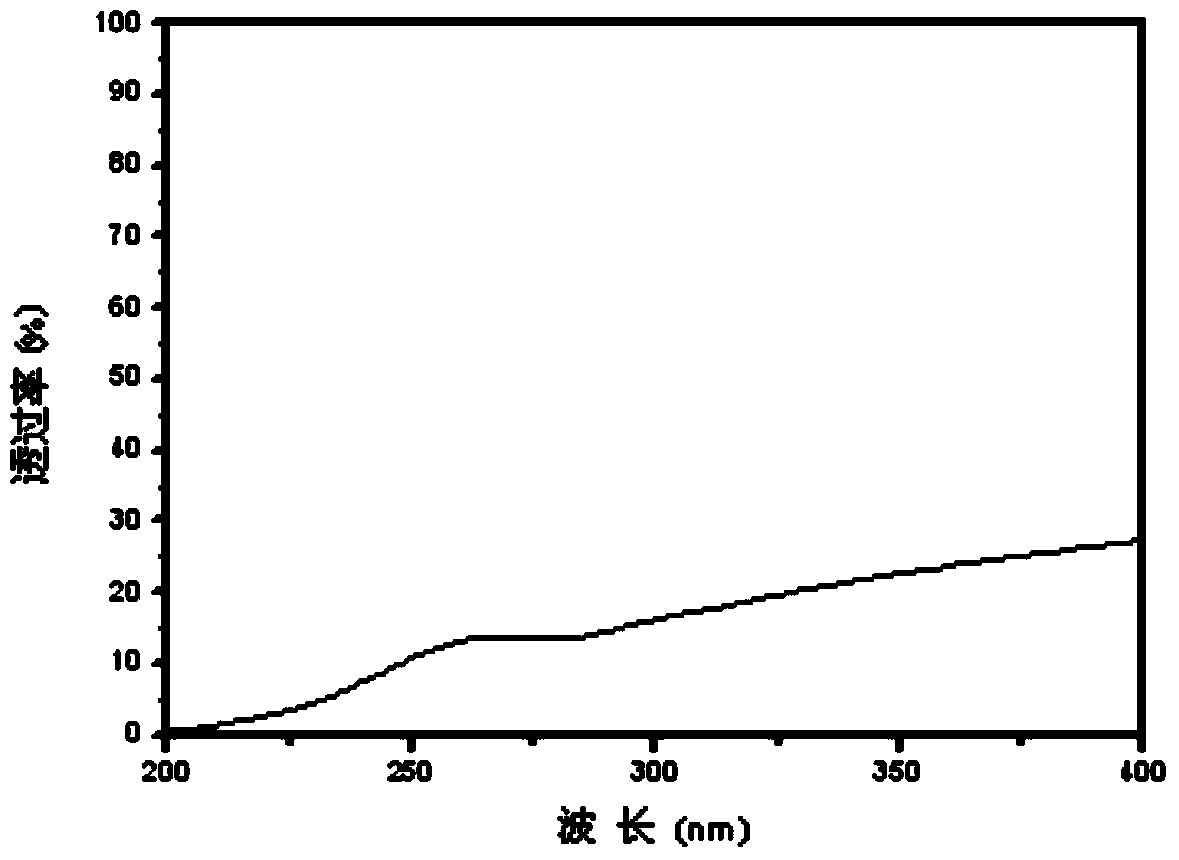

[0043] After the polymer composite film is obtained, the ultraviolet transmittance of the polymer composite film is detected by an ultraviolet spectrophotometer. The results show that at a wavelength of 200nm to 400nm, as the wavelength increases, the overall ultraviolet transmittance is An upward trend, reaching a maximum of 0.56% at 400nm.

[0044] At the same time, the weight increase and tensile strength change rate of the polym...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com