A carbon-silicon composite material for lithium-ion batteries and its preparation method and application

A technology of carbon composite materials and lithium-ion batteries, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as unstable SEI films, and achieve the effects of environmental friendliness, low production costs, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

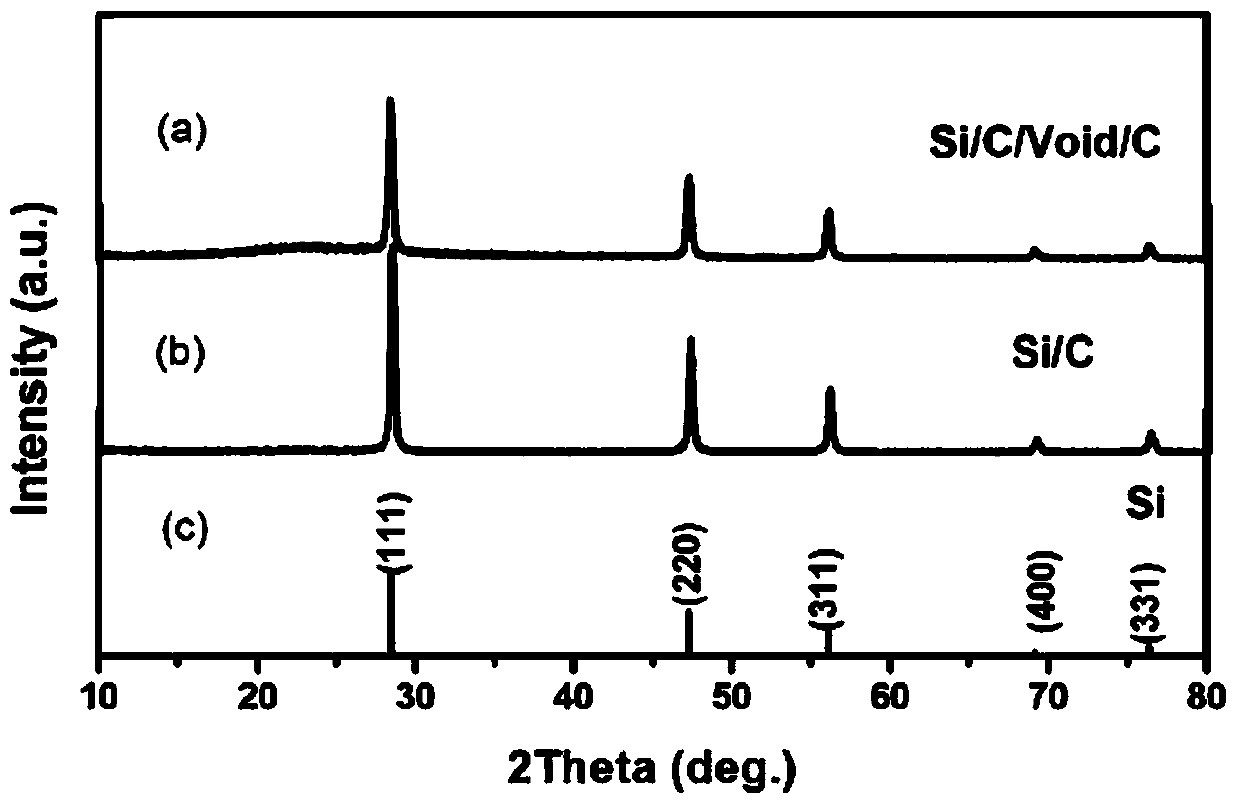

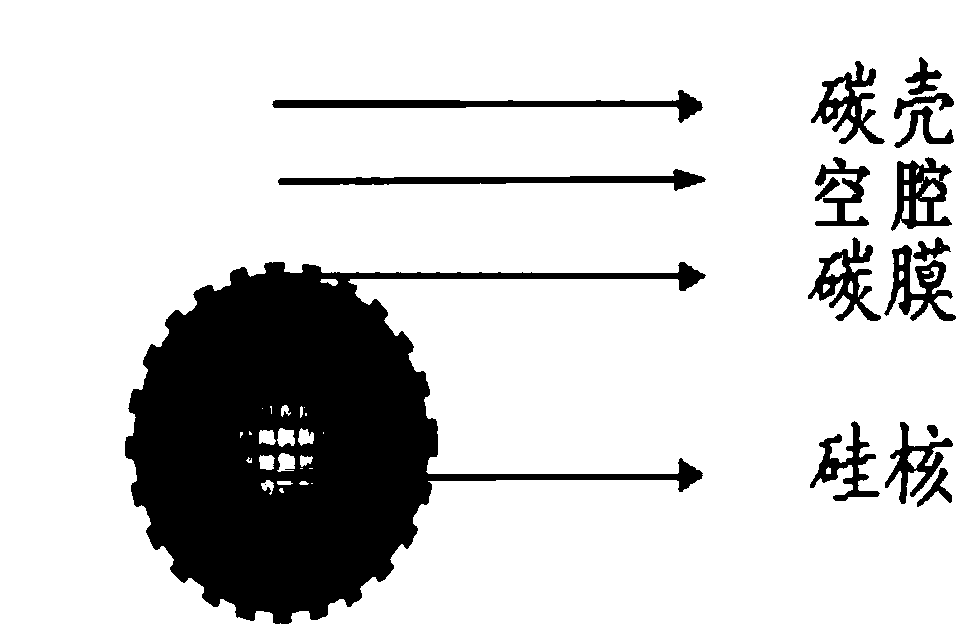

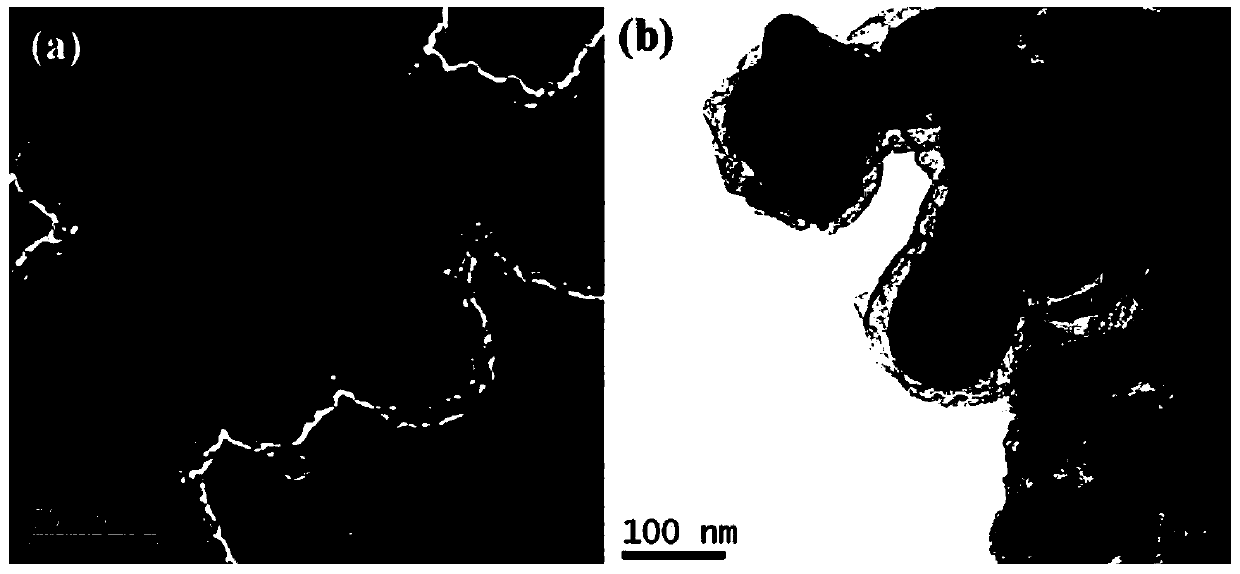

[0037] Mix commercial Si and PVP at a mass ratio of 5:1, add alcohol 10 times the mass of PVP, stir, and then dry in a drying oven at 70°C. After drying, carbonize at 550°C for 1h under Ar atmosphere. Add a certain amount of the obtained Si / C core-shell structure product and PVP into the mixed solution of ethanol and deionized water, stir after ultrasonic oscillation, add 3mL ammonia water and tetraethyl orthosilicate (TEOS) with 3.33 times the mass of Si / C during the stirring process, and stir One hour. Put the obtained liquid into a centrifuge to collect the product by centrifugation, and then dry it in a drying oven at 70°C to obtain Si / C / SiO 2 product. Si / C / SiO 2 Mix with PVP at a mass ratio of 5:1, add alcohol and stir, then place in a drying oven to dry at 70°C, and then carbonize at 600°C for 1 hour under Ar atmosphere after drying. The obtained product was etched in 0.4Mol / L NaOH and then centrifuged and dried. The obtained product had a Si / C / void / C composite struct...

Embodiment 2

[0039] Mix commercial Si and PVP at a mass ratio of 2:1, add alcohol 0.5 times the mass of PVP, stir, and then dry in a drying oven at 70°C. After drying, carbonize at 800°C for 1h under Ar atmosphere. Add a certain amount of the obtained Si / C core-shell structure product