Preparing method of polyhedral oligomeric silsesquioxane modified carbon nano tubes and application

A technology of silsesquioxane and nanotubes, which is applied in the field of carbon nanotube modification, can solve problems that affect researchers' research enthusiasm, achieve improved dispersion and interface bonding performance, improve dispersion and interface bonding, and improve mechanical properties. Effects of performance and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In this example, the carboxylated carbon nanotubes used were purchased from the Chengdu Institute of Organic Chemistry, Chinese Academy of Sciences, and the aminated cage silsesquioxane used was purchased from Hybrid Plastics in the United States;

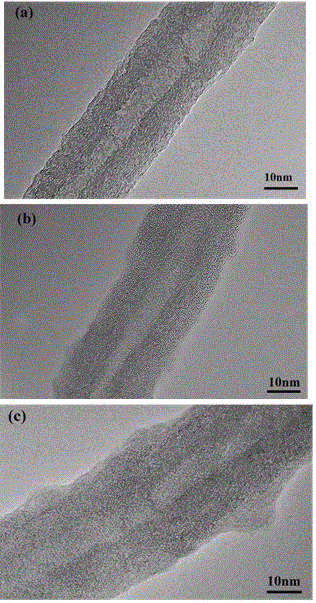

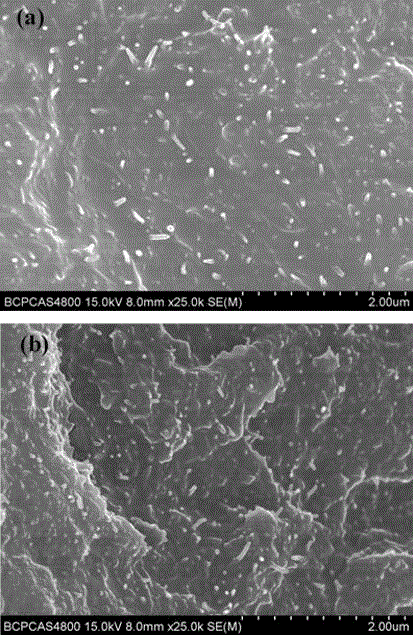

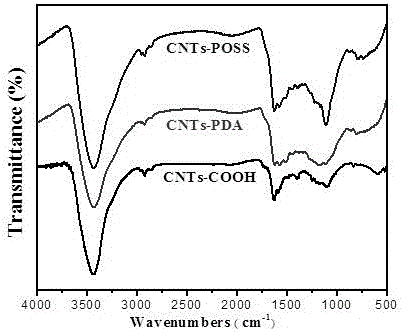

[0036] Step Ⅰ: put the purchased carboxylated carbon nanotubes into a sieving machine to obtain carboxylated carbon nanotubes with a uniform particle size of 100 mesh, use an ethanol water bath to sonicate for 1 to 2 hours, and dry to obtain uniform particle size and fluffy state Carbon nanotubes, named: fluffy carboxylated carbon nanotubes;

[0037] Step Ⅱ: Add Tris buffer solution with a pH of 8.5 to the fluffy carboxylated carbon nanotubes to prepare a mixed solution Ⅰ with a carboxylated carbon nanotube content of 0.5g / 100ml, and ultrasonically treat it under the condition of 60W-120W for 5 minutes;

[0038] Step III: Add dopamine hydrochloride into mixed solution I, use mixed solution I to prepare mixed solution II with...

Embodiment 2

[0053] In this example, the carboxylated carbon nanotubes used were purchased from the Chengdu Institute of Organic Chemistry, Chinese Academy of Sciences, and the aminated cage silsesquioxane used was purchased from Hybrid Plastics in the United States;

[0054] Step Ⅰ: put the purchased carboxylated carbon nanotubes into a sieving machine to obtain carboxylated carbon nanotubes with a uniform particle size of 200 meshes, and use an ethanol water bath to ultrasonicate for 1.5 hours and dry to obtain carbon with uniform particle size and fluffy state Nanotubes, named: fluffy carboxylated carbon nanotubes;

[0055] Step Ⅱ: add Tris buffer solution with a pH of 8.5 to the fluffy carboxylated carbon nanotubes to prepare a mixed solution Ⅰ with a carboxylated carbon nanotube content of 1.0 g / 100ml, and ultrasonically treat it under the condition of 60W-120W for 5 minutes;

[0056] Step III: Add dopamine hydrochloride into mixed solution I, use mixed solution I to prepare mixed sol...

Embodiment 3

[0063] In this example, the carboxylated carbon nanotubes used were purchased from the Chengdu Institute of Organic Chemistry, Chinese Academy of Sciences, and the aminated cage silsesquioxane used was purchased from Hybrid Plastics in the United States;

[0064] Step Ⅰ: Put the purchased carboxylated carbon nanotubes into a sieving machine to obtain carboxylated carbon nanotubes with a uniform particle size of 300 meshes, and use an ethanol water bath to ultrasonicate for 2 hours and dry to obtain carbon with uniform particle size and fluffy state. Nanotubes, named: fluffy carboxylated carbon nanotubes;

[0065] Step Ⅱ: add Tris buffer solution with a pH of 8.6 to the fluffy carboxylated carbon nanotubes to prepare a mixed solution Ⅰ with a carboxylated carbon nanotube content of 0.1 g / 100ml, and ultrasonically treat it at 120W for 5 minutes;

[0066] Step III: Add dopamine hydrochloride into mixed solution I, use mixed solution I to prepare mixed solution II with a final con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com