Mesoporous carbon and preparation method thereof

A technology of mesoporous carbon and template, applied in the field of coal chemical industry, can solve the problem that mesoporous carbon with specific surface area cannot be prepared, and achieve the effect of good pore order and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

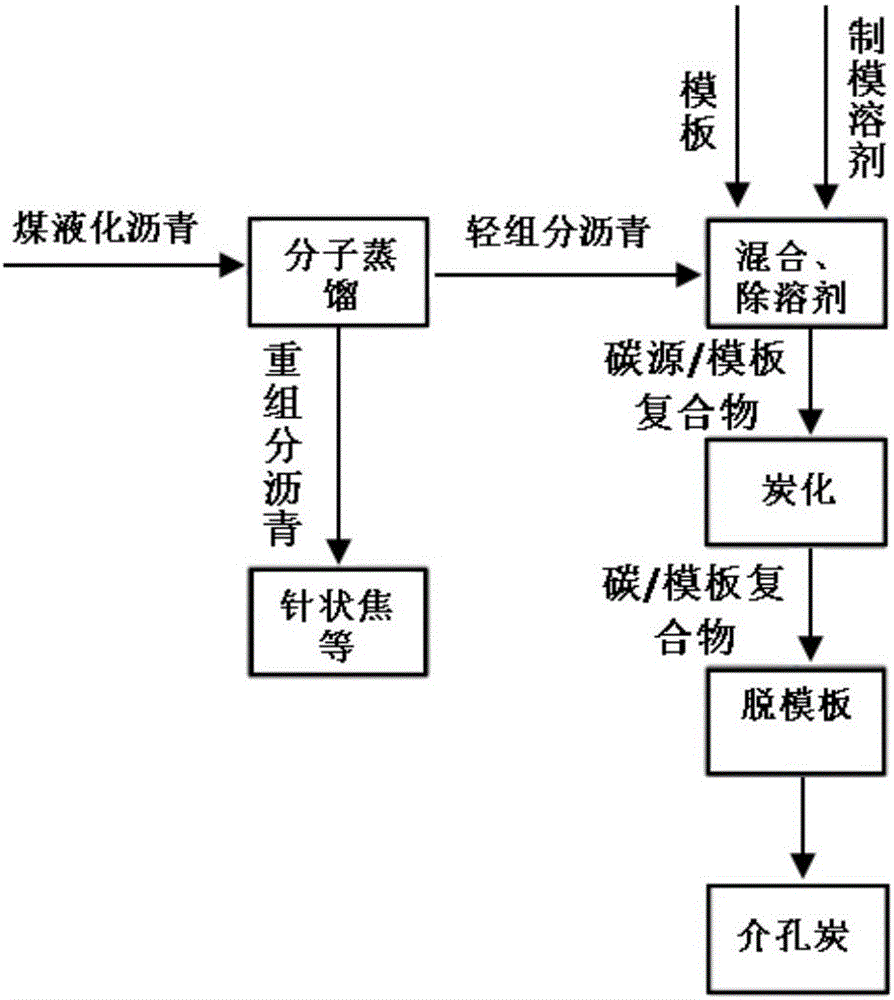

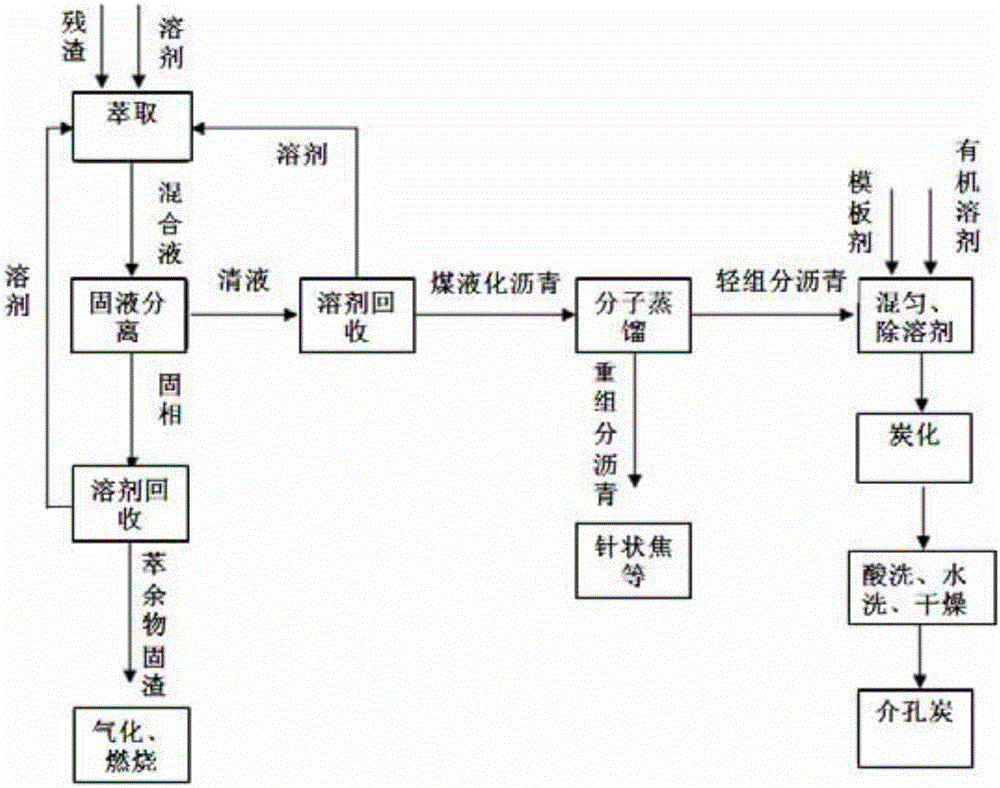

[0029] As described in the background art, there is a problem that mesoporous carbons with large specific surface area and high pore order cannot be prepared in existing methods. In order to solve the above-mentioned technical problems, the invention provides a kind of preparation method of mesoporous carbon, such as figure 1 As shown, the preparation method includes: molecular distillation process, molecular distillation of coal liquefied pitch to obtain light component pitch and heavy component pitch, the separation temperature of the molecular distillation process is 300-350 ° C, and the pressure is 15-100 Pa; Component pitch is used as carbon source to prepare mesoporous carbon.

[0030] The macromolecular compounds with condensed ring and / or aromatic ring structure in coal liquefaction bitumen are separated by molecular distillation at a specific distillation temperature and pressure, and the softening point, coking value, quinoline insolubles, etc. are lower. Light comp...

Embodiment 1

[0050] 1) Extraction process:

[0051] Add 300kg coal direct liquefaction residue and 300kg tetrahydrofuran to 2m 3 In a stirred tank, the extraction is carried out under the conditions of a pressure of 0.02MPa, a temperature of 30°C, and a stirring rate of 50r / min, and the extraction time is 30min to obtain