and PVP into the mixed solution of ethanol and deionized water, stir after ultrasonic oscillation, add 3mL ammonia water and tetraethyl orthosilicate (TEOS) 0.33 times the mass of Si / C during the stirring process, and stir One hour. Put the obtained liquid into a centrifuge to collect the product by centrifugation, and then dry it in a drying oven at 70°C to obtain Si / C / SiO 2 product. Si / C / SiO 2 Mix with PVP at a mass ratio of 3:1, add alcohol and stir, and then dry in a drying oven at 70°C. After drying, carbonize at 550°C for 1 hour under Ar atmosphere. The obtained product was etched in 5Mol / L NaOH and then centrifuged and dried. The obtained product had a Si / C / void / C composite structure. Si accounts f...

Embodiment 3

[0041] Mix commercial Si and PVP at a mass ratio of 4:1, add alcohol 5 times the mass of PVP, stir, and then dry in a drying oven at 70°C. After drying, carbonize at 700°C for 1 hour in an Ar atmosphere. Add a certain amount of the obtained Si / C core-shell structure product and PVP into the mixed solution of ethanol and deionized water, stir after ultrasonic oscillation, add 3mL ammonia water and tetraethyl orthosilicate (TEOS) twice the mass of Si / C during the stirring process, and stir One hour. Put the obtained liquid into a centrifuge to collect the product by centrifugation, and then dry it in a drying oven at 70°C to obtain Si / C / SiO 2 product. Si / C / SiO 2 Mix with PVP at a mass ratio of 2:1, add alcohol and stir, then place in a drying oven to dry at 70°C, and then carbonize at 650°C for 1 hour under Ar atmosphere after drying. The obtained product was etched in 1Mol / L NaOH and then centrifuged and dried. The obtained product had a Si / C / void / C composite structure. Si ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com