Method for producing volatile fatty acid (VFA) from mushroom cultured residue through alkaline fermentation

A technology for volatile fatty acids and mushroom residues, which is applied in the field of organic solid waste recycling, can solve problems such as land occupation and secondary environmental pollution, and achieve the effects of low operating cost, restraining consumption and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

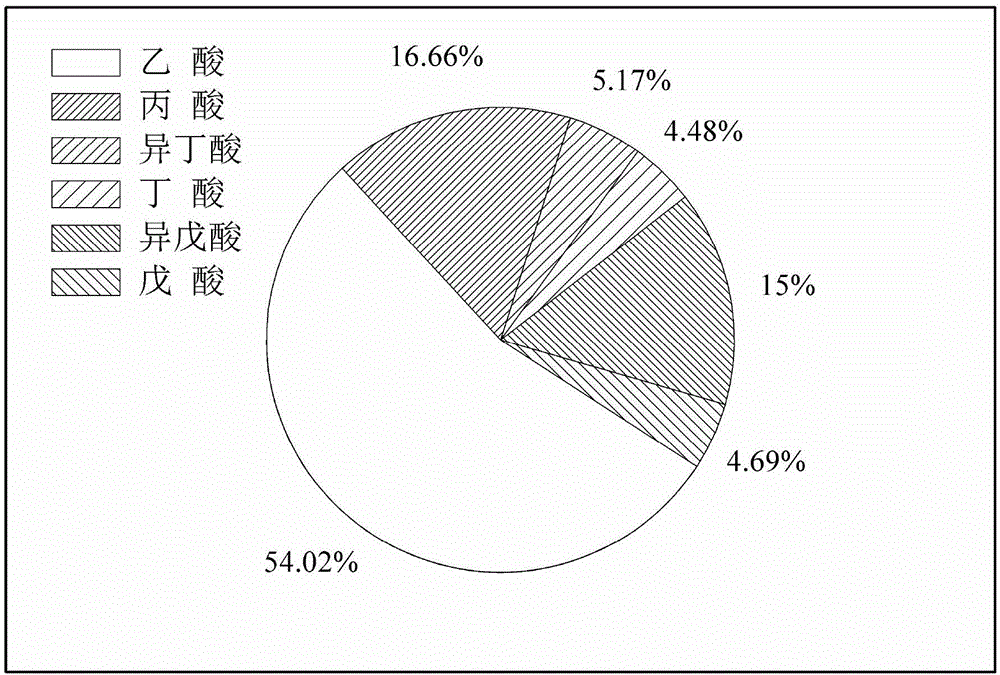

Image

Examples

Embodiment 1

[0019] (1) Take a certain amount of mushroom slag from a certain mushroom factory, its C / N=28.69, dry it in an oven at 105°C for 24 hours, then mechanically crush it, sieve it, the particle size is 1.0-0.5cm, and the sieved mushroom dregs as fermentation substrate;

[0020] (2) get the mushroom dregs that obtain in step (1) and put into fermenter, add distilled water and be configured into the mixed solution that solid content rate is 12%; Add inoculated sludge in mixed solution, mixed solution volume and inoculated sludge volume The ratio is 5:1;

[0021] (3) Pass nitrogen into the fermenter of step (2) for 5 minutes and then seal it, and ferment under anaerobic conditions. Control the mechanical stirring speed at 120r / min, control the temperature at 35±1℃, and after anaerobic fermentation for 5 days, the concentration of VFA produced is the highest, which is 2274.16mg / L.

Embodiment 2

[0023] (1) Take a certain amount of mushroom slag from a mushroom factory, its C / N=28.69, dry it in an oven at 105°C for 24 hours, then mechanically pulverize it, sieve it, the particle size is 0.5-0.3cm, and the sieved mushroom dregs as fermentation substrate;

[0024] (2) get the mushroom dregs that obtain in step (1) and put into fermenter, add distilled water and be configured into the mixed solution that solid content rate is 15%; Add inoculated sludge in mixed solution, mixed solution volume and inoculated sludge volume The ratio is 5:1;

[0025] (3) Pass nitrogen into the fermenter of step (2) for 5 minutes and then seal it, and ferment under anaerobic conditions. Control the speed of mechanical stirring at 120r / min, control the temperature at 35±1℃, and after 5 days of anaerobic fermentation, the concentration of VFA produced is the highest, which is 2657.58mg / L.

Embodiment 3

[0027] (1) Take a certain amount of mushroom slag from a certain mushroom factory, its C / N=28.69, dry it in an oven at 105°C for 24 hours, then mechanically crush it, sieve it, the particle size is 1.0-0,5cm, and the sieved mushroom dregs as fermentation substrate;

[0028] (2) get the mushroom dregs that obtain in step (1) and put into fermenter, add distilled water and be configured into the mixed solution that solid content rate is 15%; Add inoculated sludge in mixed solution, mixed solution volume and inoculated sludge volume The ratio is 5:1;

[0029] (3) Pass nitrogen into the fermenter of step (2) for 5 minutes and then seal it, and ferment under anaerobic conditions. Control the mechanical stirring speed at 120r / min, control the temperature at 35±1°C, add 1.0mol / L NaOH solution during the entire anaerobic fermentation process, and maintain the pH of the fermentation system at about 10. After 5 days of anaerobic fermentation, the produced The concentration of VFA is t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com