A kind of preparation method of modified hydroxypropyl guar gum thickener

A technology of hydroxypropyl guar gum and thickening agent, applied in chemical instruments and methods, drilling compositions and other directions, can solve the problems of inability to meet high temperature and deep wells, low equipment utilization, affecting gelling performance, etc., and achieves good performance. The effect of shear resistance and sand carrying performance, high equipment utilization and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

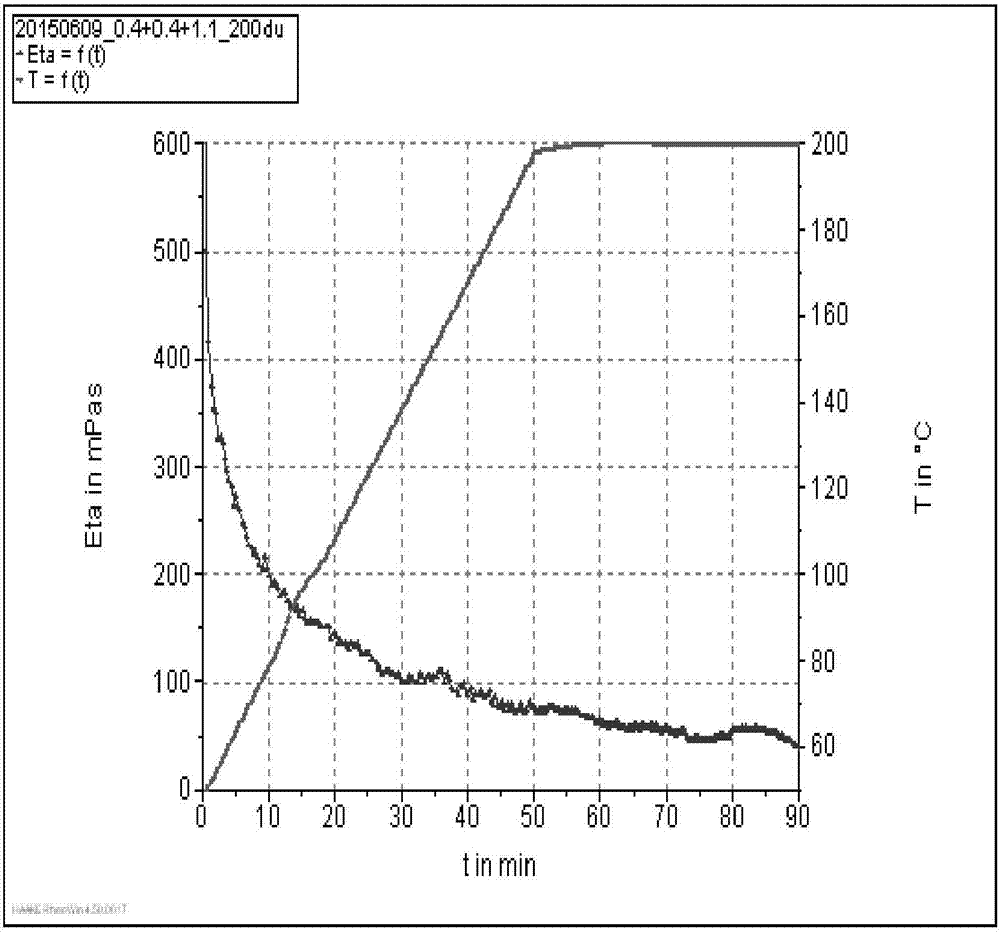

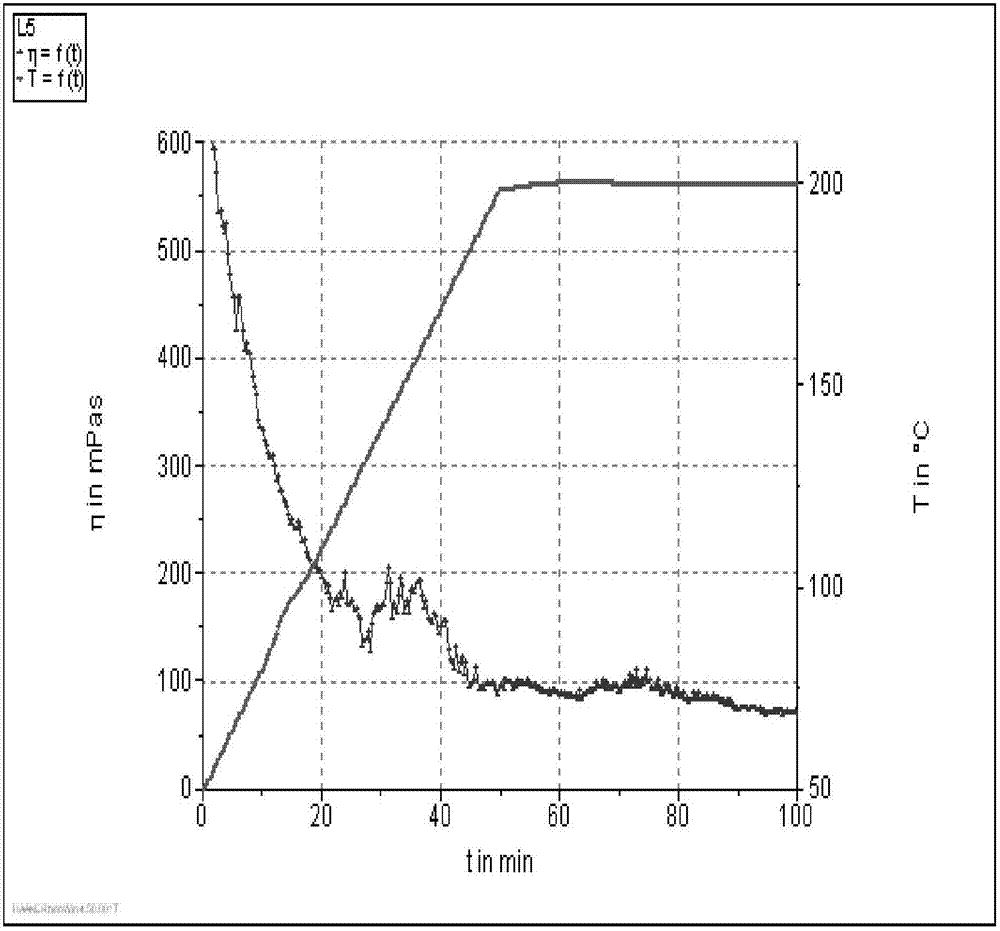

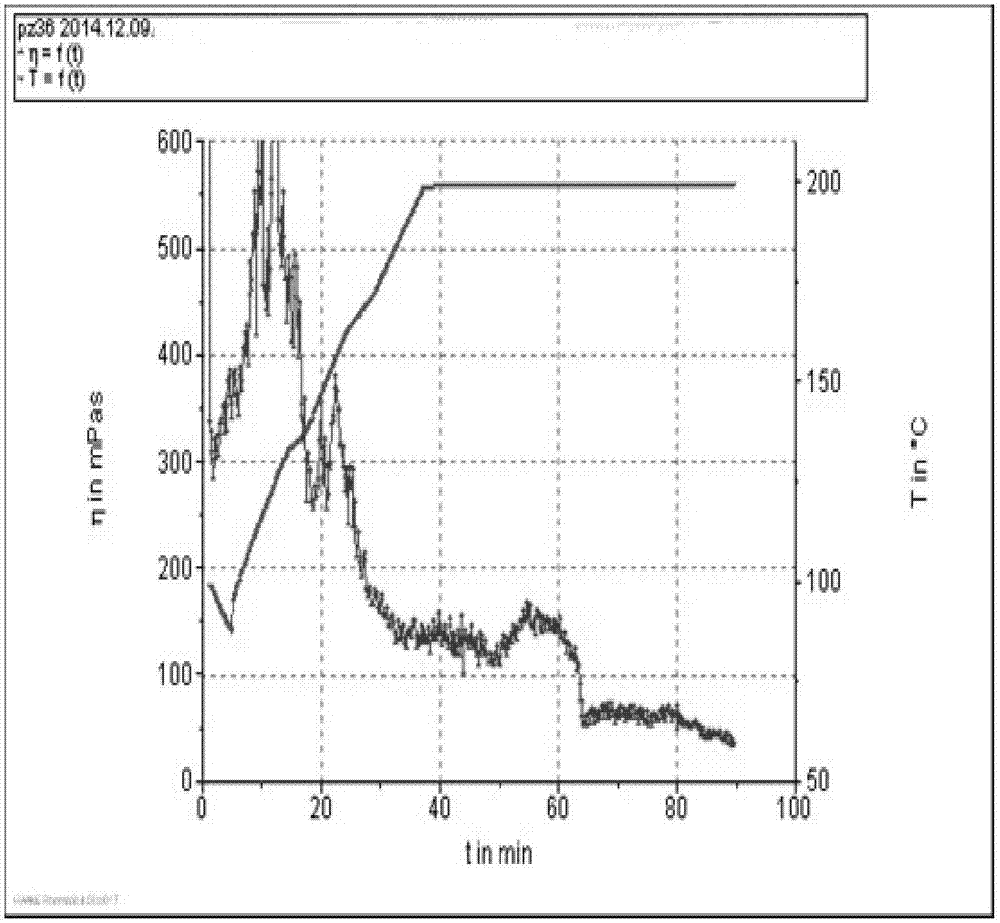

Image

Examples

Embodiment 1

[0028] A kind of preparation method of modified hydroxypropyl guar gum thickener, comprises the steps:

[0029] Step (1): Dissolve 15g hydroxypropyl guar gum in 10 times of absolute ethanol, stir, then add 7g 2-pyrrolidone and 1.8g sodium hydroxide, stir and dissolve for 0.5h,

