Medium-high temperature retarder for oil well cement and preparation method thereof

A technology of oil well cement and retarder, which is applied in the field of oil drilling, well completion or well cementing, and can solve the problems of ineffective retarding effect, unsatisfactory use effect of medium-temperature and high-temperature retarders, and the latter prone to over-retarding Problems such as coagulation, etc., to achieve the effect of simple and feasible preparation method, low cost, mild and controllable conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

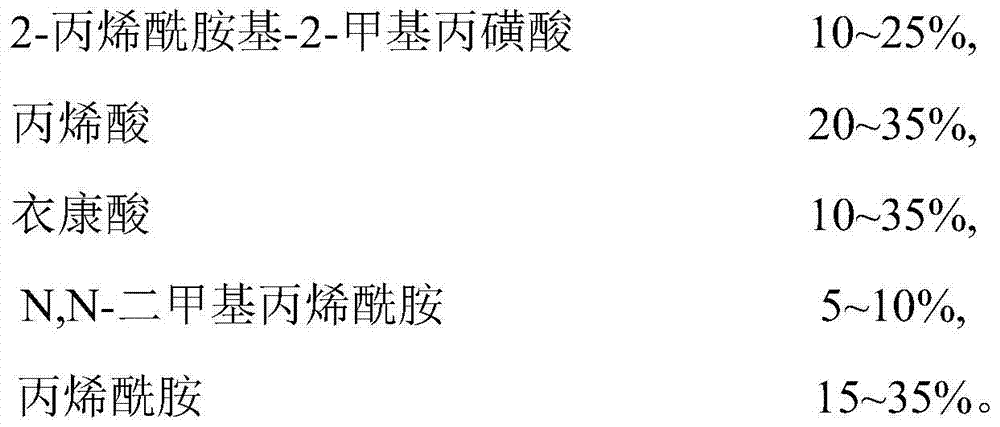

Method used

Image

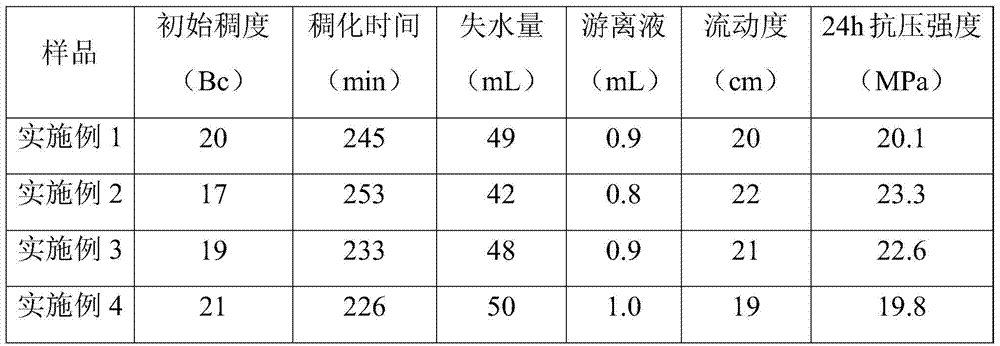

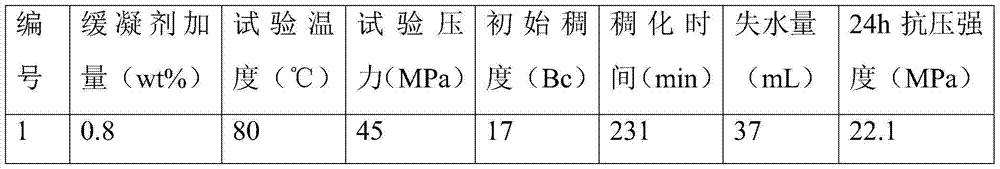

Examples

Embodiment 1

[0017] 1.5g 2-acrylamido-2-methylpropanesulfonic acid, 2.5g acrylic acid, 1.5g itaconic acid, 0.5g N,N-dimethylacrylamide and 3.0g acrylamide were dissolved in relative to the total mass of the monomer 2 times the amount of water, adjust the pH to 6 with 10 wt% sodium hydroxide aqueous solution, protect with nitrogen, add 0.1 g of ammonium persulfate, react at 60°C for 4 hours, and cool to room temperature to obtain a colorless viscous liquid.

Embodiment 2

[0019] 2.0g 2-acrylamido-2-methylpropanesulfonic acid, 3.0g acrylic acid, 2.0g itaconic acid, 0.5g N,N-dimethylacrylamide and 1.5g acrylamide were dissolved in relative to the total mass of the monomer 2 times the amount of water, adjust the pH to 6 with 10wt% aqueous sodium hydroxide solution, under nitrogen protection, add 0.15 g of ammonium persulfate, react at 70°C for 5 hours, and cool to room temperature to obtain a colorless viscous liquid.

Embodiment 3

[0021] 1.5g 2-acrylamido-2-methylpropanesulfonic acid, 2.0g acrylic acid, 3.0g itaconic acid, 0.5g N,N-dimethylacrylamide and 2.0g acrylamide were dissolved in relative to the total mass of the monomer 3 times the amount of water, adjust the pH to 5 with 10 wt% sodium hydroxide aqueous solution, protect with nitrogen, add 0.2 g of ammonium persulfate, react at 80°C for 6 hours, and cool to room temperature to obtain a colorless viscous liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com