Device and method for treating spraying waste gas jointly through hot corona discharge and high-temperature pyrolysis

A high-temperature pyrolysis and combined treatment technology, which is applied in the direction of combined devices, gas treatment, separation methods, etc., can solve the problems of insufficient energy density per unit volume of discharge space, unsuitability for processing high-concentration organic gases, and regeneration of adsorbents, etc., to avoid Generation of secondary pollutants, simple and convenient operation, low investment and treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

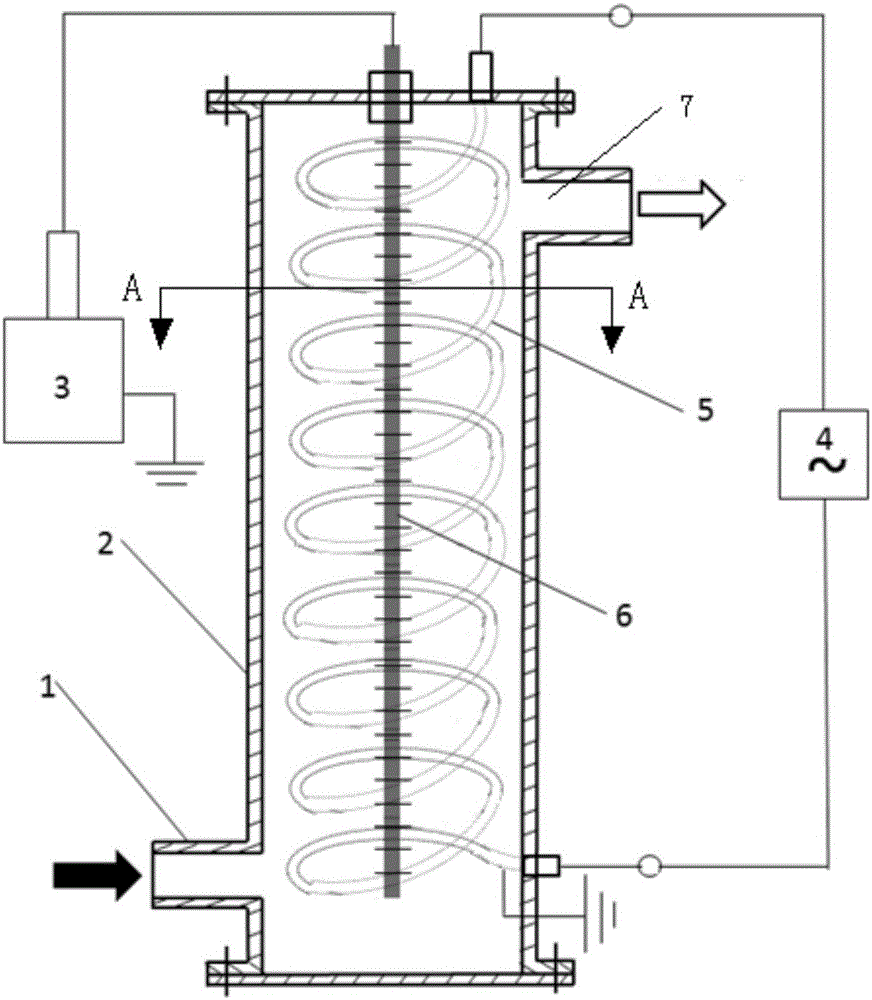

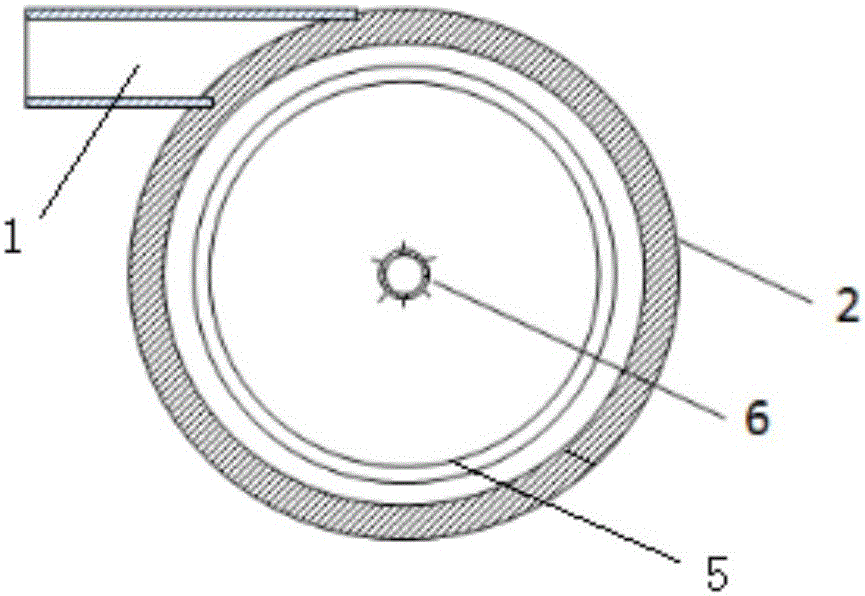

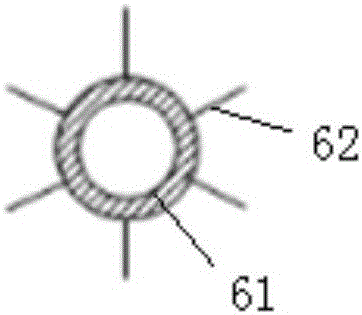

[0038] Such as Figure 1~3 As shown, the device for thermal corona discharge and pyrolysis combined treatment of spraying waste gas in this embodiment includes: tangential swirl inlet 1, reaction cylinder 2, high voltage DC power supply 3, temperature controller 4, spiral electric heating tube electrode 5, discharge Electrode tube 6 and tangential swirl outlet 7.

[0039] In this embodiment, the tangential swirl inlet 1 is located at the lower end of the reaction cylinder 2. Its cross section is rectangular with a length-to-width ratio of 3:4. The cross-sectional area is designed according to the average wind speed range of the airflow of 8-15m / s.

[0040] In this embodiment, the reaction cylinder 2 is composed of a cylinder, an upper and lower cover, and a gas inlet and outlet. The diameter of the cylinder is determined by the gas volume and discharge voltage for processing VOCs. The upper and lower covers are made of polytetrafluoroethylene. But not limited to this material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com