Anti-oxidative sheep feed

A sheep feed and antioxidant technology, applied in the direction of animal feed, animal feed, additional food elements, etc., can solve the problems of lowering the quality of mutton, affecting the growth of sheep, and reducing the resistance of sheep.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

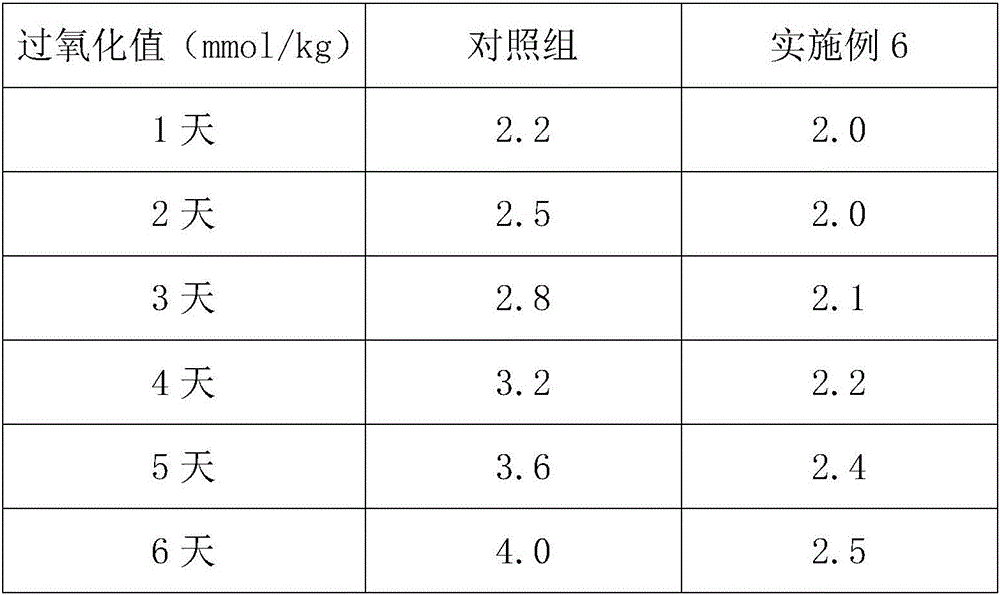

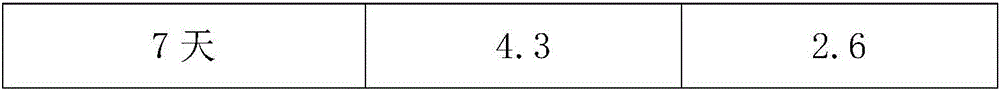

Examples

Embodiment 1

[0021] An antioxidant sheep feed, its raw materials include: corn flour, rapeseed meal, soybean flour, sodium chloride, fermented red wine lees, oat flour, mangosteen peel extract, honey, silage mulberry leaves, yeast selenium, silage tomato Skin dregs, silage alfalfa grass powder, silage corn stalks, sweet potato vines, gourd seedlings, sheep premix, sodium bicarbonate.

Embodiment 2

[0023] An anti-oxidation sheep feed, its raw materials include by weight: 15 parts of corn flour, 15 parts of rapeseed meal, 15 parts of soybean meal, 5 parts of sodium chloride, 15 parts of fermented red wine lees, 15 parts of oat flour, mangosteen 3 parts of fruit peel extract, 4 parts of honey, 10 parts of silage mulberry leaves, 0.5 parts of yeast selenium, 1 part of silage tomato skin residue, 35 parts of silage alfalfa powder, 20 parts of silage corn stalks, 15 parts of sweet potato vines, 10 parts of gourd seedlings , 2.5 parts of sheep premix, 0.3 parts of sodium bicarbonate.

Embodiment 3

[0025] An anti-oxidation sheep feed, its raw materials include by weight: 25 parts of corn flour, 10 parts of rapeseed meal, 20 parts of soybean meal, 3 parts of sodium chloride, 20 parts of fermented red wine lees, 10 parts of oat flour, mangosteen 5 parts of fruit peel extract, 2 parts of honey, 12 parts of mulberry leaves in silage, 0.3 parts of yeast selenium, 2 parts of silage tomato skin residue, 25 parts of silage alfalfa grass powder, 25 parts of silage corn stalks, 10 parts of sweet potato vines, 15 parts of gourd seedlings , 1.5 parts of sheep premix, 0.5 parts of sodium bicarbonate;

[0026] Among them, in the preparation process of fermented red wine grains, mix red wine grains powder, corn flour, bean cake powder, ammonium sulfate, and water, adjust pH=5.4 with calcium hydroxide aqueous solution, heat up to 125°C, and autoclave for 20 minutes , cooled to room temperature, inoculated with yeast liquid, heated to 35°C, kept warm for 4 days, and dried to obtain ferme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com