Lithium-ion power battery and preparation method thereof

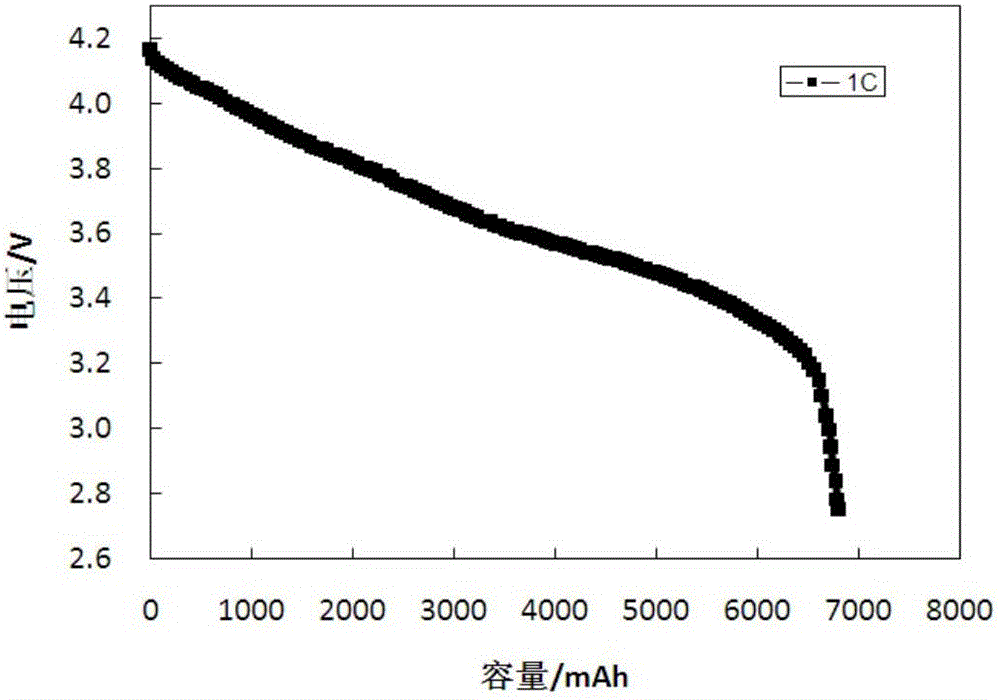

A power battery, lithium ion technology, applied in the field of lithium ion power battery and its preparation, can solve the problems of poor safety of ternary lithium battery, low battery energy density, etc., and achieve improved safety, long service life and large battery capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The preparation method of the lithium-ion power battery of high energy density in the present embodiment comprises the following steps:

[0049] (1) Raw material pretreatment

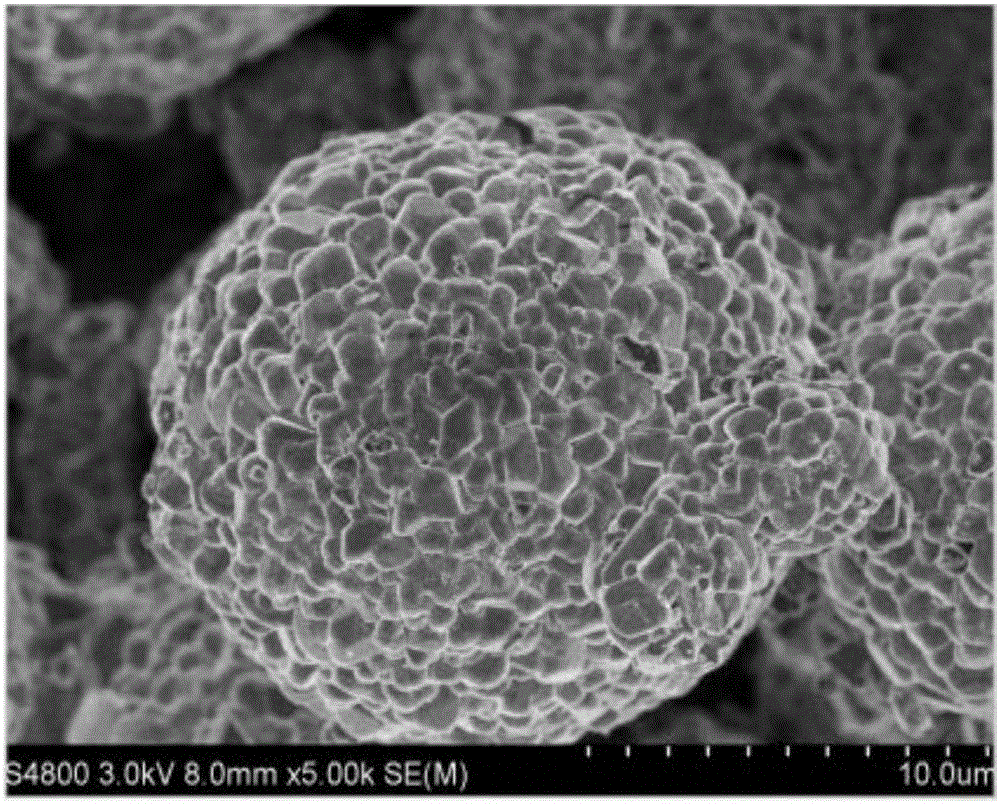

[0050] The positive electrode active material LiNi 0.8 co 0.15 Al 0.05 o 2 (NCA), conductive agent 1 (Supper-P), conductive agent 2 (KS-6), binder (PVDF) and auxiliary agent (oxalic acid) were dried under vacuum at 120°C for 4h.

