On-line spreading rate and uniformity detecting device and method for reconstituted tobacco

A technology of reconstituted tobacco leaves and detection device, which is applied in the direction of measuring device, weighing by removing certain components, material analysis by optical means, etc. Online detection of production needs and other issues, to achieve the effect of easy timely adjustment and control, mature technology, and fast detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

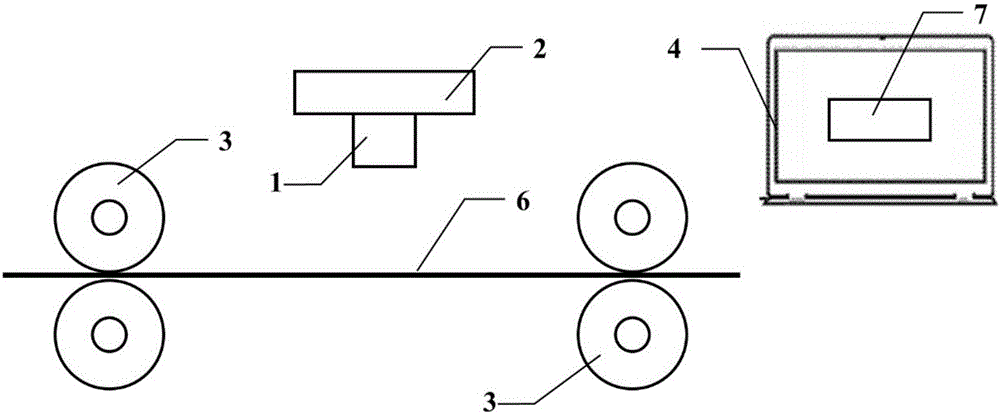

[0057] Such as figure 1 As shown, a reconstituted tobacco leaf coating rate and its uniformity online detection device, the device includes a near-infrared moisture meter detection module 1, a mechanical motion scanning device 2, a reconstituted tobacco sheet conveying device 3, a main control center 4 and a signal transceiver device 5;

[0058] The near-infrared moisture meter detection module 1 detects the measured reconstituted tobacco leaves 6 entering the detection area in real time, detects the moisture content and grammage information of the measured reconstituted tobacco leaves 6, and outputs corresponding information to the control center 4. The detection data, the detection data includes the moisture content and grammage data of the tested reconstituted tobacco leaf 6;

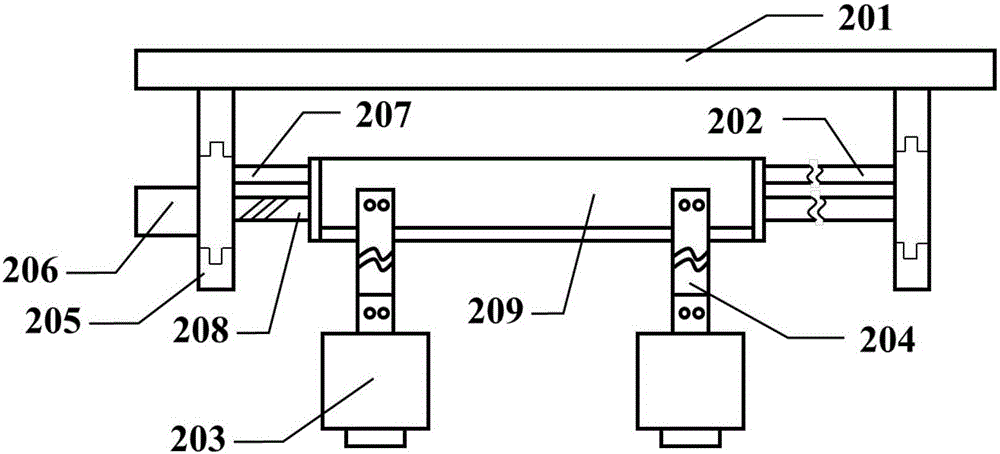

[0059] The near-infrared moisture meter detection module 1 is installed on the mechanical motion scanning device 2, controlled by the main control center 4, and moves back and forth on the guide rai...

Embodiment

[0067] Embodiment: In the field of process quality control of reconstituted tobacco leaf products by papermaking method at present, the uniformity of coating and the stability control of coating liquid play an important role in the quality of reconstituted tobacco leaf products, and the detection of coating rate and coating uniformity is proposed. Very high requirements; therefore, with a width of 0.8m reconstituted tobacco leaf sheet as the measured object, the reconstituted tobacco leaf coating rate and uniformity online detection device and method thereof of the present invention are used for detection;

[0068] The near-infrared moisture meter detection module 1 includes two near-infrared moisture meters with identical specifications and parameters; the measurement range of the near-infrared moisture meter detection module is 1 to 30%, and the measurement accuracy is controlled to be 2σ≤±0.15 %, (wherein, σ represents the standard deviation), the drift of this near-infrared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com