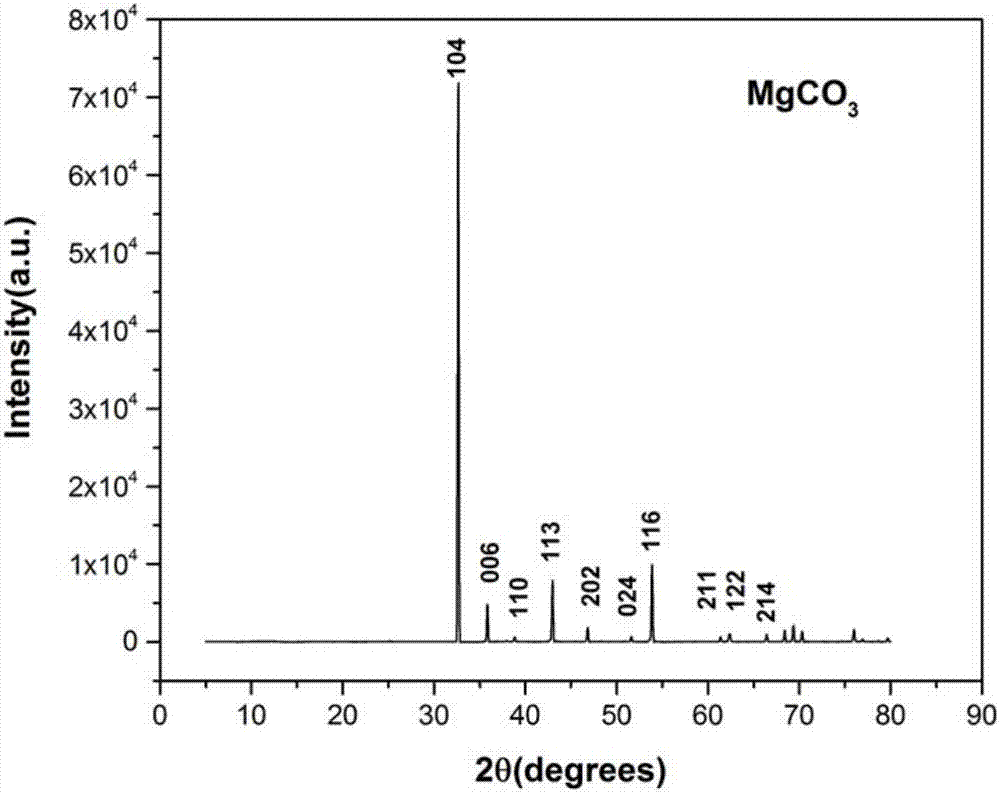

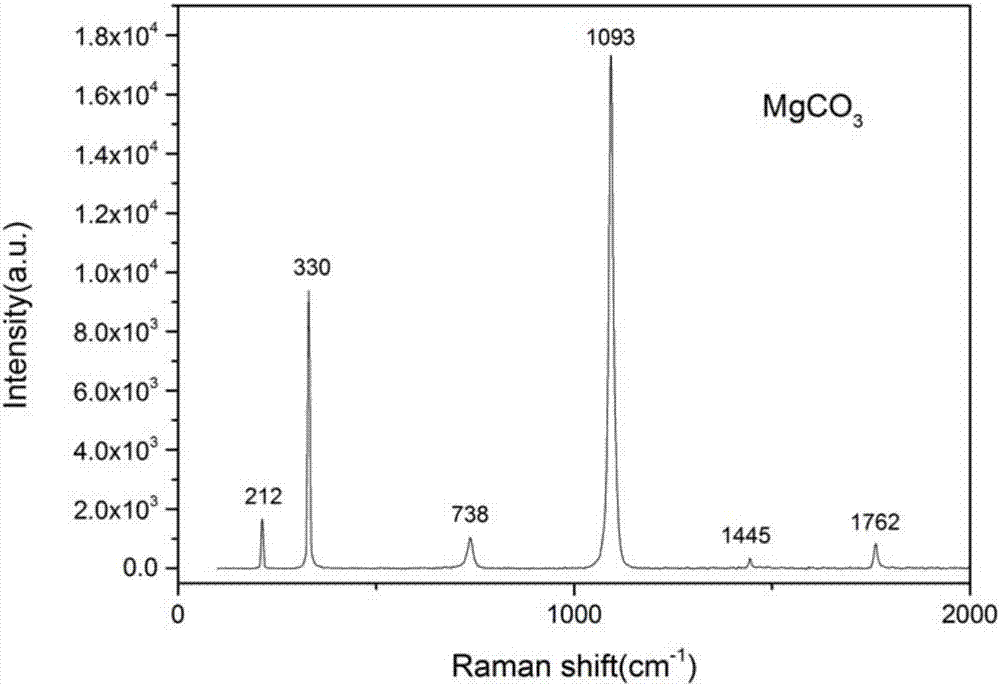

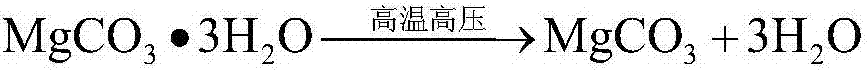

A kind of method for preparing anhydrous magnesium carbonate under high temperature and high pressure

Anhydrous magnesium carbonate, high temperature and high pressure technology, applied in the direction of magnesium carbonate, etc., can solve the problems of low purity of magnesium carbonate, poor chemical stability, complicated operation process, etc., achieve chemical stability, not easy to absorb water, short reaction time, The effect of simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Using analytically pure magnesium carbonate trihydrate as the starting material, powder magnesium carbonate trihydrate (about 0.30g) was pressed into a cylinder (Φ6mm×5mm) using a powder tablet press, and wrapped with silver foil (0.025mm) to make Form the sample; use NaCl as the pressure transmission medium, and use a powder tablet press to press the sample into the NaCl salt column (Φ10mm×12mm) to complete the high-pressure assembly block. High voltage assembly block assembly method:

[0056] ① A circular through hole with a diameter of 14mm is drilled in the center of a 32×32mm pyrophyllite block;

[0057] ② A graphite heating furnace with an outer diameter of 14mm and an inner diameter of 10mm is placed inside the circular through hole of the pyrophyllite block;

[0058] ③ A sodium chloride cylinder containing a magnesium carbonate trihydrate cylinder is placed in the middle of the graphite heating furnace, and the upper and lower sides are blocked with pyrophyllit...

Embodiment 2

