A three-dimensional crosslinked attapulgite/graphene/polyaniline composite anticorrosion material and its preparation method

A technology of attapulgite and anti-corrosion materials, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as curling and agglomeration, improve anti-corrosion performance, prevent stacking and agglomeration, and enhance mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

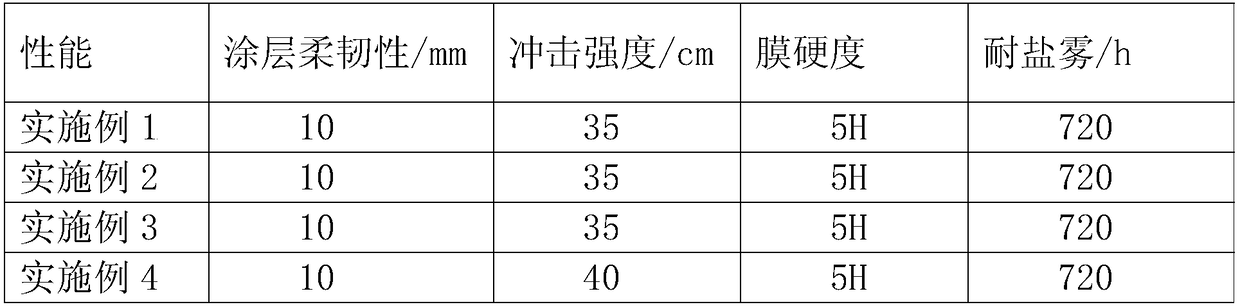

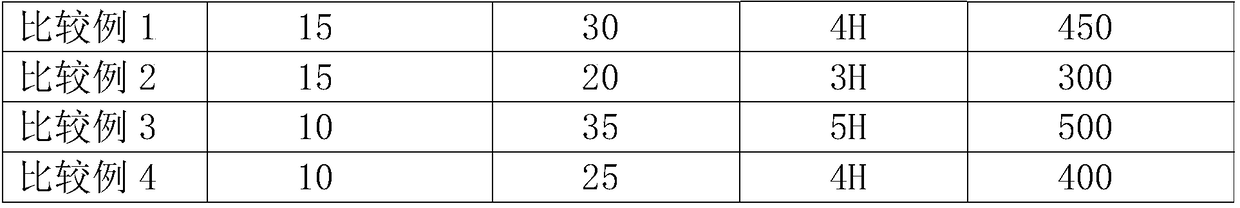

Examples

Embodiment 1

[0012] 1. Add 0.5 kg of amino-modified attapulgite and 2.5 kg of graphite oxide into 12.0 kg of deionized water respectively. After ultrasonic dispersion for 0.5 hours, while stirring, add 0.9 kg of aniline and 0.18 kg of nitrilotriacetic acid in turn, and place in 0 ℃ in ice water bath;

[0013] 2. Add dropwise 4.8 liters of ammonium persulfate solution with a molar concentration of 1.0 mol / liter to the dispersion obtained in step 1 to carry out oxidative polymerization and cross-linking reaction. After the dropwise addition is completed, stir and react at a constant temperature for 3.0 hours; filter, wash, freeze-dry , and pulverize to obtain a three-dimensional cross-linked attapulgite / graphene / polyaniline composite anticorrosion material.

Embodiment 2

[0015] 1. Add 2.0 kg of amino-modified attapulgite and 0.4 kg of graphite oxide into 48.0 kg of deionized water respectively. After ultrasonic dispersion for 2 hours, while stirring, add 2.4 kg of aniline and 1.5 kg of nitrilotriacetic acid in turn, and place in 4 ℃ in ice water bath;

[0016] 2. Add 12.9 liters of ammonium persulfate solution with a molar concentration of 4.0 mol / liter dropwise to the dispersion obtained in step 1 to carry out oxidative polymerization and crosslinking reaction. After the addition is completed, stir and react at a constant temperature for 6.0 hours; filter, wash, freeze-dry , and pulverize to obtain a three-dimensional cross-linked attapulgite / graphene / polyaniline composite anticorrosion material.

Embodiment 3

[0018] 1. Add 2.5 kg of amino-modified attapulgite and 1.0 kg of graphite oxide into 23.3 kg of deionized water respectively. After ultrasonic dispersion for 1.25 hours, while stirring, add 2.3 kg of aniline and 0.95 kg of nitrilotriacetic acid in sequence, and place in 2.5 ℃ in ice water bath;

[0019] 2. Add dropwise 12.3 liters of ammonium persulfate solution with a molar concentration of 2.0 mol / liter to the dispersion obtained in step 1 to carry out oxidative polymerization and cross-linking reaction. After the dropwise addition is completed, stir and react at a constant temperature for 4.5 hours; filter, wash, freeze-dry , and pulverize to obtain a three-dimensional cross-linked attapulgite / graphene / polyaniline composite anticorrosion material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com