Method for high temperature and high pressure production of sodium methoxide and device thereof

A high temperature and high pressure, sodium methoxide technology, applied in the preparation of alcohol metal, sustainable manufacturing/processing, chemical industry, etc., can solve the problems of high energy consumption, no industrial value, slow reaction speed, etc., and reduce the consumption of circulating water , reduce the labor intensity of workers, and eliminate the effect of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

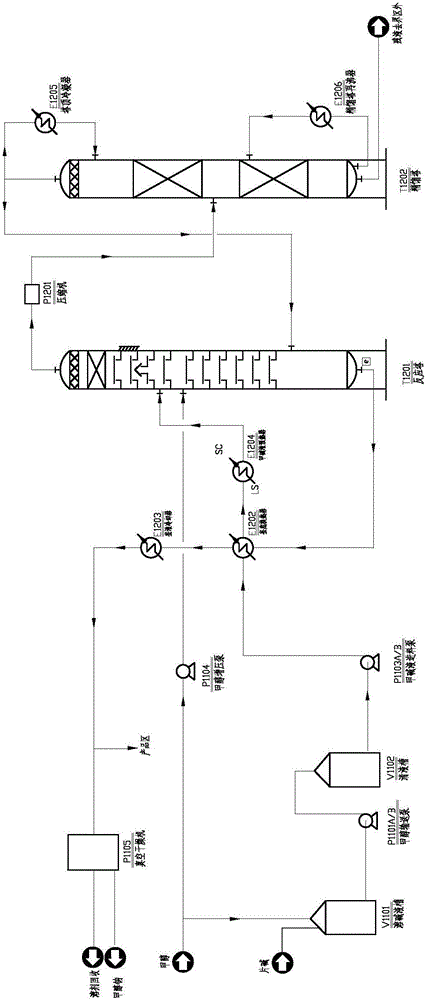

Image

Examples

Embodiment 1

[0035] Methanol and caustic soda from the outside enter the alkali-dissolving tank V1101, control the temperature of the alkali-dissolving solution below 75°C to completely dissolve NaOH to supersaturation, and send the solution to the clear liquid tank V1102 through the methanol delivery pump P1101A / B.

[0036] The lye in the clear liquid tank V1102 is transported to the heat exchanger E1202 at the bottom of the reaction tower through the lye feed pump P1103A / B, and is preheated by the lye preheater E1204 after exchanging heat with the liquid phase at the bottom of the reaction tower T1201 After reaching 140°C, it enters from the upper part of the reaction tower T1201, and the feeding speed of the caustic soda is 4-6m 3 / h, the mass concentration of the alkali is 20.5%, the anhydrous methanol vapor from the methanol rectification tower T1202 enters from the bottom of the reaction tower T1201, and the flow rate of the anhydrous methanol vapor is 12000~16000Nm 3 / h, the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com