Polyvinylidene difluoride-based thermoplastic vulcanized rubber and preparation method thereof

A polyvinylidene fluoride and thermoplastic vulcanization technology, applied in the field of polymer materials, can solve the problems of complex preparation process, high melt viscosity, unfavorable processing, etc., and achieve high strength, excellent thermoplastic performance, and good resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

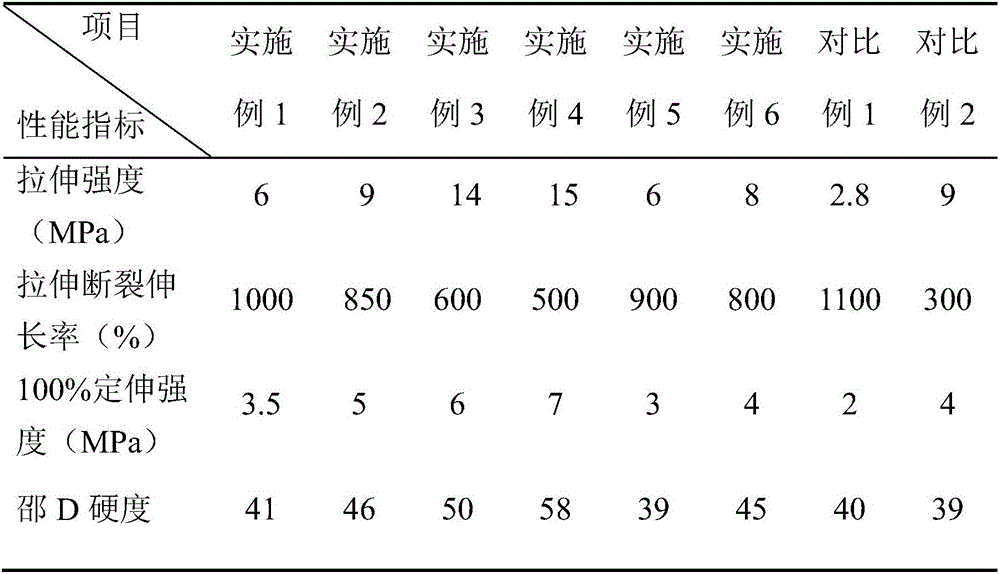

[0020] Ethylene-butyl acrylate-glycidyl methacrylate copolymer rubber 450g, polyvinylidene fluoride 150g, 2,2,6,6-tetramethylpiperidine-nitrogen-oxide 2.5g, 2,2,4 - 2.5 g of trimethyl-1,2-dihydroquinoline polymer was mixed with an internal mixer for 10 minutes to obtain a rubber compound (blending conditions: the temperature was 190 ° C, the rotor speed was 80 rpm), and then mixed Glue and amine vulcanizing agent 2.5g, dibutyl sebacate 15g, 1010 antioxidant 2.5g and 168 antioxidant 0.5g obtain thermoplastic vulcanized rubber (blending condition: temperature is 190 °C, the rotor speed is 80 rpm). The thermoplastic vulcanizate was formed by hot pressing with a flat vulcanizer to obtain a 1 mm thick sheet of thermoplastic vulcanizate, which was cut into standard specimens for mechanical property testing according to relevant standards. The test results are listed in Table 1.

Embodiment 2

[0022] Ethylene-butyl acrylate-glycidyl methacrylate copolymer rubber 450g, polyvinylidene fluoride 150g, 2,2,6,6-tetramethylpiperidine-nitrogen-oxide 2.5g, 2,2,4 - 2.5 g of trimethyl-1,2-dihydroquinoline polymer was mixed with an internal mixer for 10 minutes to obtain a rubber compound (blending conditions: the temperature was 190 ° C, the rotor speed was 80 rpm), and then mixed Glue and amine vulcanizing agent 5g, dibutyl sebacate 15g, 1010 antioxidant 2.5g and 168 antioxidant 0.5g melt blending 10min to obtain thermoplastic vulcanizate in internal mixer (blending condition: temperature is 190 ℃ , the rotor speed is 80 rpm). The thermoplastic vulcanizate was formed by hot pressing with a flat vulcanizer to obtain a 1 mm thick sheet of thermoplastic vulcanizate, which was cut into standard specimens for mechanical property testing according to relevant standards. The test results are listed in Table 1.

Embodiment 3

[0024] Ethylene-butyl acrylate-glycidyl methacrylate copolymer rubber 450g, polyvinylidene fluoride 150g, 2,2,6,6-tetramethylpiperidine-nitrogen-oxide 2.5g, 2,2,4 - 2.5 g of trimethyl-1,2-dihydroquinoline polymer was mixed with an internal mixer for 10 minutes to obtain a rubber compound (blending conditions: the temperature was 190 ° C, the rotor speed was 80 rpm), and then mixed Glue and amine vulcanizing agent 7.5g, dibutyl sebacate 15g, 1010 antioxidant 2.5g and 168 antioxidant 0.5g obtain thermoplastic vulcanized rubber (blending condition: temperature is 190 °C, the rotor speed is 80 rpm). The thermoplastic vulcanizate was formed by hot pressing with a flat vulcanizer to obtain a 1 mm thick sheet of thermoplastic vulcanizate, which was cut into standard specimens for mechanical property testing according to relevant standards. The test results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com