Concrete and preparation method thereof

A concrete and mixture technology, applied in the field of concrete, can solve the problems of soil loss of activity, pollution of the environment, occupation of cultivated land, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

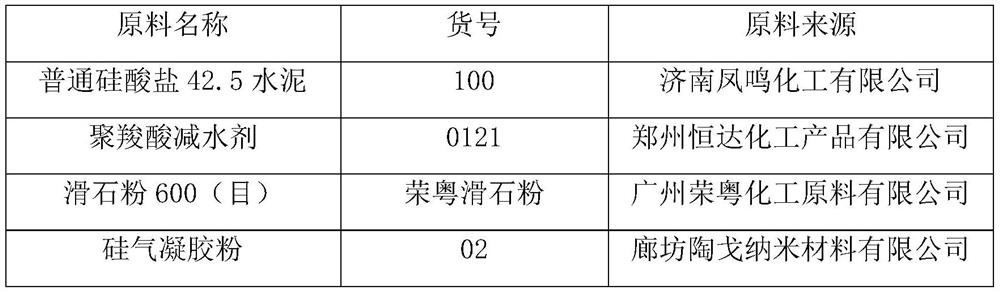

Method used

Image

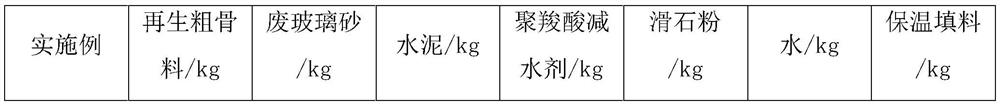

Examples

preparation example 1

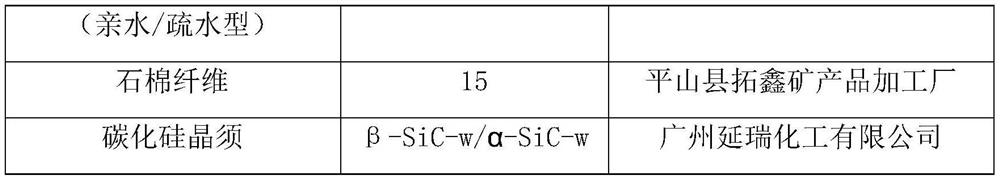

[0051] In this preparation example, the silicon airgel powder is made of hydrophilic silicon airgel powder with a particle size of 1.2mm; The diameter of the whiskers is 0.15 μm; the asbestos fiber is selected as the asbestos fiber with a fiber fiber size of 18 mm. The insulation filler is specifically made by the following methods:

[0052] S1: When 35kg of silicon airgel powder is placed in a plasma surface treatment machine for treatment, the processing gas includes argon 150SCCM; nitrogen 100SCCM, and the silicon airgel powder is surface treated for 60s under the condition of a vacuum of 45Pa

[0053] S2: After weighing 5 kg of asbestos fibers and 1 kg of silicon carbide whiskers, stir in a powder particle mixer at a speed of 500 r / min until uniformly mixed to obtain a dry powder mixture;

[0054] S3: Divide the silicon airgel powder obtained in the step S1 into 4 equal parts, each divided into 8.75kg, add it into the powder particle mixer of S2 in 4 times, stir at a spee...

preparation example 2-4

[0057] The difference between Preparation Examples 2-4 and Preparation Example 1 is that the weight ratios of silica airgel powder, asbestos fibers and silicon carbide whiskers are different, and the weight parts and proportioning ratios are shown in Table 2.

[0058] Table 2. Preparation example 2-4 raw material parts by weight and proportioning table

[0059] components Preparation Example 1 Preparation example 2 Preparation example 3 Preparation Example 4 Silica airgel powder / kg 35 18 25 32 Asbestos fiber / kg 5 15 10 6 SiC whisker / kg 1 1 1 1 Ratio of parts by weight 35:5:1 18:15:1 25:10:1 32:6:1

preparation example 5

[0061] The difference between this preparation example and preparation example 4 is that the silica airgel powder in this preparation example is hydrophobic silica airgel powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Whisker length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com