Bipolar OLED (organic light-emitting diode) phosphorescence main body material and luminescent device containing material

A light-emitting device and light-emitting layer technology, applied in the field of OLED materials and light-emitting devices, can solve the problems of triplet-triplet annihilation acceleration, rapid decline in device efficiency, etc., to reduce phosphorescence quenching, increase glass transition temperature and thermal decomposition The effect of high temperature and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

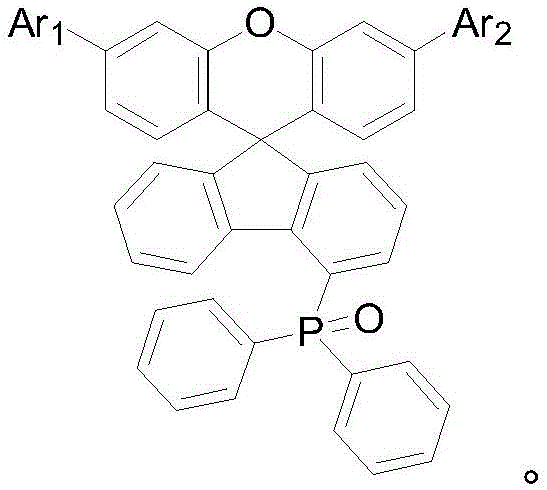

[0033] Embodiment 1 The preparation of compound C02

[0034]

[0035] 1) Under nitrogen protection, the raw material 3,6-dibromoxanthone (1.77g, 5mmol), phenoxazine (2.02g, 11mmol) and 150mL toluene were added to a 250mL three-necked flask, and then the catalyst palladium acetate ( 0.022g, 0.1mmol) and catalyst ligand tri-tert-butylphosphine tetrafluoroborate (0.058g, 0.2mmol), acid-binding agent potassium carbonate (2.07g, 15mmol). The system was heated to reflux and stirred for 10 hours, then cooled naturally to 20-25°C, then 50 mL of water was added to quench the reaction, the liquid was separated, the solvent was removed, and the crude product was crystallized with toluene to obtain 2.23 g of intermediate C02-a with a yield of 79.9%.

[0036] High resolution mass spectrometry, ESI source, positive ion mode, molecular formula C 37 h 22 N 2 o 4 , the theoretical value is 558.1580, and the test value is 558.1576. Elemental analysis (C 37 h 22 N 2 o 4 ), theoretica...

Embodiment 2

[0041] The preparation of embodiment 2 compound C03

[0042]

[0043] The synthesis method refers to the preparation method of C02, and the total yield is 26.5%.

[0044] High resolution mass spectrometry, ESI source, positive ion mode, molecular formula C 67 h 51 N 2 o 2 P, theoretical value 946.3688, test value 946.3683. Elemental analysis (C 67 h 51 N 2 o 2 P), theoretical value C: 84.97, H: 5.43, N: 2.96, O: 3.38, P: 3.27, measured value C: 84.96, H: 5.44, N: 2.96, O: 3.36, P: 3.29.

Embodiment 3

[0045] The preparation of embodiment 3 compound C04

[0046]

[0047] The synthesis method refers to the preparation method of C02, and the total yield is 23.6%.

[0048] High resolution mass spectrometry, ESI source, positive ion mode, molecular formula C 61 h 39 N 2 o 2 P, theoretical value 862.2749, test value 862.2751. Elemental analysis (C 61 h 39 N 2 o 2 P), theoretical value C: 84.90, H: 4.56, N: 3.25, O: 3.71, P: 3.59, measured value C: 84.91, H: 4.57, N: 3.25, O: 3.71, P: 3.59.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum current efficiency | aaaaa | aaaaa |

| Maximum current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com