[0062] Using analytically pure magnesium carbonate trihydrate as the starting material, powder magnesium carbonate trihydrate (about 0.30g) was pressed into a cylinder (Φ6mm×5mm) using a powder tablet press, and wrapped with silver foil (0.025mm) to make Form the sample; use NaCl as the pressure transmission medium, and use a powder tablet press to press the sample into the NaCl salt column (Φ10mm×12mm) to complete the high-pressure assembly block. High voltage assembly block assembly method:

[0063] ① A circular through hole with a diameter of 14mm is drilled in the center of a 32×32mm pyrophyllite block;

[0064] ②A graphite heating furnace with an outer diameter of 14mm and an inner diameter of 10mm is placed inside the circular through hole of the pyrophyllite block;

[0065] ③ A sodium chloride cylinder containing a magnesium carbonate trihydrate cylinder is placed in the middle of the graphite heating furnace, and the top and bottom are blocked with pyrophyllite plugs ...

Embodiment 3

[0069] Using analytically pure magnesium carbonate trihydrate as the starting material, powder magnesium carbonate trihydrate (about 0.30g) was pressed into a cylinder (Φ6mm×5mm) using a powder tablet press, and wrapped with silver foil (0.025mm) to make Form the sample; use NaCl as the pressure transmission medium, and use a powder tablet press to press the sample into the NaCl salt column (Φ10mm×12mm) to complete the high-pressure assembly block. High voltage assembly block assembly method:

[0070] ① A circular through hole with a diameter of 14mm is drilled in the center of a 32×32mm pyrophyllite block;

[0071] ②A graphite heating furnace with an outer diameter of 14mm and an inner diameter of 10mm is placed inside the circular through hole of the pyrophyllite block;

[0072] ③ A sodium chloride cylinder containing a magnesium carbonate trihydrate cylinder is placed in the middle of the graphite heating furnace, and the top and bottom are blocked with pyrophyllite plugs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com