High-strength and lightweight aramid paper honeycomb sandwich composite structure

A composite structure, aramid paper technology, applied in the direction of polymer adhesive additives, non-polymer adhesive additives, adhesive types, etc., can solve the problem of increasing the weight of the structure, to improve the external bearing capacity, mechanical Good performance and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

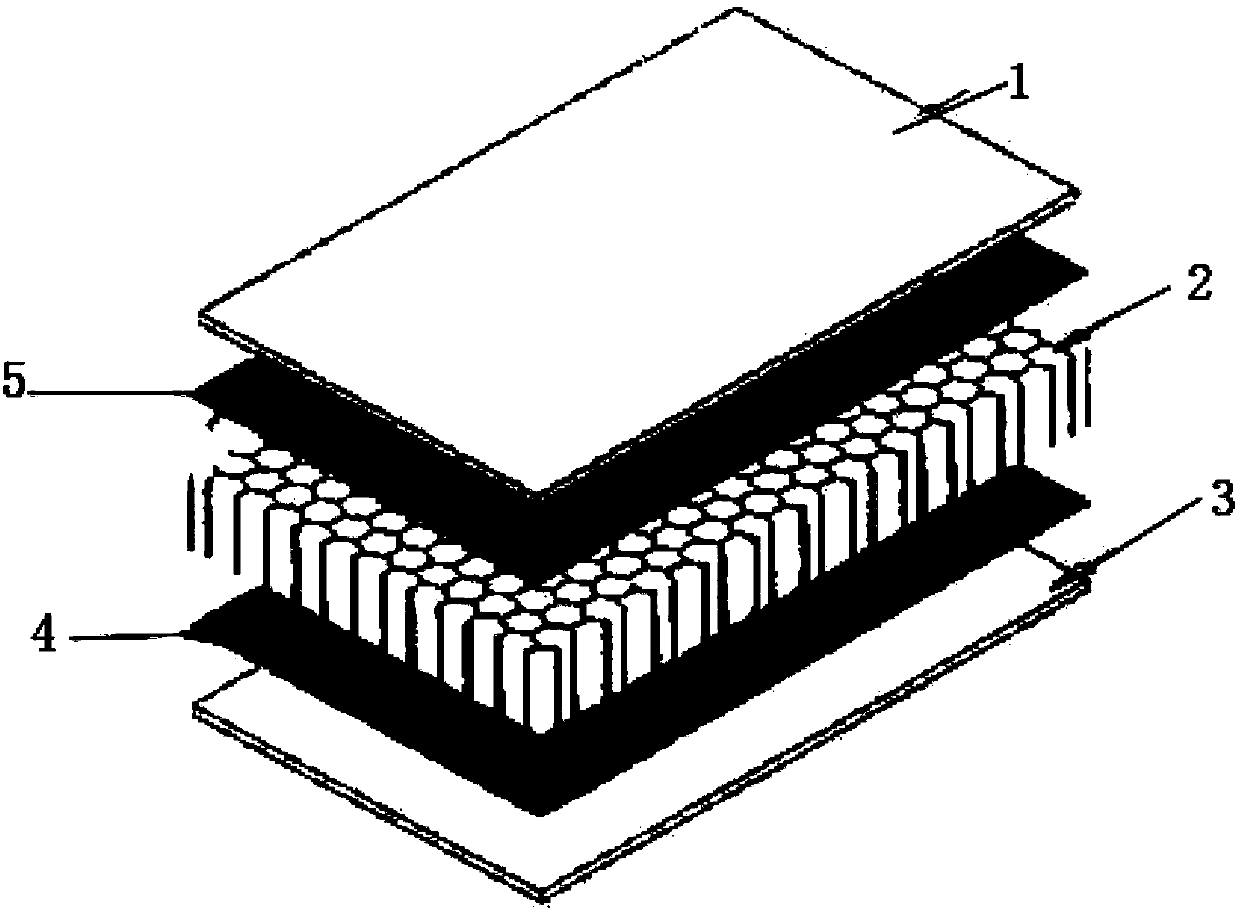

[0031]In the high-strength and light-weight aramid paper honeycomb sandwich composite structure of this embodiment, the composite board includes a lower skin 3, a lower hot-melt adhesive film 4, and an aramid paper honeycomb core stacked sequentially from bottom to top. 2. The upper hot-melt adhesive film 5 and the upper skin 1 are composited. The upper skin 1 and the lower skin 3 are glass cloth prepregs formed by impregnating glass cloth with a resin composition. The aramid paper honeycomb The cell section of the core is a regular hexagon, the radius of the circumscribed circle of the regular hexagon is 50 mm, the cell side length is 3 mm, and the aperture ratio is 1; the paper thickness of the aramid paper honeycomb core is 0.03 mm, and the density is 30 kg / m 3 ; The resin composition includes by weight: 10 parts of diphenylmethane bismaleimide, 3 parts of o-diallyl bisphenol A, 5 parts of diallyl bisphenol A, 5 parts of polyethersulfone, polyether 6 parts of ketone, 10 par...

Embodiment 2

[0040] In the high-strength and light-weight aramid paper honeycomb sandwich composite structure of this embodiment, the composite board includes a lower skin 3, a lower hot-melt adhesive film 4, and an aramid paper honeycomb core stacked sequentially from bottom to top. 2. The upper hot-melt adhesive film 5 and the upper skin 1 are composited. The upper skin 1 and the lower skin 3 are glass cloth prepregs formed by impregnating glass cloth with a resin composition. The aramid paper honeycomb The cell section of the core is a regular hexagon, the radius of the circumscribed circle of the regular hexagon is 100mm, the cell side length is 6mm, and the aperture ratio is 1; the paper thickness of the aramid paper honeycomb core is 0.06mm, and the density is 35kg / m 3 ; The resin composition comprises by weight: 20 parts of diphenylmethane bismaleimide, 8 parts of o-diallyl bisphenol A, 15 parts of diallyl bisphenol A, 10 parts of polyethersulfone, polyether 12 parts of ketone, 20 p...

Embodiment 3

[0049] In the high-strength and light-weight aramid paper honeycomb sandwich composite structure of this embodiment, the composite board includes a lower skin 3, a lower hot-melt adhesive film 4, and an aramid paper honeycomb core stacked sequentially from bottom to top. 2. The upper hot-melt adhesive film 5 and the upper skin 1 are composited. The upper skin 1 and the lower skin 3 are glass cloth prepregs formed by impregnating glass cloth with a resin composition. The aramid paper honeycomb The cell section of the core is a regular hexagon, the radius of the circumscribed circle of the regular hexagon is 50mm, the cell side length is 6mm, and the aperture ratio is 1; the paper thickness of the aramid paper honeycomb core is 0.03mm, and the density is 35kg / m 3 ; The resin composition comprises by weight: 10 parts of diphenylmethane bismaleimide phenol, 8 parts of o-diallyl bisphenol A, 5 parts of diallyl bisphenol A, 10 parts of polyethersulfone, polyether 6 parts of ketone a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com