Nano silicon dioxide grafted organic functional polymer macrolide insecticide slow-release agent and preparation method thereof

A nano-silicon dioxide and macrolide technology, which is applied in the field of new pesticide formulations, can solve the problems of difficulty in exerting drug efficacy, poor dispersibility, and lack of controllable release ability of active ingredients, so as to reduce the number of application times, Low cost and the effect of improving the utilization rate of pesticides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

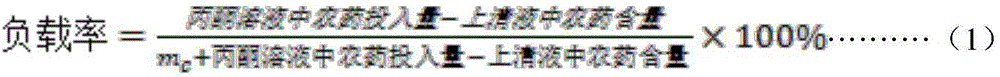

[0039] (1) Add 1.0g nano-calcium carbonate, 0.5g cetyltrimethylammonium bromide (CTAB) and 104mL ethanol to a 250mL flask, add 13mL 27wt% ammonia water after ultrasonic dispersion for half an hour, start stirring, and control the reaction temperature in a water bath At 50°C, add 0.02mol ethyl orthosilicate to the above reaction system, and react for 72h;

[0040] (2) adding excessive dilute hydrochloric acid, removing the nano-calcium carbonate template, centrifuging to remove the supernatant and washing the obtained solid, repeating three times, to obtain hollow nano-silica A;

[0041] (3) Add 100mL of water and ethanol (V / V=1:1) and A obtained in step (2) to the three-necked flask, ultrasonically disperse for half an hour and control the reaction temperature at 70°C, add dropwise 0.01mol (CH 3 CH 2 O) 2 CH 3 Si(CH 2 ) 3 NH 2 , reacted for 2 hours, centrifuged to remove the supernatant and washed the obtained solid, and repeated three times to obtain amino-modified holl...

Embodiment 2

[0049] (1) Add 1.5g nano-calcium carbonate, 2.0g cetyltrimethylammonium bromide (CTAB) and 99mL ethanol to a 250mL flask, add 16.5mL 27wt% ammonia water after ultrasonic dispersion for half an hour, start stirring, and control the reaction in a water bath At a temperature of 40°C, add 0.02mol ethyl orthosilicate to the above reaction system, and react for 36 hours;

[0050] (2) adding excessive dilute hydrochloric acid, removing the nano-calcium carbonate template, centrifuging to remove the supernatant and washing the obtained solid, repeating three times, to obtain hollow nano-silica A;

[0051] (3) Add 100mL of water and ethanol (V / V=1:1), A obtained in step (2) to the three-necked flask, ultrasonically disperse for half an hour and control the reaction temperature at 40°C, add dropwise 0.04mol (CH 3 O) 3 Si(CH 2 ) 3 NH 2 , reacted for 2 hours, centrifuged to remove the supernatant and washed the obtained solid, and repeated three times to obtain amino-modified hollow n...

Embodiment 3

[0057] (1) Add 1.5g nano-calcium carbonate, 0.05g cetyltrimethylammonium bromide (CTAB) and 94mL ethanol to a 250mL flask, add 23.5mL 27wt% ammonia water after ultrasonic dispersion for half an hour, start stirring, and control the reaction in a water bath At a temperature of 25°C, add 0.02mol ethyl orthosilicate to the above reaction system, and react for 72 hours;

[0058] (2) adding excessive dilute hydrochloric acid, removing the nano-calcium carbonate template, centrifuging to remove the supernatant and washing the obtained solid, repeating three times, to obtain hollow nano-silica A;

[0059] (3) Add 100mL of water and ethanol (V / V=1:1), A obtained in step (2) to the three-necked flask, ultrasonically disperse for half an hour and control the reaction temperature at 50°C, add dropwise 0.03mol (CH 3 CH 2 O) 2 CH 3 Si(CH 2 ) 3 NH 2 , reacted for 2 hours, centrifuged to remove the supernatant and washed the obtained solid, and repeated three times to obtain amino-modi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com