[0030] Step (2): Add 8g of sodium 2-chloroethylsulfonate, stir and react at 45°C for 10h to fully react;

[0031] Step (3): Cool to room temperature, filter, wash the filter cake three times with absolute ethanol, dry at 80°C, and dry for 3.5 hours, volatilize all the absolute ethanol in this step and step (1), and grind to obtain powder to obtain the light yellow thickener.

Embodiment 2

[0033] A kind of preparation method of modified hydroxypropyl guar gum thickener, comprises the steps:

[0034] Step (1): Dissolve 18g hydroxypropyl guar gum in 15 times of absolute ethanol, stir, then add 5g 2-pyrrolidone and 2.4g sodium hydroxide, stir and dissolve for 1h,

[0035] Step (2): Add 7g of sodium 2-chloroethylsulfonate, stir and react at 60°C for 12h to fully react;

[0036] Step (3): Cool to room temperature, filter, wash the filter cake three times with absolute ethanol, dry at 85°C, and dry for 2.5 hours, volatilize all the absolute ethanol in this step and step (1), and grind to obtain powder to obtain the light yellow thickener.

Embodiment 3

[0038] A kind of preparation method of modified hydroxypropyl guar gum thickener, comprises the steps:

[0039] Step (1): Dissolve 19g hydroxypropyl guar gum in 20 times of absolute ethanol, stir, then add 5g 2-pyrrolidone and 2.7g sodium hydroxide, stir and dissolve for 0.5h,

[0040] Step (2): Add 6g of sodium 2-chloroethylsulfonate, stir and react at 50°C for 15h to fully react;

[0041] Step (3): Cool to room temperature, filter, wash the filter cake three times with absolute ethanol, dry the temperature at 90°C, and dry for 1.5 hours, volatilize all the absolute ethanol in this step and step (1), and grind to obtain powder to obtain the light yellow thickener.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com