Method for producing gel detergent

A manufacturing method and cleaning agent technology, which are applied in the preparation of detergent mixture compositions, chemical instruments and methods, detergent compositions, etc., can solve the problem of time-consuming cleaning, no disclosure of cylindrical containers, and easy gelling agents. Problems such as mildew and deterioration, to achieve the effect of reducing the number of working hours and high production performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0188] (1) Purified water 67.9%

[0189] (2) Glycerin 10.0%

[0190] (3) Dipropylene glycol 7.0%

[0191] (4) 1,2-Hexanediol 2.5%

[0192] (5) Xyloglucan (registered trademark: GLYLOID 6C, / DSP GOKYO Food Chemical Co., Ltd.) 0.8% 0.8%

[0193] (6) Xanthan gum 0.2%

[0194] (7) Lauric acid 5.9%

[0195] (8) Myristic acid 2.2%

[0196] (9) Palmitic Acid 1.0%

[0197] (10) Stearic acid 0.4%

[0198] (11) Oleic acid 0.6%

[0199] (12) Sodium hydroxide 1.5%

[0200] Total 100.0%

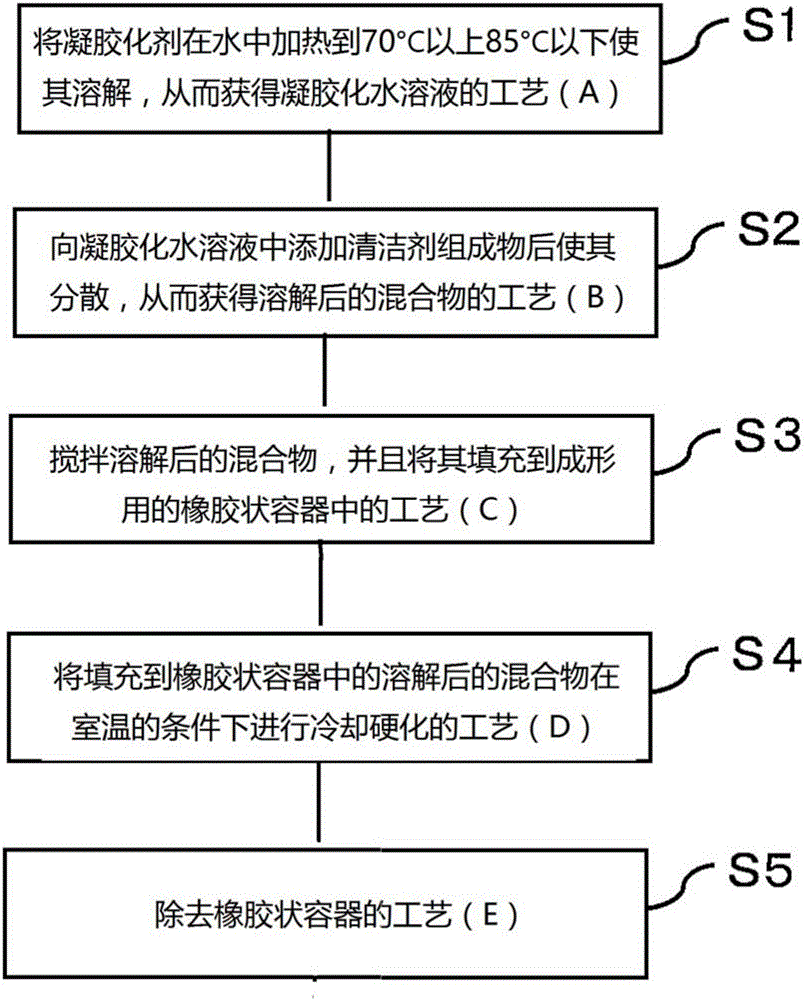

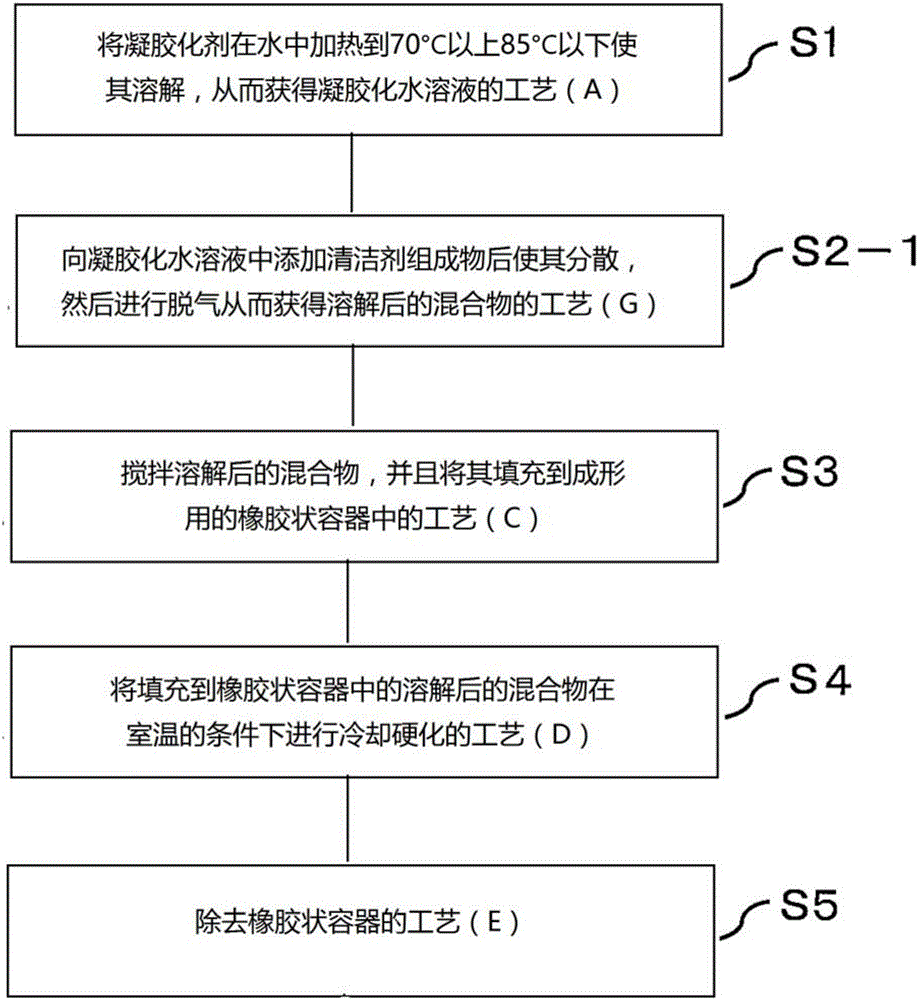

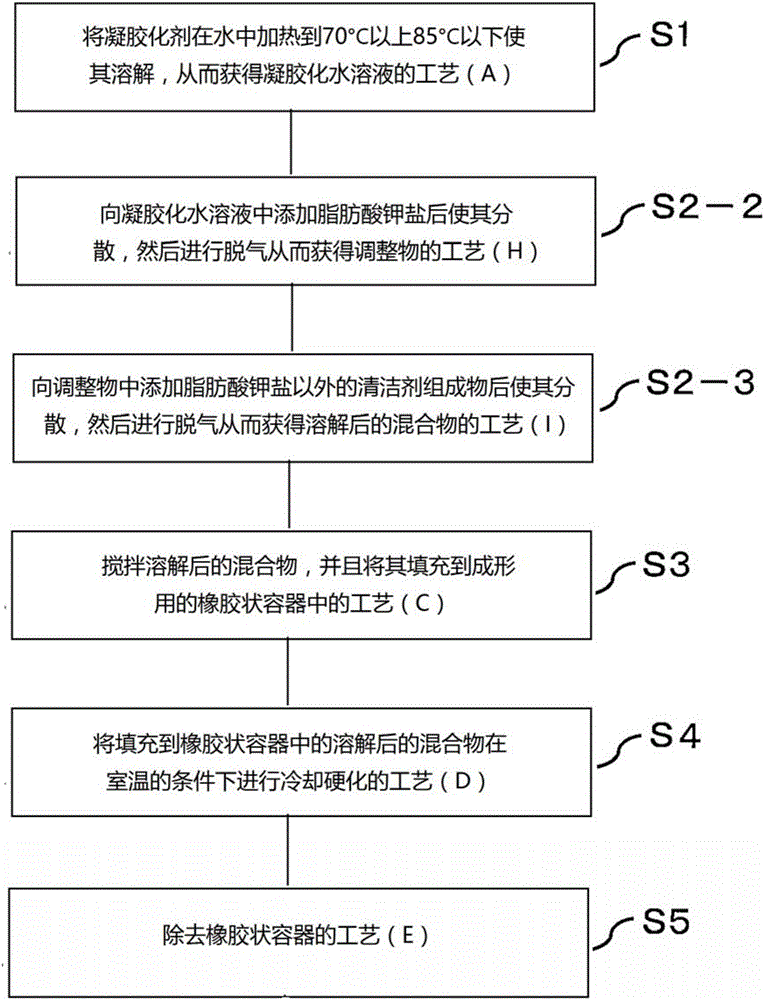

[0201] method

