A double-sided plexus structure anti-temperature and anti-salt oil well cement fluid loss reducer and its preparation method

A fluid loss reducing agent and oil well cement technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of cementing operation failure, cement slurry dehydration, poor cementing quality, etc., and achieve good compatibility , reduce water loss, reasonable price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] A method for preparing a double-sided plexus structure anti-temperature and anti-salt oil well cement fluid loss reducing agent, comprising the following steps:

[0040] (1) Weigh 41.44g of 2-acrylamide-2-methylpropanesulfonic acid (AMPS), 7.11g of acrylamide (AM), 7.21g of acrylic acid (AA), 0.0558g of graphene, and 258g of water;

[0041] (2) Water is added to the reaction kettle, then graphene is added, and stirred at a high speed for 30min, so that the graphene is uniformly dispersed in water to obtain a graphene dispersion;

[0042] (3) Add all AMPS, AA, and AM to the reaction kettle, and stir at high speed for 30 minutes; slowly add 11.0g-12.0g NaOH to the uniformly mixed reaction solution, and adjust the pH of the solution to 7.0-8.0;

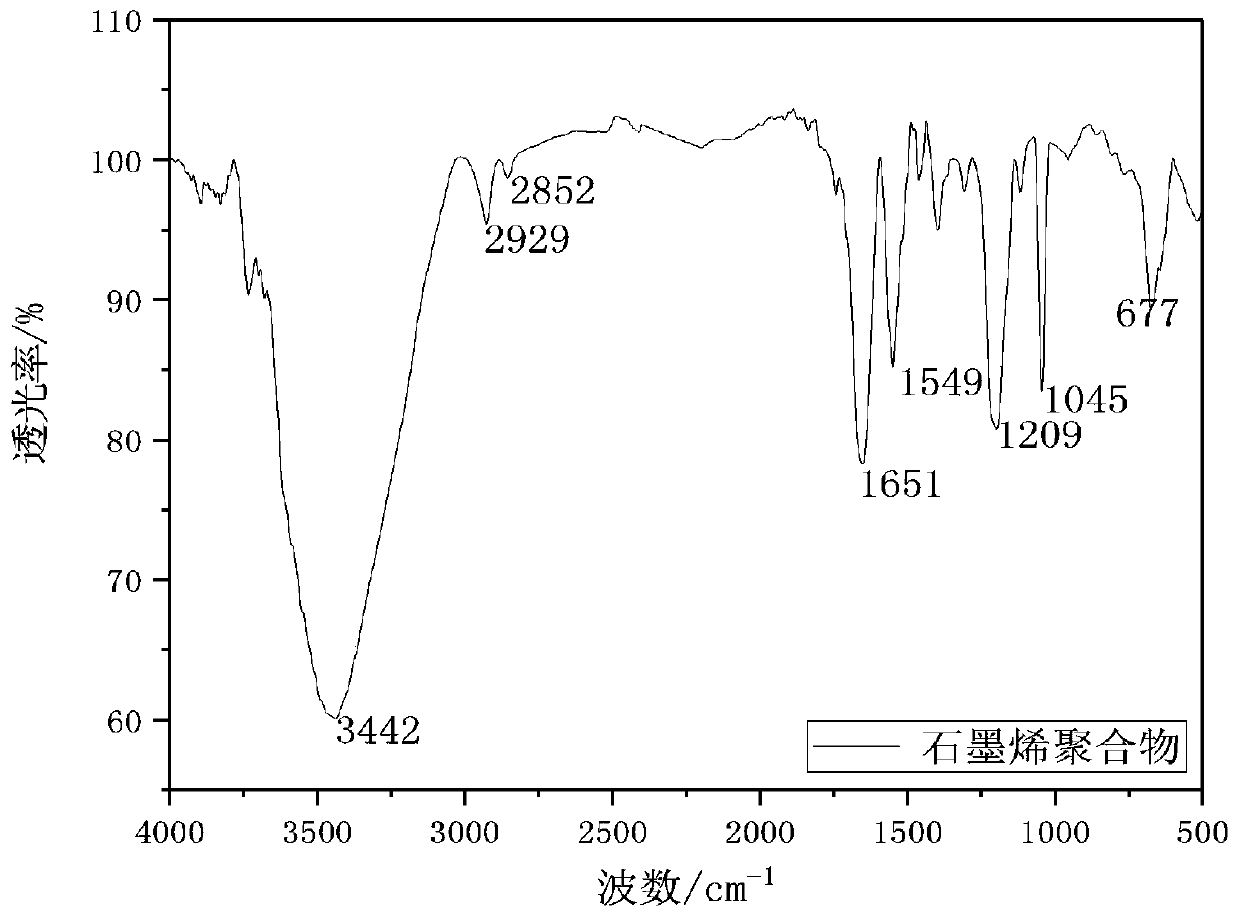

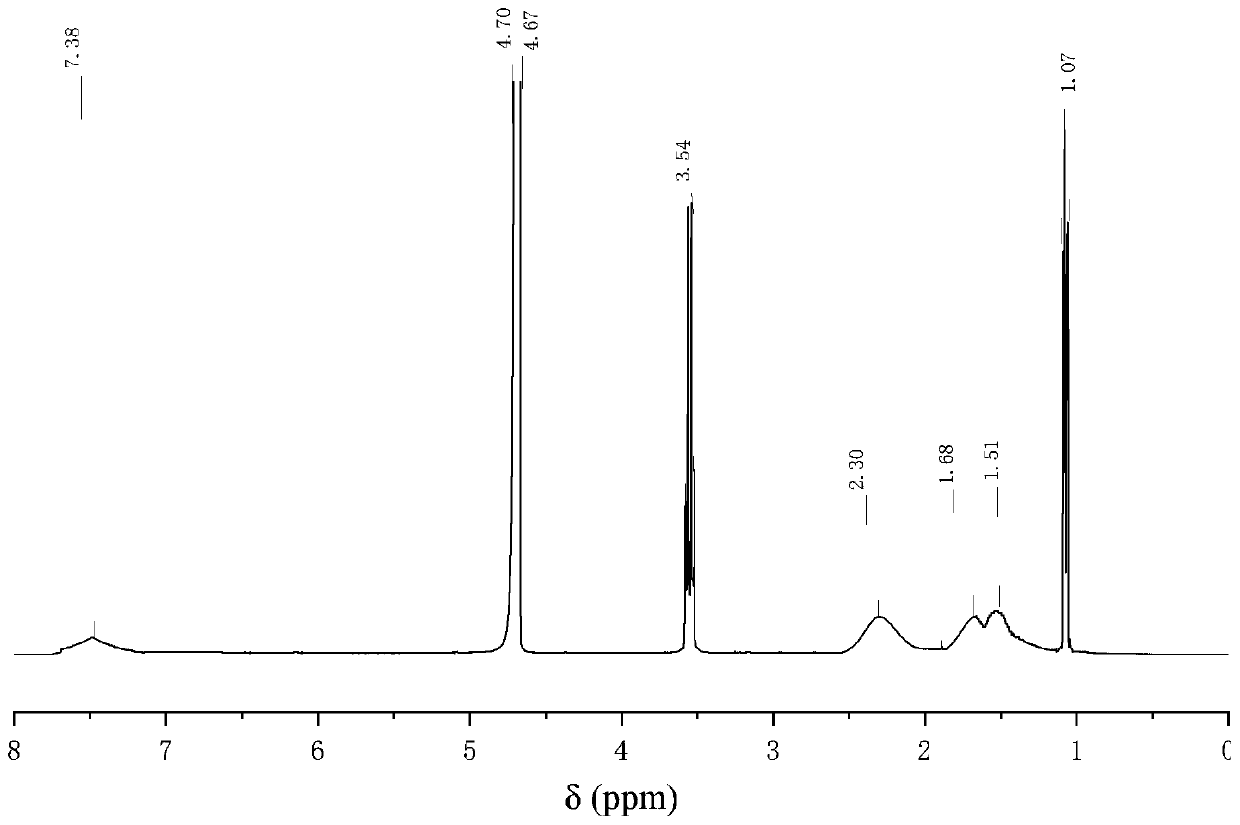

[0043] (4) Raise the temperature of the reaction solution to 80°C, pass nitrogen gas into the reaction kettle for 15 minutes to remove oxygen at a ventilation speed of 3L / min~5L / min, then add 0.2230g of ammonium persulfate, react ...