an extraction mixture, wherein the stirred tank is protected with nitrogen. The above-mentioned extraction mixture was centrifuged in a centrifuge with a rotational speed of 7000r / min, the centrifugation temperature was 30°C, and the centrifugation time was 10min to obtain 225kg of separated solid phase and 375kg of supernatant, wherein the solid content of the supernatant was 0.001wt%.

[0052] Send all the centrifuged supernatants above into a vacuum distillation tower, recover the extraction solvent-tetrahydrofuran from the top of the tower for recycling, and collect 120 kg at the bottom of the tower with a softening point of 130°C, an ash content of 0.01wt%, quinoline ...

Embodiment 2

[0064] 1) Extraction process

[0065] Add 250kg coal direct liquefaction residue and 500kg quinoline to the 2m 3 In a stirred tank, the extraction was carried out under the conditions of a pressure of 0.01MPa, a temperature of 100°C, and a stirring rate of 80r / min, and the extraction time was 5min to obtain an extraction mixture, wherein the stirred tank was protected with nitrogen. The above-mentioned extraction mixture was subjected to solid-liquid separation in a primary cyclone separator to obtain 141kg of primary separation solid phase and 609kg of primary separation clear liquid, wherein the centrifugation temperature was 100°C, and the inlet pressure of the primary cyclone separator was 0.2MPa ,;

[0066] The above-mentioned first-level clear liquid is sent to the second-level centrifuge for solid-liquid separation, and 51kg of second-level separation solid phase and 558kg of second-level clear liquid are obtained, wherein the centrifugal temperature is 100°C, the pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com