Cellulose/nano zinc oxide composite material and preparation method and application thereof

A technology of nano-zinc oxide and composite materials, applied in the photocatalytic degradation of organic pollutants, in the field of cellulose/nano-zinc oxide composite materials and its preparation, can solve surface enrichment, nano-zinc oxide irregular morphology, Problems such as large amount of zinc oxide composite material added

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0099] The preparation method of composite material of the present invention comprises the steps:

[0100] 1) providing a cellulose sol film;

[0101] 2) The cellulose sol film is placed in a zinc salt solution, and the zinc salt solution soaked in the cellulose sol film is heated to obtain the cellulose / nanometer zinc oxide composite material of the present invention.

[0102] Wherein, the cellulose sol film is prepared as follows:

[0103] a) providing a cellulose solution;

[0104] b) coating the defoamed cellulose solution on a slide to obtain the cellulose sol film.

[0105] Specifically, the solvent of the cellulose solution is a mixed solution of sodium hydroxide, urea and water.

[0106] In a preferred example, the mass ratio of sodium hydroxide: urea: water in the solvent is 5-10: 10-15: 70-90.

[0107] Typically, the mass ratio of sodium hydroxide in the solvent: urea is 5-10:10-15.

[0108] Specifically, based on the total weight of the cellulose solution, the ...

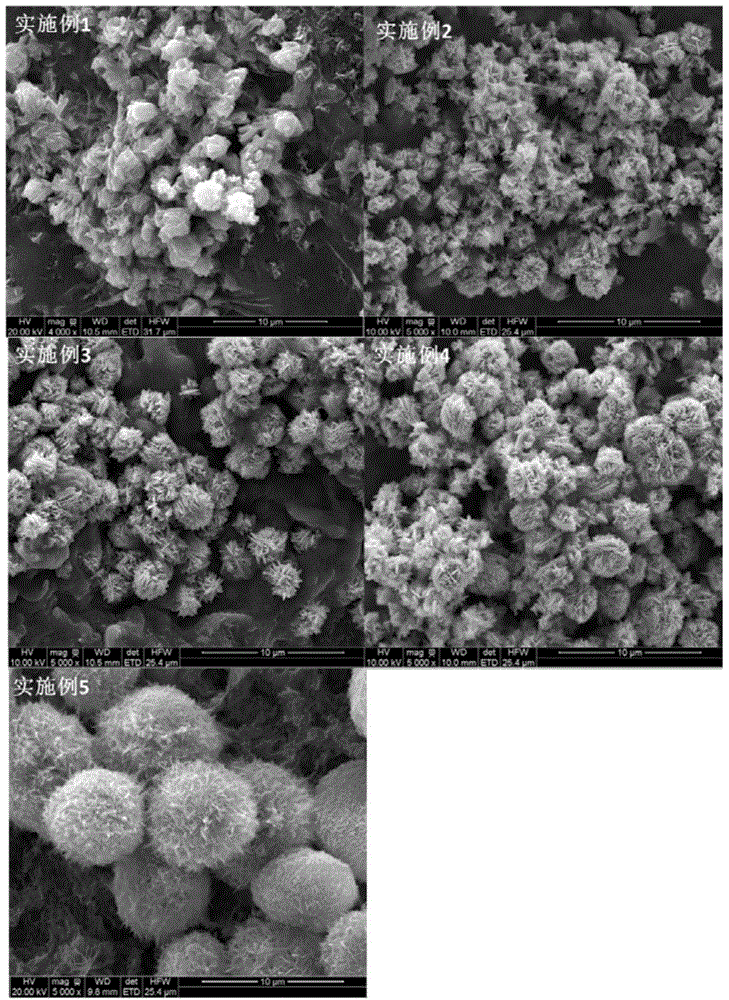

Embodiment 1

[0133] Example 1 Composite material 1

[0134] Use cellulose powder with an average particle size of 50 μm

[0135] Step 1: Prepare the cellulose dissolving solution according to sodium hydroxide: urea: water = 7:12:81 (wt%), and put it into the refrigerator to pre-cool to -5-15°C. Add 8wt% cellulose to the pre-cooled dissolving solution, and stir for 3 minutes at a temperature lower than 5° C. to obtain a uniform and transparent cellulose solution.

[0136] Step 2: Centrifuge and degas the cellulose solution obtained in Step 1, apply a film on a glass slide, and let it stand for 10 minutes.

[0137] Step 3: Immerse the product obtained in Step 2 at room temperature in a 3.5 mM zinc chloride solution and let it stand for 10 hours to form a reverse-phase film of cellulose and nucleate zinc oxide.

[0138] Step 4: wash the resultant of step 3 with deionized water 3-5 times, and air-dry at room temperature to obtain composite material 1

[0139] result

[0140] The surface mo...

Embodiment 2

[0142] Example 2 Composite material 2

[0143] Use cellulose powder with an average particle size of 50 μm

[0144] Step 1: Prepare the cellulose dissolving solution according to sodium hydroxide: urea: water = 7:12:81 (wt%), and put it into the refrigerator to pre-cool to -5-15°C. Add 8wt% cellulose to the pre-cooled dissolving solution, and stir for 3 minutes at a temperature lower than 5° C. to obtain a uniform and transparent cellulose solution.

[0145] Step 2: Centrifuge and degas the cellulose solution obtained in Step 1, apply a film on a glass slide, and let it stand for 10 minutes.

[0146] Step 3: Immerse the product obtained in Step 2 at room temperature in a 3.5 mM zinc chloride solution and let it stand for 10 hours to form a reverse-phase film of cellulose and nucleate zinc oxide.

[0147] Step 4: The product obtained in step 3 was heated at 80° C. for 4 hours, and zinc oxide nanoparticles with a hierarchical structure were grown in situ on the surface of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com