experiment approach 1

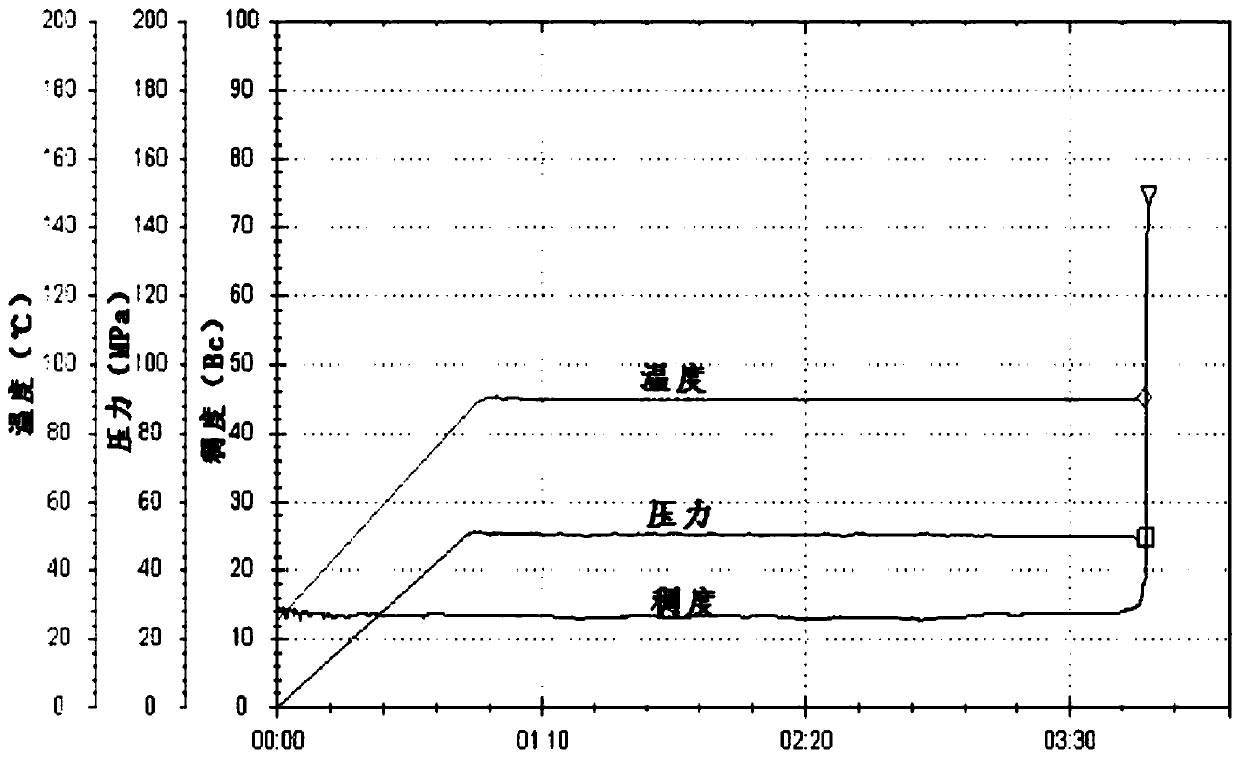

[0054] Experimental scheme 1: Experimental temperature, 90°C; experimental cement slurry formula: 600g Jiahua G grade oil well cement + 0.3% oil well cement drag reducer SXY + 3%-4% fluid loss reducer solution + 0.3% ~ 1.0% oil well Cement retarder BS200R (medium temperature) + water (W / C=0.44).

experiment approach 2

[0055] Experimental scheme 2: Experimental temperature, 150°C and 200°C; the experimental cement slurry formula is: 600g Jiahua G grade oil well cement + 240g quartz sand + 0.3% oil well cement drag reducer SXY + 4%-6% fluid loss reducer solution + 3% ~ 8% oil well cement retarder BS200G (high temperature) + water (W / S=0.42).

[0056] The traditional similar linear fluid loss reducer BS100L (produced by Sichuan Hongsheng Petroleum Engineering Technology Service Co., Ltd.) was selected as a comparison sample, and the experimental test was carried out under the same conditions. The experimental results are shown in Table 1.

[0057] Table 1. Temperature resistance test results of fluid loss reducer of the present invention and traditional fluid loss reducer

[0058]

[0059] The experimental results in Table 1 show that the fluid loss reducer prepared by the present invention can be used at a temperature ranging from 90°C to 200°C (circulation temperature); the API loss of c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com