Preparation method of polyaniline/carboxylated graphene composite material

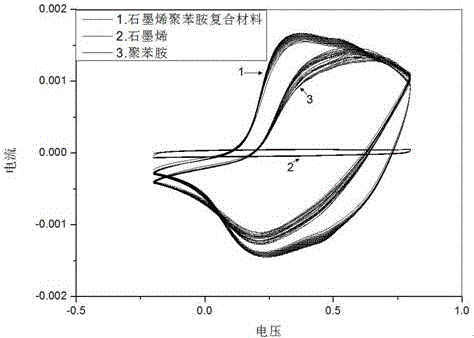

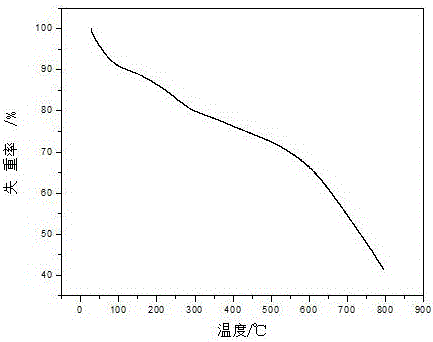

A technology of carboxylated graphene and composite materials, applied in the field of composite materials, can solve the problems of limited charge storage capacity and easy oxidation of molecular chains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

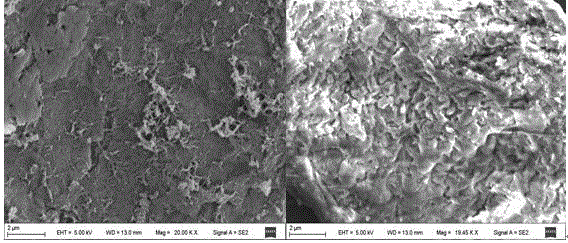

[0033] The preparation, structure, and morphology of the polyaniline / carboxylated graphene composite material of the present invention will be further described through specific examples below.

[0034] (1) Preparation of graphite oxide

[0035] Weigh 0.5g flake graphite, add 4.5g potassium permanganate into a three-necked flask and mix well. Measure 7.5ml of concentrated phosphoric acid into the beaker, measure 60ml of concentrated sulfuric acid and slowly pour it into the concentrated phosphoric acid. Place the three-neck flask in an ice-water bath and stir. Slowly add the above mixed acid, stir and react at 30~40°C for 1h, then raise the temperature to 50°C and continue the reaction for 12h. Cool to room temperature after the reaction, slowly pour the reaction product into ice water containing 10mL of hydrogen peroxide, let it stand, pour off the supernatant, filter with suction, and wash the filter cake with 5% hydrochloric acid until there is no SO in the filtrate. 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com