Rebar cleaning method

A technology for steel bars and anodes, applied in the field of steel bar cleaning, can solve the problems of acid pollution and health damage of operators, and achieve the effects of low cost, convenient operation and less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Washing treatment in a sodium carbonate solution with a mass fraction of 15% for 120 seconds to remove the scale of the corrosion-resistant steel bar.

[0015] 1. Prepare a sodium carbonate solution with a mass fraction of 15%, pour it into the cleaning tank, and the volume of the solution exceeds two-thirds of the cleaning tank;

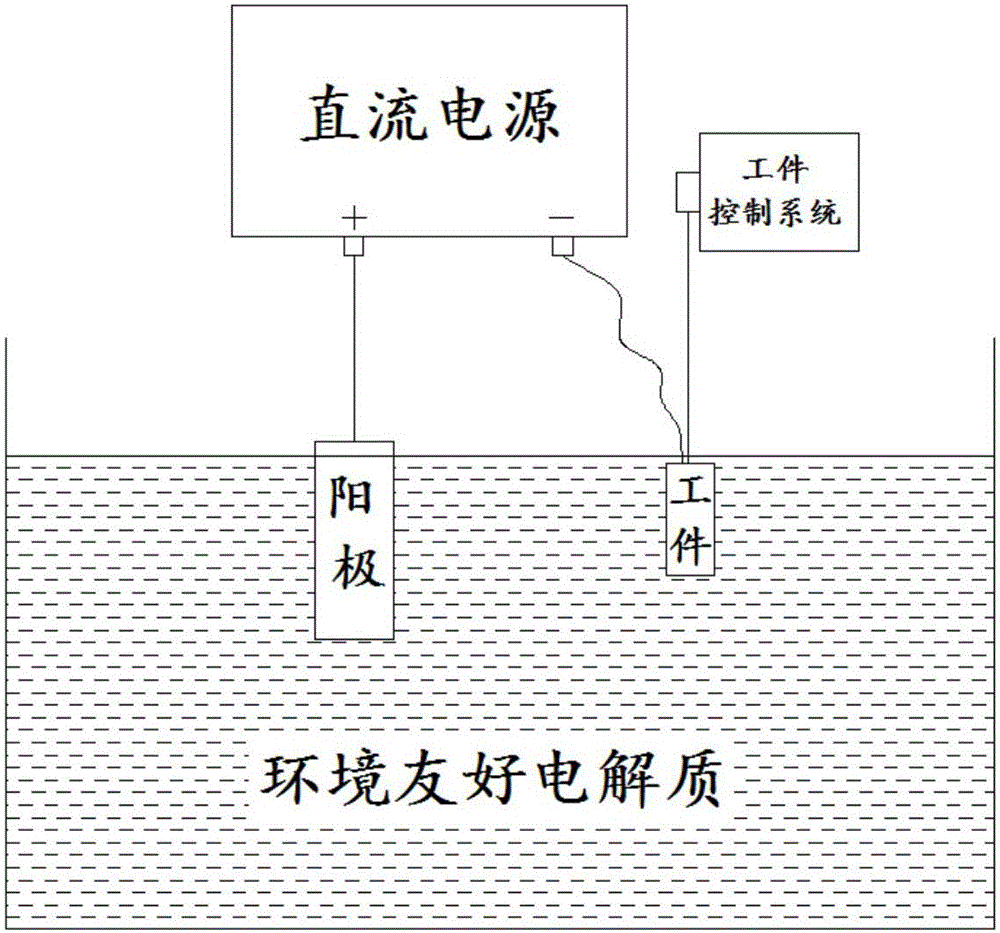

[0016] 2. Use the stainless steel plate as the anode and the steel workpiece as the cathode, and connect them to the positive and negative poles of the DC power supply (such as figure 1 shown);

[0017] 3. After immersing the anode in the cleaning solution and the cathode workpiece in the electrolyte through the workpiece control system, turn on the power and increase the voltage to 110V. After stable and continuous plasma is generated on the surface of the workpiece, keep it at this voltage for 120 seconds. Disconnect the power;

[0018] 4. Use the workpiece control system to put the workpiece into absolute ethanol for cleaning and drying....

Embodiment 2

[0020] Washing treatment in a sodium carbonate solution with a mass fraction of 10% for 300 seconds to remove the scale of the corrosion-resistant steel bars.

[0021] 1. Prepare a sodium carbonate solution with a mass fraction of 10%, pour it into the cleaning tank, and the volume of the solution exceeds two-thirds of the cleaning tank;

[0022] 2. Use the stainless steel plate as the anode and the steel workpiece as the cathode, and connect them to the positive and negative poles of the DC power supply (such as figure 1 shown);

[0023] 3. After immersing the anode in the cleaning solution and the cathode workpiece in the electrolyte through the workpiece control system, turn on the power and increase the voltage to 110V. After stable and continuous plasma is generated on the surface of the workpiece, keep it at this voltage for 300 seconds. Disconnect the power;

[0024] 4. Use the workpiece control system to put the workpiece into absolute ethanol for cleaning and drying...

Embodiment 3

[0026] Washing treatment in a sodium phosphate solution with a mass fraction of 10% for 120 seconds to remove the scale of the corrosion-resistant steel bar.

[0027] 1. Prepare a sodium phosphate solution with a mass fraction of 10%, pour it into the cleaning tank, and the volume of the solution exceeds two-thirds of the cleaning tank;

[0028] 2. Use the stainless steel plate as the anode and the steel workpiece as the cathode, and connect them to the positive and negative poles of the DC power supply (such as figure 1 shown);

[0029] 3. After immersing the anode in the cleaning solution and the cathode workpiece in the electrolyte through the workpiece control system, turn on the power and increase the voltage to 130V. After stable and continuous plasma is generated on the surface of the workpiece, keep it at this voltage for 120 seconds. Disconnect the power;

[0030] 4. Use the workpiece control system to put the workpiece into absolute ethanol for cleaning and drying....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com