Nitrogen-rich hierarchical pore carbon material and preparation method

A technology of multi-level pores and carbon materials, used in structural parts, electrical components, battery electrodes, etc., can solve the problems of few active sites, can not reflect performance, no micropores, etc., and achieve the effect of reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: Preparation of nitrogen-rich porous carbon material with cyclohexane and ethanol as reaction solvent

[0026] Take 8 mL of cyclohexane and 20 mL of ethanol in a two-necked flask, control the temperature at 60 °C, mix and disperse evenly for 1 h, add 0.5 g of aniline and disperse for 30 min, then add 1 mL of formaldehyde, and react for 5 h. After the reaction, The obtained product was washed three times with deionized water and three times with cyclohexane, and dried at 80° C. to obtain a nitrogen-rich porous polymer material. Under the protection of inert gas, the purified product was carbonized at 800 °C for 3 h to obtain a nitrogen-rich hierarchical porous carbon material.

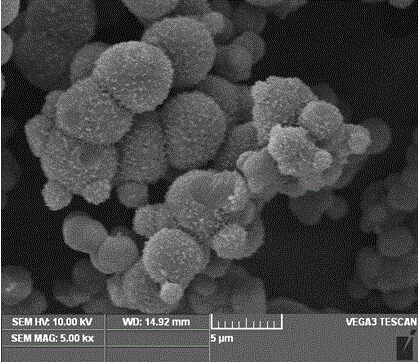

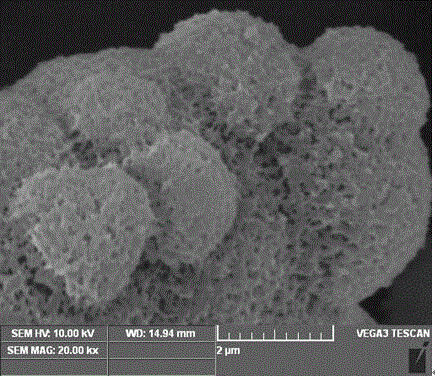

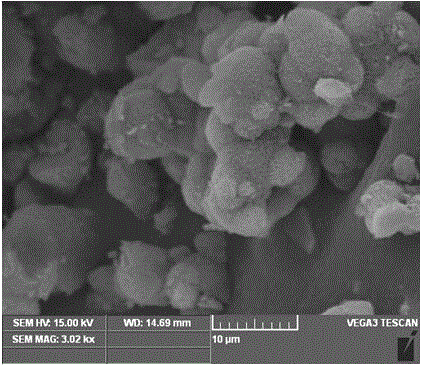

[0027] The product was scanned by an electron microscope and identified as having a porous structure. Nitrogen adsorption-desorption proves that it contains hierarchical pore structure and pore distribution.

Embodiment 2

[0028] Embodiment 2: Preparation of nitrogen-rich porous carbon material with isopropanol and water as reaction solvent

[0029] Take 20 mL of isopropanol and 8 mL of water in a two-necked flask, control the temperature at 70 °C, mix and disperse evenly for 1 h, add 0.5 g of m-phenylenediamine and disperse for 30 min, then add 1 mL of formaldehyde, react for 5 h, and react After the end, the obtained product was washed three times with deionized water and three times with cyclohexane, and dried at 80° C. to obtain a nitrogen-rich porous polymer material. Under the protection of inert gas, the purified product was carbonized at 800 °C for 3 h to obtain a nitrogen-rich hierarchical porous carbon material.

[0030] The product was scanned by an electron microscope and identified as having a porous structure. Nitrogen adsorption-desorption proves that it contains hierarchical pore structure and pore distribution.

Embodiment 3

[0031] Example 3: Preparation of nitrogen-rich porous carbon material with tetrahydrofuran and water as reaction solvent

[0032] Take 20 mL of tetrahydrofuran and 8 mL of water in a two-necked flask, control the temperature at 60 °C, mix and disperse evenly for 1 h, add 0.5 g of aniline and disperse for 30 min, then add 1 mL of formaldehyde, and react for 5 h. After the reaction, the obtained product After washing three times with deionized water and three times with cyclohexane, and drying at 80°C, a nitrogen-rich porous polymer material is obtained. Under the protection of inert gas, the purified product was carbonized at 600 °C for 3 h to obtain a nitrogen-rich hierarchical porous carbon material.

[0033] The product was scanned by an electron microscope and identified as having a porous structure. Nitrogen adsorption-desorption proves that it contains hierarchical pore structure and pore distribution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com