Flame-retardant and fire-resistant ceramic silicone rubber and preparation method thereof

A ceramic silicone rubber, flame retardant and fire-resistant technology, applied in the field of rubber materials, can solve the problems of difficult liquid phase ceramicization, unsatisfactory ceramicization effect, increased shrinkage, etc., achieve low production cost, avoid the decline of insulation performance, The effect of promoting fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

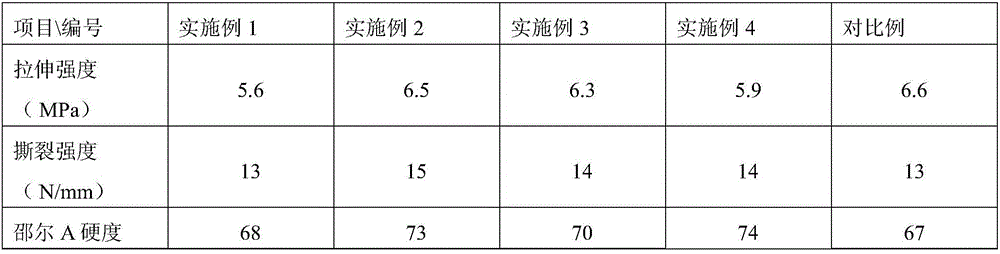

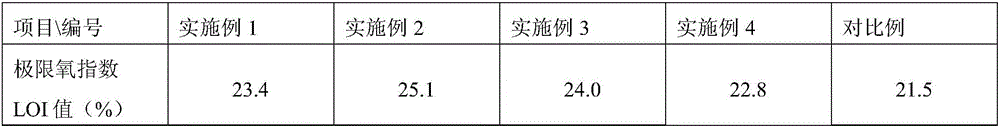

Examples

Embodiment 1

[0049] A method for preparing flame-retardant refractory vitrified silicone rubber, comprising the following steps:

[0050] (1) Roll 100 parts of methyl vinyl silicone rubber (vinyl content is 0.16mol%, average molecular weight is 650,000), add 30 parts of Toyo K-200 fumed silica and 5 parts of hydroxy silicone oil (hydroxy content is 8wt%), mixing evenly;

[0051] (2) Add 2 parts of silane coupling agent A171 and 75 parts of porcelain powder to the mixed rubber obtained in step (1), and knead evenly;

[0052] (3) Add 20 parts of aluminum hydroxide flame retardant, 5 parts of zinc oxide, 0.001 part of chloroplatinic acid and 4 parts of heat-resistant agent iron oxide in the mixed rubber obtained in step (2), and mix evenly;

[0053] (4) Add 9 parts of phenolic resin, 1 part of polyester fiber and 0.5 part of C glue (polyvinyl silicone oil with a vinyl content of 8mol%) to the mixed rubber obtained in step (3), and mix evenly;

[0054] (5) heat-treat the mixed rubber obtaine...

Embodiment 2

[0059] A method for preparing flame-retardant refractory vitrified silicone rubber, comprising the following steps:

[0060] (1) Roll 100 parts of methyl vinyl silicone rubber (vinyl content is 0.22mol%, average molecular weight is 650,000), add 40 parts of Cabot TS-530 white carbon black and 0.5 parts of hydroxy silicone oil (hydroxyl content is 8wt%), mixing evenly;

[0061] (2) Add 2.5 parts of silane coupling agent KH570 and 85 parts of porcelain powder to the mixed rubber obtained in step (1), and mix evenly;

[0062] (3) Add 15 parts of flame retardants, 0.0006 parts of chloroplatinic acid, 6 parts of zinc oxide and 3 parts of cerium oxide heat-resistant agents to the mixed rubber obtained in step (2), and mix evenly;

[0063] (4) Add 12 parts of polysulfone resin and 1 part of C glue (polyvinyl silicone oil with a vinyl content of 8mol%) to the mixed rubber obtained in step (3), and mix evenly;

[0064] (5) heat-treat the mixed rubber obtained in step (4) in an oven a...

Embodiment 3

[0070] A method for preparing flame-retardant refractory vitrified silicone rubber, comprising the following steps:

[0071] (1) Roll 100 parts of methyl vinyl silicone rubber (the vinyl content is 1.6mol%, and the average molecular weight is 800,000), add 35 parts of Degussa A200 type white carbon black and 3.5 parts of hydroxyl silicone oil (the hydroxyl content is 6wt%), uniform mixing;

[0072] (2) Add 3 parts of silane coupling agent KH550 and 75 parts of porcelain powder to the mixed rubber obtained in step (1), and knead evenly;

[0073] (3) Add 15 parts of flame retardant, 0.05 part of tetramethyldivinyldisiloxane-platinum complex, 8 parts of zinc oxide and 5 parts of heat-resistant agent in the rubber compound obtained in step (2) , mixed evenly;

[0074] (4) Add 10 parts of polyurethane resin, 2 parts of aramid fibers and 1 part of C glue (polyvinyl silicone oil with a vinyl content of 8mol%) to the mixed rubber obtained in step (3), and mix evenly;

[0075] (5) h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com