Preparation method of cellulose-based core-shell CdS/ZnO (cadmium-sulfur/zinc oxide) photocatalyst

A core-shell structure, cellulose-based technology, applied in the field of preparation of cellulose-based core-shell structure CdS/ZnO photocatalytic materials, can solve the problems of difficult industrialization, complicated process, high production cost, etc., to achieve broadened spectral response range, The effect of prolonging the exciton decay time and the precise and controllable synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

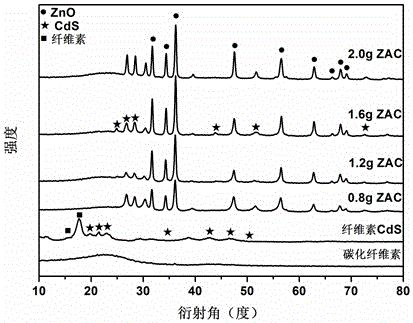

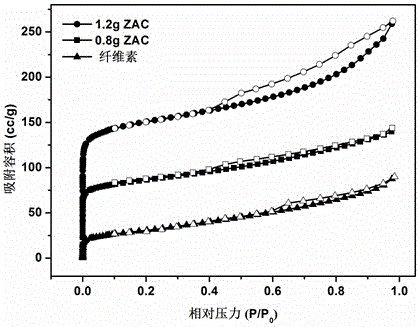

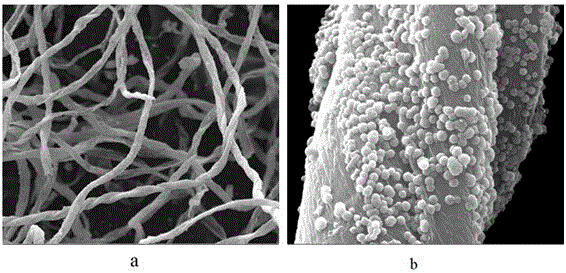

[0027] Weigh 2.66 g of cadmium acetate and mix it with distilled water, stir until completely dissolved, then take 2 g of cotton washed and dried with absolute ethanol and immerse it in the cadmium acetate solution for 2 hours, so that the cotton is soaked in the solution, and then put in Dry in a constant temperature drying oven at 40°C for 2 hours; then weigh 4.80 g of sodium sulfide and mix it with distilled water, and stir until it is completely dissolved; add the above-mentioned dried cotton and prepared sodium sulfide solution into the hydrothermal reaction kettle, tighten the Put the reaction kettle into a constant temperature drying oven, the reaction temperature is 100 °C, and react for 14 hours; after the reaction is completed, take it out and filter it with a Buchner funnel, wash the filter residue with distilled water and absolute ethanol for 3 times, and then put it in a constant temperature drying box at 20 °C After drying for 3 hours, cellulose-based cadmium sulf...

Embodiment 2

[0029]Weigh 5.13 g of cadmium sulfate and mix it with distilled water, stir until completely dissolved, then take 5 g of cotton washed and dried with absolute ethanol and immerse in the cadmium sulfate solution for 2 hours to make the cotton soaked in the solution, and then put it in a constant temperature Dry in a drying oven at 50 °C for 3 hours; then weigh 1.52 g of thiourea and mix it with distilled water, stir until completely dissolved; add the above-mentioned dried cotton and prepared thiourea solution into the hydrothermal reaction kettle, and tighten the hydrothermal reaction The kettle was placed in a constant temperature drying oven, the reaction temperature was 120°C, and the reaction was carried out for 13 hours. After the reaction is complete, take it out and filter it with Buchner funnel, wash it with distilled water and absolute ethanol three times respectively, then put it in a constant temperature drying oven at 25°C and dry it for 3 hours to obtain cellulose-...

Embodiment 3

[0031] Weigh 9.24 g of cadmium nitrate and mix it with distilled water, stir until it is completely dissolved, then take 9 g of cotton washed and dried with absolute ethanol and soak it in the cadmium nitrate solution for 2 hours, so that the cotton is soaked in the solution, and then put it in a constant temperature Dry in a drying oven at 60°C for 4 hours; then weigh 6.75 g of thioacetamide and mix it with distilled water, and stir until completely dissolved. Add the above-mentioned dried cotton and the prepared thioacetamide solution into the hydrothermal reaction kettle, tighten the hydrothermal reaction kettle and put it into a constant temperature drying oven at a reaction temperature of 130° C. for 14 hours. After the reaction is completed, take it out and filter it with a Buchner funnel, wash it with distilled water and absolute ethanol three times respectively, then put it in a constant temperature drying oven at 30°C and dry it for 3 hours to obtain cellulose-based ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com