Core-shell type fluorine-and-silicon-containing long carbon chain acrylate water and oil repellent agent

A water- and oil-repellent agent, acrylate technology, applied in the direction of repelling fibers, fiber processing, textiles and paper making, etc. The effect of improving crystallinity and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

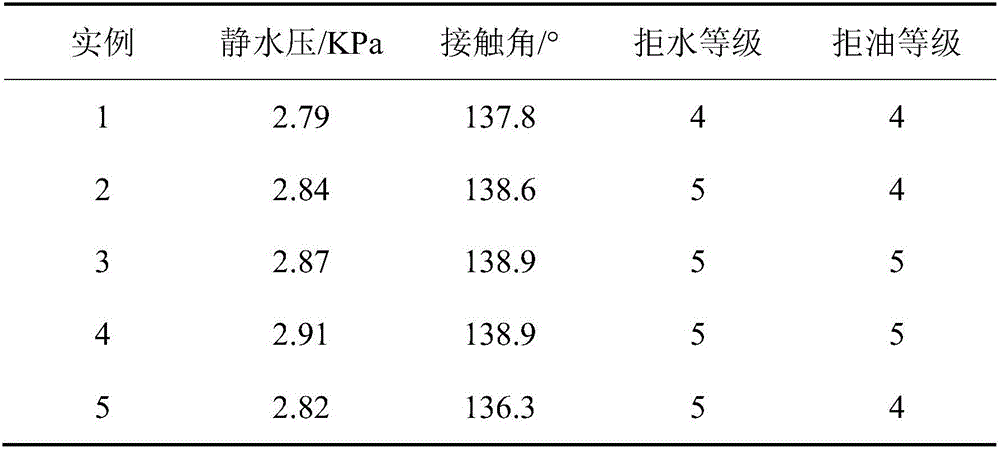

Examples

example 1

[0036] Step 1, weigh 14.9g of hexafluorobutyl acrylate, 1.9g of vinyltrimethoxysilane, 18.4g of isooctyl methacrylate, 4.8g of methyl methacrylate, 0.3g of hydroxyethyl acrylate, 1-ene Propoxy-3-(4-nonylphenol)-2-propanol polyoxyethylene (10) ether ammonium sulfate 0.6g, potassium persulfate 0.4g, deionized water 160g;

[0037] Step 2, preparation of shell emulsion: 14.9g of hexafluorobutyl acrylate, 1.9g of vinyltrimethoxysilane, 7.2g of isooctyl methacrylate, 1-allyloxy-3-(4-nonylphenol )-2-propanol polyoxyethylene (10) ether ammonium sulfate 0.36g, potassium persulfate 0.16g and deionized water 96g are added in the generator, stirred for 30min under the action of the stirrer, the stirring speed is 2000r / min, and then Pour the mixed solution into a high-shear dispersing emulsifier for high-speed emulsification. The emulsification time is 10 minutes, and the speed of the high-shear dispersing emulsifier is 7000 / min, and the shell emulsion is prepared for use;

[0038] Step 3...

example 2

[0041] Step 1, weigh 22.4g of dodecafluoroheptyl acrylate, 2.8g of vinyltriethoxysilane, 27.6g of lauryl methacrylate, 4.8g of butyl acrylate, 0.5g of hydroxypropyl acrylate, 1-allyl Oxy-3-(4-nonylphenol)-2-propanol polyoxyethylene (10) ether monophosphoric acid 1.2g, azobisisobutyronitrile 0.6g, deionized water 140g;

[0042] Step 2, preparation of shell emulsion: 22.4g of dodecafluoroheptyl acrylate, 2.8g of vinyltriethoxysilane, 10.8g of lauryl methacrylate, 1-allyloxy-3-(4-nonyl Add 0.72g of phenol)-2-propanol polyoxyethylene (10) ether monophosphoric acid, 0.24g of azobisisobutyronitrile and 84g of deionized water into the generator, stir for 30min under the action of a stirrer, and the stirring speed is 2000r / min, then pour the mixed solution into a high-shear dispersing emulsifier for high-speed emulsification, the emulsification time is 10min, and the rotating speed of the high-shear dispersing emulsifier is 7000r / min, and the shell emulsion is obtained for use;

[0...

example 3

[0046] Step 1, weigh 18.7g of dodecafluoroheptyl methacrylate, 2.3g of methylvinyldiethoxysilane, 23g of hexadecyl methacrylate, 6g of methyl methacrylate, 1-allyl Oxy-3-(4-nonylphenol)-2-propanol polyoxyethylene (10) ether ammonium sulfate 0.75g, ammonium persulfate 0.5g, deionized water 150g.

[0047] Step 2, preparation of shell emulsion: add 18.7 g of dodecafluoroheptyl methacrylate, 2.3 g of methylvinyldiethoxysilane, 9 g of hexadecyl methacrylate, 1-ene Propoxy-3-(4-nonylphenol)-2-propanol polyoxyethylene (10) ether ammonium sulfate 0.45g, ammonium persulfate 0.2g and deionized water 90g, stirred under the action of a stirrer for 30min, The stirring speed is 2000r / min, and then the mixed solution is poured into a high-shear dispersing emulsifier for high-speed emulsification. The emulsification time is 10 minutes, and the speed of the high-shear dispersing emulsifier is 7000 / min, and the shell emulsion is prepared for use;

[0048] Step 3, preparation of nuclear emulsio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com