A kind of concrete and preparation method thereof

A concrete and mixture technology, applied in the field of concrete, can solve the problems of occupying cultivated land, polluting the environment, and losing activity of the soil, and achieves the effects of stable spatial structure, low thermal conductivity, and good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

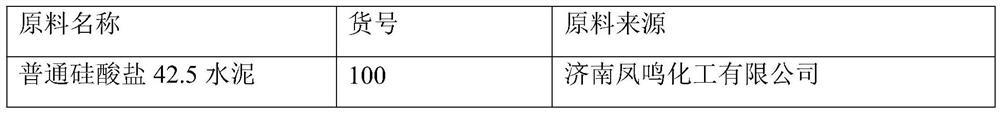

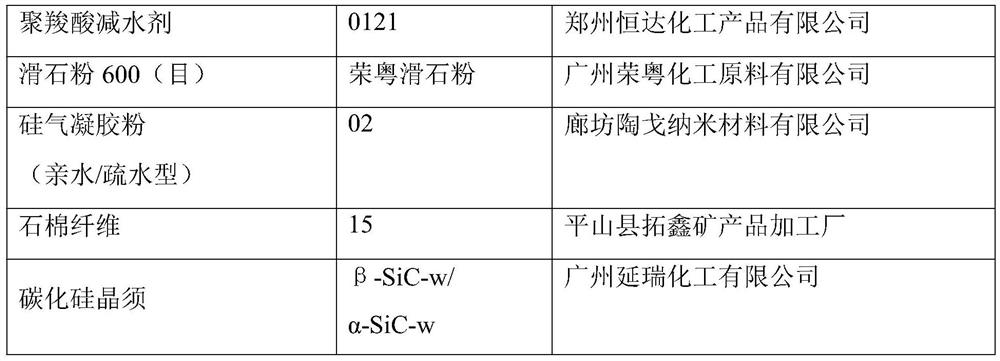

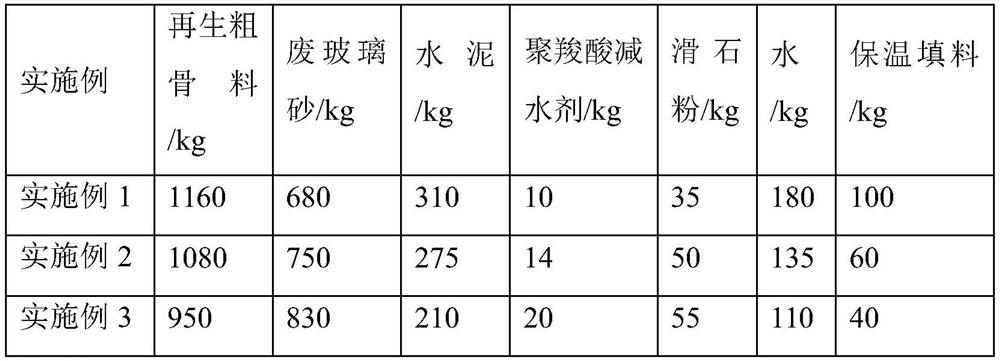

Method used

Image

Examples

preparation example 1

[0051] In this preparation example, the silicon aerogel powder is selected from hydrophilic silicon aerogel powder with a particle size of 1.2 mm; the silicon carbide whisker is selected from beta-type silicon carbide whisker, and the whisker length is 35 μm. The whisker diameter is 0.15 μm; the asbestos fiber is 18 mm asbestos fiber. The thermal insulation filler is specifically made by the following methods:

[0052] S1: When 35kg of silicon aerogel powder is placed in a plasma surface treatment machine, the processing gas includes argon 150SCCM; nitrogen 100SCCM, and the silicon aerogel powder is surface-treated for 60s under the condition of vacuum degree of 45Pa

[0053] S2: after weighing 5kg of asbestos fibers and 1kg of silicon carbide whiskers, in a powder particle mixer, stir at a speed of 500r / min until uniformly mixed to obtain a dry powder mixture;

[0054] S3: Divide the silicon aerogel powder obtained after the treatment in step S1 into 4 equal parts, each equa...

preparation example 2-4

[0057] The difference between Preparation Example 2-4 and Preparation Example 1 is that the weight ratio of silicon aerogel powder, asbestos fiber and silicon carbide whisker is different.

[0058] Table 2. Preparation example 2-4 raw material weight parts and proportioning table

[0059] component Preparation Example 1 Preparation Example 2 Preparation Example 3 Preparation Example 4 Silicon aerogel powder / kg 35 18 25 32 Asbestos fiber / kg 5 15 10 6 Silicon carbide whiskers / kg 1 1 1 1 ratio by weight 35:5:1 18:15:1 25:10:1 32:6:1

preparation example 5

[0061] The difference between this preparation example and preparation example 4 is that the silicon aerogel powder in this preparation example is hydrophobic silicon aerogel powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com