Emulsion pump without speed reducer

A technology of emulsion pump and reducer, which is applied in the direction of pump components, pump control, machine/engine, etc., can solve the problems of complex structure and low transmission efficiency, and achieve the effect of high transmission efficiency, simple and compact structure, and large starting torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings. However, it should be understood that the accompanying drawings are provided only for better understanding of the present invention, and they should not be construed as limiting the present invention.

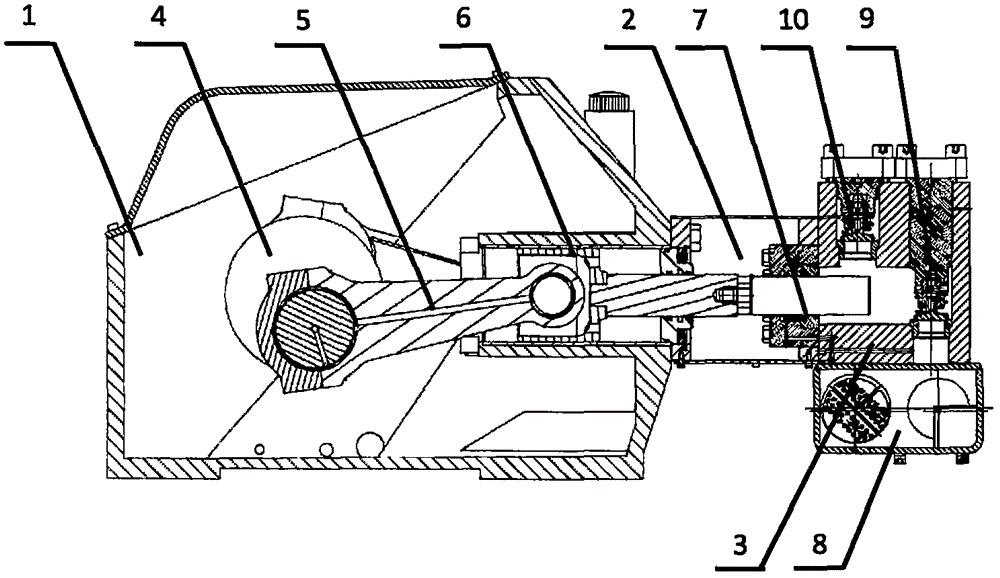

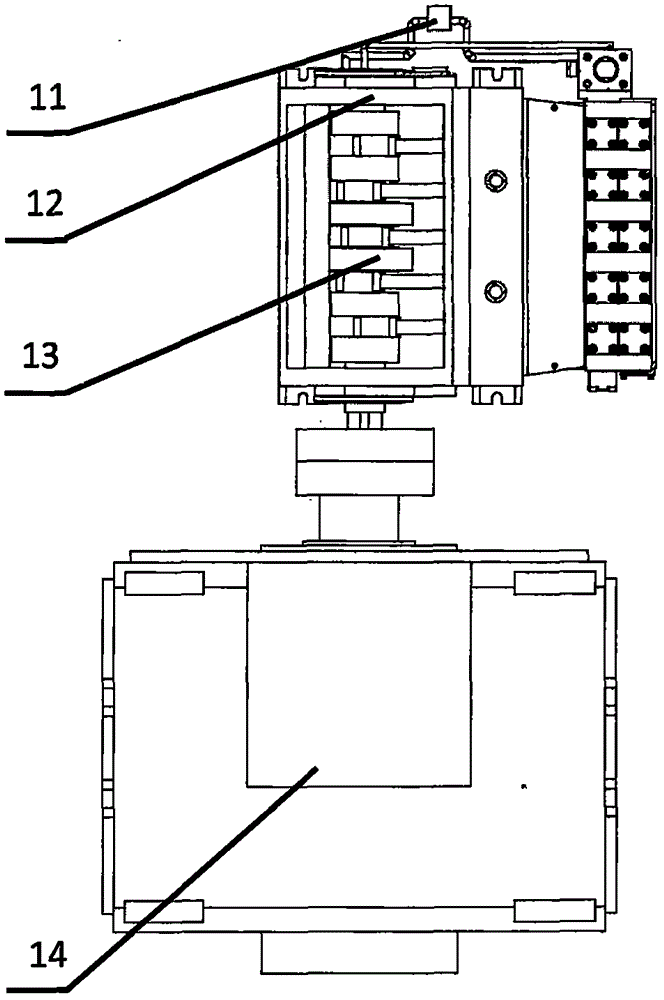

[0016] See attached figure 1 And attached figure 2 , which describes a preferred embodiment of the deceleratorless emulsion pump according to the present invention, which has a gearless mechanical drive structure based on a permanent magnet direct drive motor.

[0017] The emulsion pump without reducer includes crankcase 1, middle case 2, pump head 3 and other components. The permanent magnet direct drive motor 14 drives the crankshaft 4 in the crankcase 1 to rotate through the low-speed heavy-duty coupling, and the crankshaft 4 drives the connecting rod 5, the slider 6 and the plunger 7, and converts the rotational motion of the crankshaft 4 into the motion of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com