A flexible fully transparent amorphous oxide thin film transistor and its preparation method

An amorphous oxide, thin film transistor technology, used in transistors, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve the problems of low resistivity, poor device stability, reduced on-state current, etc., and achieve good electrical performance. , the effect of high visible light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

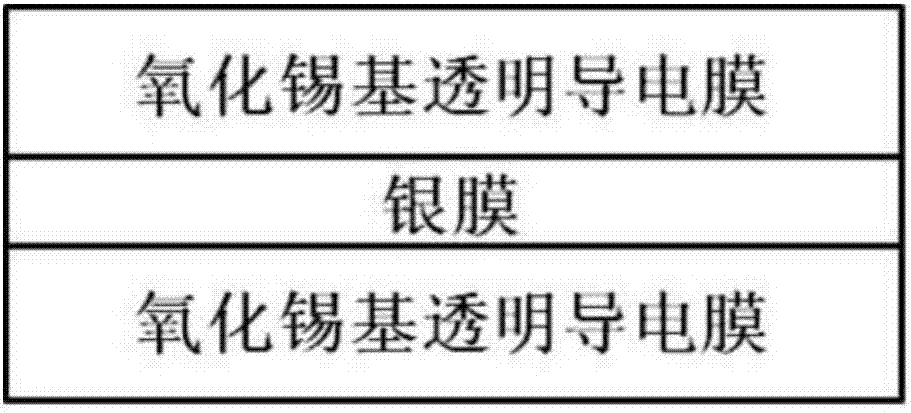

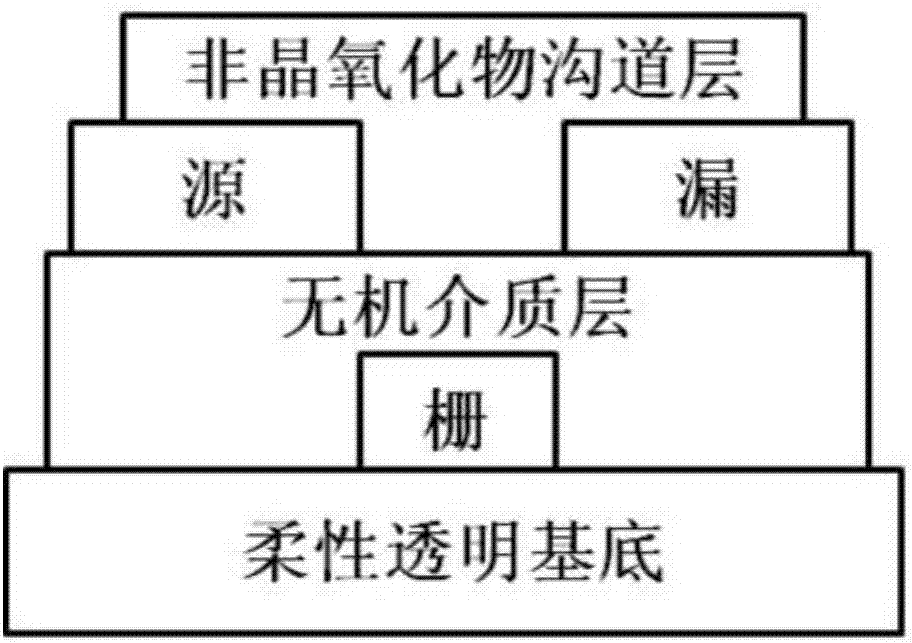

[0037] Using PET as the substrate, amorphous indium gallium zinc oxide (In-Ga-Zn-O) film as the channel layer, inorganic Al 2 o 3 The thin film is used as the dielectric layer, the ITO thin film is used as the gate electrode layer, and the molybdenum (Mo)-doped SnO 2 A silver-based transparent conductive multilayer film composed of transparent conductive oxide and silver film (SnO 2 : Mo / Ag / SnO 2 : Mo) as the source / drain electrode layer, the structure of the silver-based transparent conductive multilayer film is as figure 1 As shown, a flexible fully transparent amorphous oxide TFT with a bottom gate coplanar structure is prepared, and the structure of the flexible fully transparent amorphous oxide TFT is as follows figure 2 As shown, the specific steps are as follows:

[0038] (1) Use radio frequency magnetron sputtering method on the PET substrate to form an ITO film with a thickness of 80nm with the aid of an aluminum oxide mask. The target material is an ITO ceramic ...

Embodiment 2

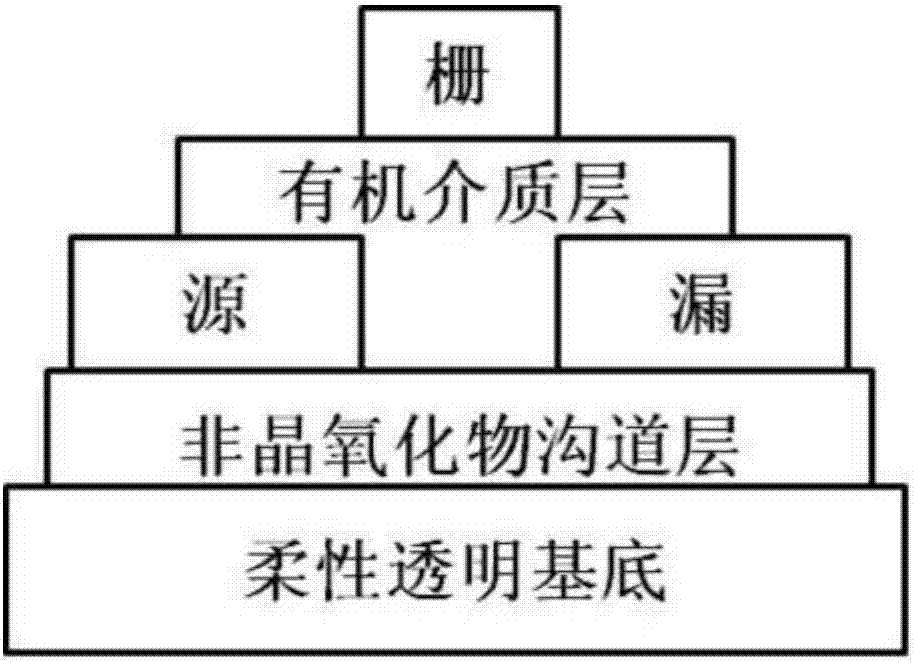

[0044] Using PET as the substrate, amorphous indium gallium zinc oxide (In-Ga-Zn-O) film as the channel layer, organic PMMA film as the dielectric layer, ITO film as the gate electrode layer, molybdenum (Mo) SnO 2 A silver-based transparent conductive multilayer film composed of transparent conductive oxide and silver film (SnO 2 : Mo / Ag / SnO 2 : Mo) as the source / drain electrode layer, the structure of the silver-based transparent conductive multilayer film is as figure 1 As shown, a flexible fully transparent amorphous oxide TFT with a coplanar top gate structure is prepared, and the structure of the flexible fully transparent amorphous oxide TFT is as follows image 3 As shown, the specific steps are as follows:

[0045] (1) An amorphous indium gallium zinc oxide film with a thickness of 50nm is formed on a PET substrate by radio frequency magnetron sputtering. The target material is an indium gallium zinc oxide target with a purity of 4N. The sputtering power is 20W and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com