[0202] Wet ingredients (5), (6) in the mixture of ingredients (2), (3) and disperse them, then add them to ingredient (1), heat to 85°C, and stir to dissolve them (step S1). Then, components (7) to (12) are added thereto, mixed, dissolved, and stirred to obtain a uniform dissolved mixture (step S2). Then, the dissolved mixture is kept at 65° C. to 80° C., the dissolved mixture is stirred, and filled into a rubber container for molding (step S3), and then the dissolved mixture...

Embodiment 2

[0204] (1) Purified water 48.4%

[0205] (2) Sorbitol 10.0%

[0206] (3) Propylene Glycol 10.0%

[0207] (4) 1,2-Hexanediol 2.5%

[0208] (5) Xyloglucan (registered trademark: GLYLOID 6C) 1.0%

[0209] (6) Xanthan gum 0.5%

[0210] (7) Lauric acid 5.9%

[0211] (8) Myristic acid 2.2%

[0212] (9) Palmitic Acid 1.0%

[0213] (10) Stearic acid 0.3%

[0214] (11) Oleic acid 0.6%

[0215] (12) Potassium hydroxide 2.60%

[0216] (13) Lauryl amidopropyl hydroxysulfobetaine (SOFTAZOLINE LSB / / Chuanyan Fine Chemical Co., Ltd.) 15.0%

[0217] Total 100.0%

[0218] method

[0219] Wet and disperse ingredients (5) and (6) in the mixture of ingredients (2) to (4), then add them to ingredient (1), heat to 85°C, and stir to dissolve them (step S1). Then, components (7) to (12) are added thereto and mixed, heated to 75° C. to 85° C. to dissolve, and then component (13) is added and stirred to obtain a uniformly dissolved mixture (step S2). Then, the dissolved mixture is kept at 75...

Embodiment 3

[0221] (1) Purified water 48.0%

[0222] (2) Dipropylene glycol 7.0%

[0223] (3) 1,2-Hexanediol 2.5%

[0224] (4) Xanthan Gum 0.5%

[0225] (5) Carrageenan 2.0%

[0226] (6) Aqueous solution of coconut oil fatty acid amidopropyl betaine (OBAZORIN CAB30 / Toho Chemical Industry Co., Ltd.) 40.0%

[0227] Total 100.0%

[0228] method

[0229] Wet ingredients (4), (5) in the mixture of ingredients (2), (3) and disperse them, then add them to ingredient (1), heat to 85°C, and stir to dissolve them (step S1). Then, the ingredient (6) is added thereto, mixed, and stirred to obtain a uniformly mixed dissolved mixture (step S2). Then, the dissolved mixture is kept at 68° C. to 80° C., the dissolved mixture is stirred, and filled into a rubber container for molding (step S3), and then the dissolved mixture filled in the rubber container is The mixture was allowed to stand at room temperature (step S4), and then the rubbery container was removed with a toothpick (step S5), thereby...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com