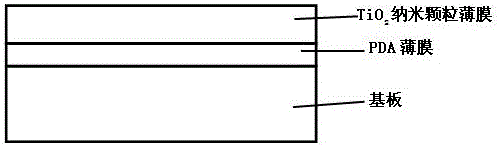

Polydopamine/titanium dioxide double-layer composite film and preparation method thereof

A polydopamine film, titanium dioxide technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc., can solve the problem of uneven film thickness, limited application, and particles that cannot be exposed and other problems, to achieve the effect of improving hydrophilicity, good biocompatibility, and improving binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Add 0.08mg of dopamine hydrochloride into 40ml of deionized water, stir until completely dissolved, and obtain A solution;

[0018] (2) Take out 5ml of A solution, put TiO 2 The hydrosol and the A solution are mixed at a volume ratio of 1:1, and fully stirred and mixed evenly to obtain the B solution;

[0019] (3) Add the clean PS substrate to the remaining A solution, take it out after soaking for 10 hours, and dry it at 50°C to obtain a PDA film on the PS substrate;

[0020] (4) Add 20ul B solution dropwise on the PDA film in step 3), spin-coat at 6000r / min for 30s, and dry at 50°C for 10h to obtain PDA / TiO 2 Double layer composite film.

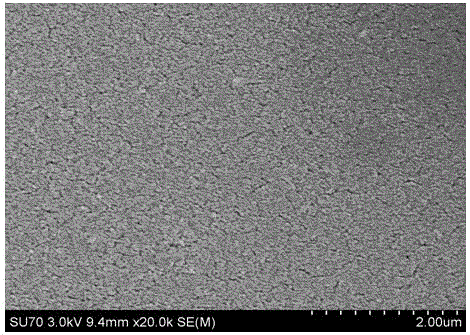

[0021] The surface morphology of the composite film prepared in this example is shown in figure 2 , TiO in thin films 2 The nanoparticles are uniformly dispersed, and after 20 minutes of UV365 irradiation, the contact angle of the titanium dioxide particle film on the surface is changed from 35 。 down to 5 。 . The double...

Embodiment 2

[0023] (1) Add 0.09mg of dopamine hydrochloride into 50ml of deionized water, stir until completely dissolved, and obtain A solution;

[0024] (2) Take out 6ml of A solution, put TiO 2 The hydrosol and the A solution are mixed at a volume ratio of 1:3, and fully stirred and mixed evenly to obtain the B solution;

[0025] (3) Add the clean PP substrate to the remaining A solution, take it out after soaking for 10 hours, and dry it at 52°C to obtain a PDA film on the PP substrate;

[0026] (4) Add 22ul B solution dropwise on the PDA film in step 3), spin-coat at 6000r / min for 32s, and dry at 52°C for 10h to obtain PDA / TiO 2 Double layer composite film.

[0027] After the composite film prepared in this example was irradiated with UV365 for 20 minutes, the contact angle of the titanium dioxide particle film on its surface was changed from 45 to 45 。 down to 10 。 . The double-layer composite film is firmly combined with the PP substrate, and the titanium dioxide particle film...

Embodiment 3

[0029] (1) Add 0.10mg of dopamine hydrochloride into 60ml of deionized water, stir until completely dissolved, and obtain A solution;

[0030] (2) Take out 7ml of A solution, put TiO 2 Mix the hydrosol and the A solution at a volume ratio of 1:5, and stir and mix well to obtain the B solution;

[0031] (3) Add the clean quartz substrate to the remaining solution A, soak it for 11 hours, take it out, and dry it at 54°C to obtain a PDA film on the quartz substrate;

[0032] (4) Add 24ul B solution dropwise on the PDA film in step 3, spin-coat at 7000r / min for 34s, and dry at 54°C for 11h to prepare PDA / TiO with high bonding strength 2 Double layer composite film.

[0033] After the composite film prepared in this example was irradiated with UV365 for 20 minutes, the contact angle of the titanium dioxide particle film on its surface was changed from 55 to 55 。 reduced to 20 。 . The double-layer composite film is firmly combined with the quartz substrate, and the titanium dio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com