[0051] (2) Raw material mixing

[0052] Add the dried PVDF into nitrogen-methylpyrrolidone and fully dissolve it at 25°C. In an environment with a relative humidity of 20%, add the positive electrode active material (93.0wt%), conductive agent 1 (2.5wt%), conductive agent 2 (1.0wt%) and auxiliary agent (0.5wt%) into the above-mentioned dissolved PVDF (3.0wt%) nitrogen-methylpyrrolidone, stirred for 6 h, and nitrogen protection was used during the stirring process.

Embodiment 2

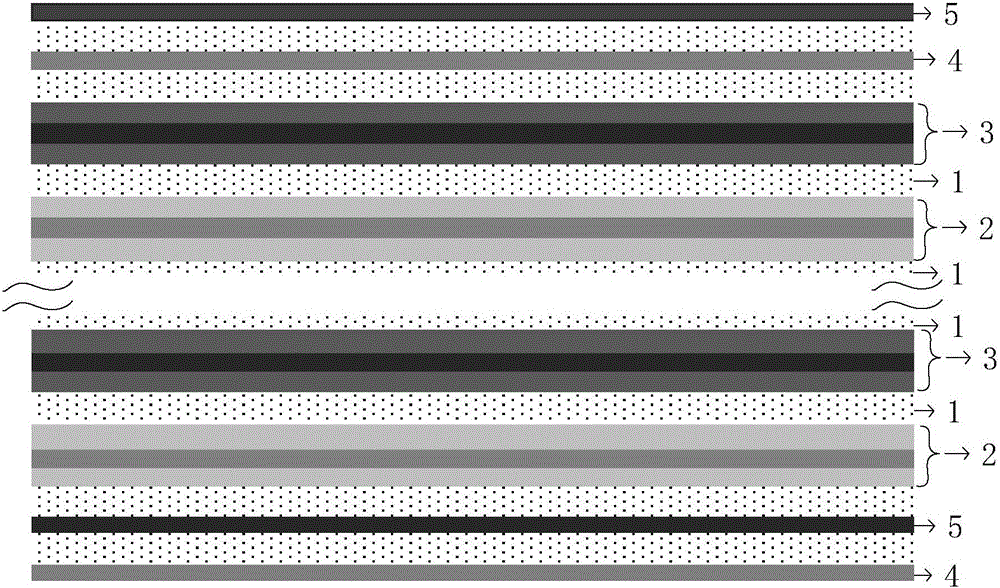

[0063] A high-energy-density lithium-ion power battery includes a battery cell, an electrolyte, and an aluminum-plastic case, wherein the battery cell is completed by stacking a positive pole piece, a negative pole piece, and a diaphragm. The preparation method of the lithium-ion power battery of high energy density in the present embodiment comprises the following steps:

[0064] (1) Raw material pretreatment

[0065] The positive electrode active material LiNi 0.8 co 0.15 Al 0.05 o 2 (NCA), conductive agent 1 (Supper-P), conductive agent 2 (graphite carbon), binder (PVDF) and auxiliary agent (oxalic acid) were dried under vacuum at 120 °C for 6 h.

[0066] (2) Raw material mixing

[0067] Add the dried PVDF into nitrogen-methylpyrrolidone and fully dissolve it at 25°C. In an environment with a relative humidity of 20%, add the positive electrode active material (94.0wt%), conductive agent 1 (1.5wt%), conductive agent 2 (0.5wt%) and auxiliary agent (0.8wt%) into the abo...

Embodiment 3

[0078] A high-energy-density lithium-ion power battery includes a battery cell, an electrolyte, and an aluminum-plastic case, wherein the battery cell is completed by stacking a positive pole piece, a negative pole piece, and a diaphragm. The preparation method of the lithium-ion power battery of high energy density in the present embodiment comprises the following steps:

[0079] (1) Raw material pretreatment

[0080] The positive electrode active material LiNi 0.8 co 0.15 Al 0.05 o 2 (NCA), conductive agent 1 (Supper-P), conductive agent 2 (graphite carbon), binder (PVDF) and auxiliary agent (maleic acid) were dried under vacuum at 120 °C for 4 h.

[0081] (2) Raw material mixing

[0082] Add the dried PVDF into nitrogen-methylpyrrolidone and fully dissolve it at 25°C. In an environment with a relative humidity of 20%, add the positive electrode active material (92.0wt%), conductive agent 1 (3.5wt%), conductive agent 2 (0.5wt%) and auxiliary agent (0.8wt%) into the abo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com