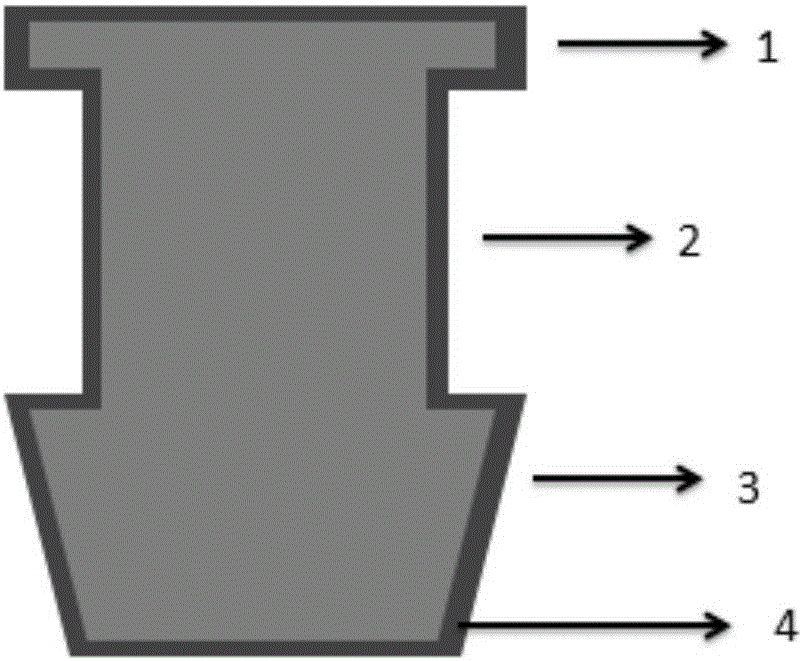

Super-lubricating serum albumin punctal plug and preparation method thereof

A technology of serum albumin and punctal plug, which is applied in the field of medical devices, can solve the problems of not being able to reach the eyes with tears, blockage of lacrimal ducts, and outflow of tears, so as to relieve pain, reduce injuries and prevent complications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Prepare a solution system for dissolving serum albumin: take each component according to volume percentage, 0.1M ammonia water 10%, 1% mercaptoethanol, and the rest is trifluoroethanol, stir to make it fully mixed; dissolve serum albumin in the above solution, Contain 25% (w / v) serum albumin in the final serum albumin solution, gently stir with a magnetic bar for 30 minutes, use a vacuum pump to pump air for 30 minutes to eliminate the bubbles; leave the serum albumin solution at room temperature, after 48h, pour Remove the upper layer of liquid, add the lower layer of serum albumin solution with higher viscosity into the mold, and dry it overnight in the air at room temperature; open the mold, take it out, soak it in the succinimide propionate-based polyethylene glycol solution, The concentration is 10% (w / v), washed with deionized water to pH = 7.0, and dried at 25° C. to prepare super-lubricating serum albumin punctal plugs.

Embodiment 2

[0029] Prepare a solution system for dissolving serum albumin: take each component according to volume percentage, 0.1M ammonia water 10%, 1% mercaptoethanol, and the rest is trifluoroethanol, stir to make it fully mixed; dissolve serum albumin in the above solution, Contain 35% (w / v) serum albumin in the final serum albumin solution, gently stir with a magnetic bar for 30 minutes, and use a vacuum pump to pump air for 30 minutes to eliminate the bubbles; leave the serum albumin solution at room temperature, after 48 hours, pour Remove the upper layer of liquid, add the lower layer of serum albumin solution with higher viscosity into the mold, and dry it overnight in the air at room temperature; open the mold, take it out, soak it in the succinimide propionate-based polyethylene glycol solution, The concentration was 10% (w / v), washed with deionized water to pH = 7.0, and dried at 37° C. to prepare super-lubricating serum albumin punctal plugs.

Embodiment 3

[0031] Prepare a solution system for dissolving serum albumin: take each component according to volume percentage, 0.1M ammonia water 10%, 1% mercaptoethanol, and the rest is trifluoroethanol, stir to make it fully mixed; dissolve serum albumin in the above solution, The final serum albumin solution contains 45% (w / v) serum albumin, stirred gently with a magnetic bar for 30 minutes, and evacuated with a vacuum pump for 30 minutes to eliminate the bubbles; the serum albumin solution was allowed to stand at room temperature, and after 48 hours, poured Remove the upper layer of liquid, add the lower layer of serum albumin solution with higher viscosity into the mold, and dry it in the air at room temperature overnight; open the mold, take it out, soak it in the succinimide succinate-based polyethylene glycol solution, The concentration was 10% (w / v), washed with deionized water to pH = 7.0, and dried at 37° C. to prepare super-lubricating serum albumin punctal plugs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com