Glass wool and preparation method thereof

A glass wool, mass ratio technology, applied in the field of glass wool, can solve the problems of poor mechanical properties and thermal insulation, poor water resistance of glass wool, etc., and achieve the effect of good energy storage, regular molecular structure, and increased thermal energy absorption efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

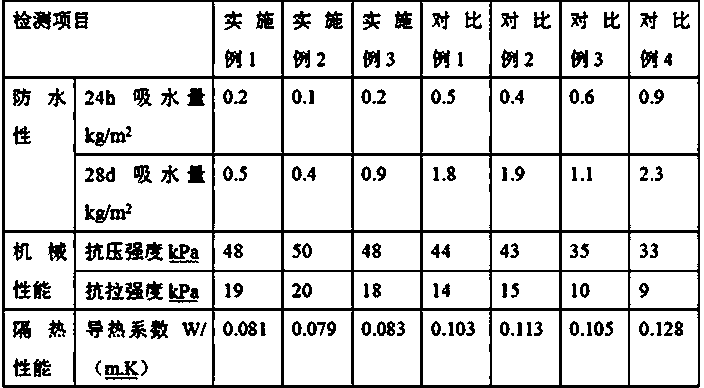

Examples

preparation example Construction

[0024] The preparation method of thermal insulation additive is:

[0025] (1) Take hydrochloric acid with a mass fraction of 35% and place it in a closed container, and volatilize it to obtain hydrogen chloride gas. Put graphene oxide in the hydrogen chloride gas and let it stand at 25~30°C for 4~7h. 1~5:2~6, add hydriodic acid aqueous solution with a mass fraction of 10%, let it stand for 10~15h, filter, take the filter cake and add it to absolute ethanol according to the mass ratio of 2~5:10~20, stir and mix for 3~ 8 days, dry, then pass through argon protection, anneal at 500~600°C for 1~3h, cool to room temperature, ball mill for 5~10min, and get the ball milled product;

[0026] (2) Take Tris-HCl buffer solution with pH 8.5 and mix it with absolute ethanol at a mass ratio of 3~6:1~3 to obtain a mixed solution. Take dopamine hydrochloride at a mass ratio of 3~6:1~3:20 Add dodecanethiol and mixed solution at ~30°C, stir and mix for 30~50min at 30~35°C to obtain the stirred...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com