Lavender absolute oil and preparation method thereof

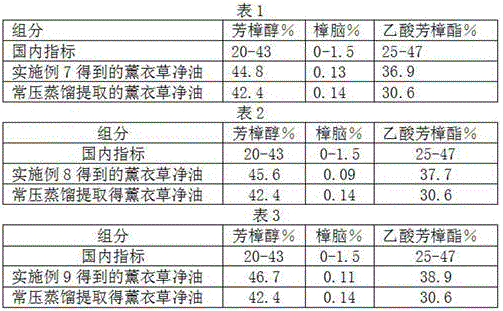

A lavender oil, lavender technology, which is applied in the direction of oil/fat refining, essential oil/spice, oil/fat production, etc., can solve the problems of high camphor content, low content of linalool and linalyl acetate, etc., To achieve the effect of long and stable aroma, lower camphor content and higher content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1, the preparation method of this lavender absolute oil is obtained according to the following steps: the first step, choose lavender extract, and the ethanol aqueous solution that the mass percentage content is 93% to 98% by lavender extract and mass percentage is 0.9 : 1.8 to 1.1: 2.2 After shaking and mixing, the mixed solution is obtained; in the second step, the frozen mixed solution is obtained after standing at -5°C to -10°C for 2 hours to 5 hours; in the third step, the frozen mixed solution is After 300 order to 400 order filter cloth filter, obtain filtrate after carrying out suction filtration with Buchner funnel again; The 4th step, filtrate obtains lavender absolute oil of the present invention after reclaiming ethanol aqueous solution.

Embodiment 2

[0020] Embodiment 2, the preparation method of this lavender absolute oil is obtained according to the following steps: the first step, choose lavender extract, and the ethanol aqueous solution that the mass percentage content is 93% to 98% by lavender extract and mass percentage is 0.9 : 1.8 to 1.1: 2.2 After shaking and mixing, the mixed solution is obtained; the second step is to stand the mixed solution at -5°C or -10°C for 2 hours or 5 hours to obtain the frozen mixed solution; the third step is to freeze the mixed solution through After 300 order or 400 order filter cloths filter, obtain filtrate after carrying out suction filtration with Buchner funnel again; The 4th step, filtrate obtains lavender absolute oil of the present invention after reclaiming ethanol aqueous solution.

Embodiment 3

[0021] Embodiment 3, as above-mentioned embodiment optimization, this lavender extract is obtained by the following method: the first step, selects lavender fresh flowers; Second step, puts lavender fresh flowers into subcritical extraction kettle, is 2Mpa to 4Mpa at extraction pressure , under the conditions of extraction temperature 30°C to 40°C, the extraction agent R134a is introduced into the subcritical extraction kettle through a booster pump with a flow rate of 8 g / min to 12 g / min for continuous extraction for 1 hour to 2 hours to obtain lavender fluid; the third The first step is to flow the lavender fluid from the subcritical extraction kettle into the subcritical separation kettle and lower it to normal temperature for separation to obtain lavender extract.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com