A kind of plastic sheet for electronic label and preparation method thereof

A technology of electronic tags and plastic sheets, which is applied in metal processing equipment, transportation and packaging, etc., can solve the problems of expensive sintered ferrite sheets and limit the wide application of electronic tags, and achieve improved reading sensitivity and good flexibility , High production efficiency and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

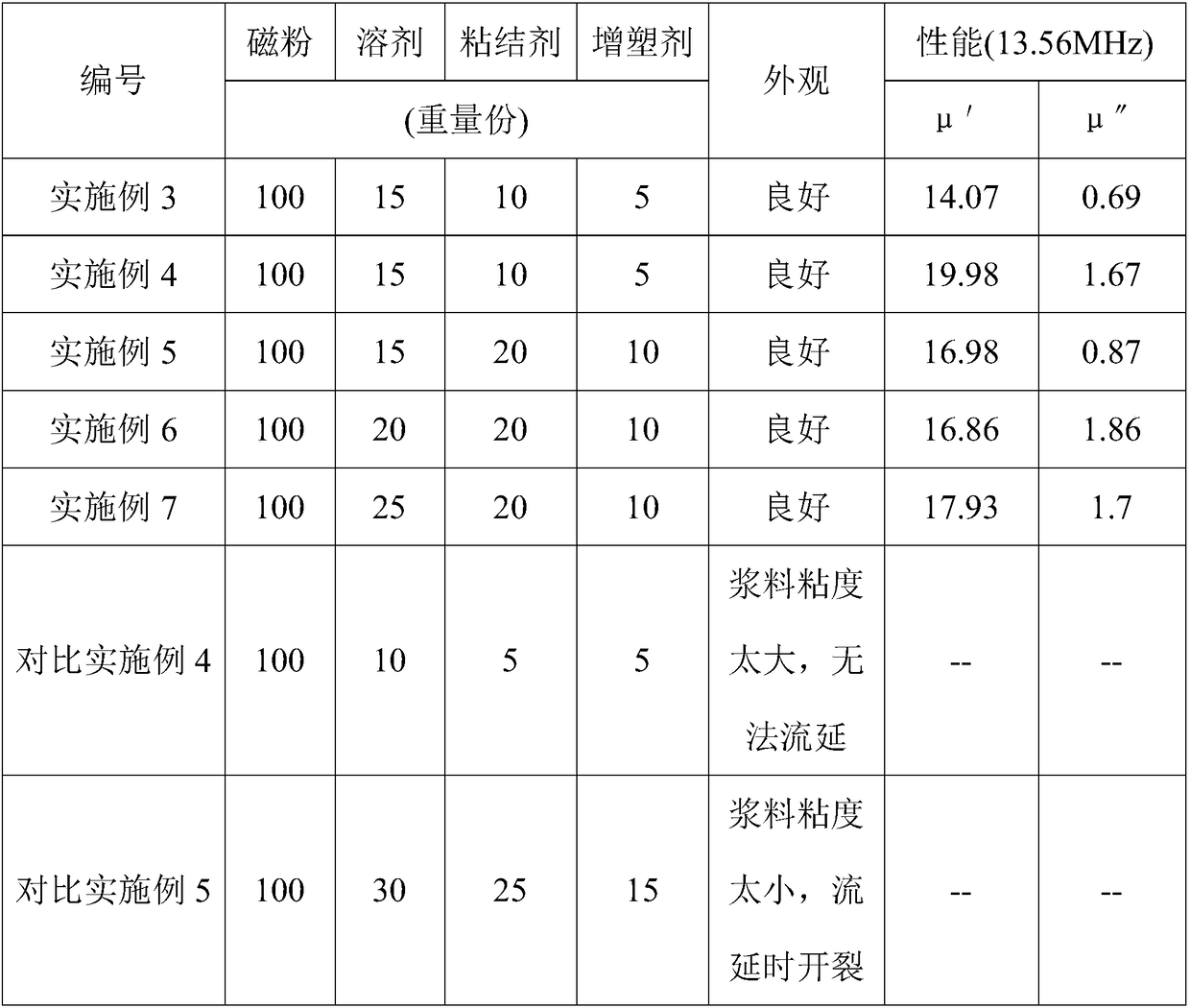

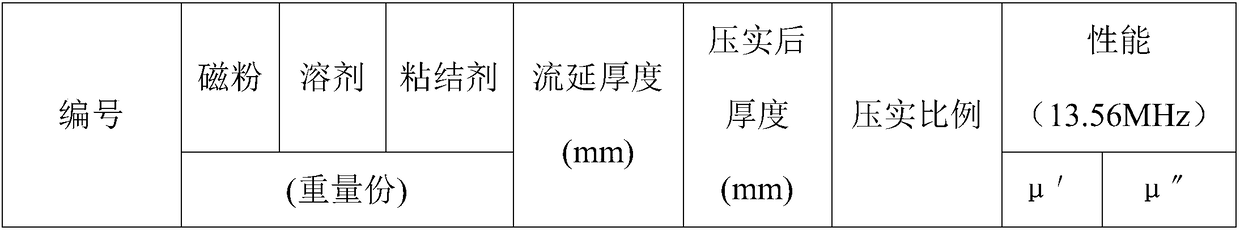

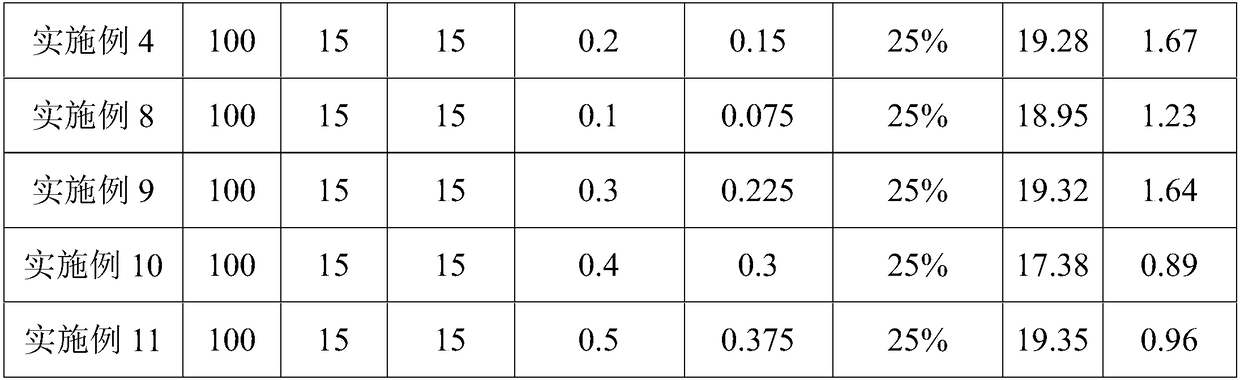

Examples

Embodiment 1

[0027] A plastic sheet for an electronic label, comprising 100 parts by weight of NiCuZn ferrite powder: 10 parts of solvent; 5 parts of binder; 3 parts of plasticizer; wherein, the NiCuZn ferrite powder is sintered into a magnetic The final nickel-zinc ferrite magnetic powder is used as raw material, and the nickel-zinc ferrite material is pressed into a magnetic ring with an outer diameter of 20mm and an inner diameter of 10mm. When testing, the performance requirements are: the frequency is 13.56MHz, and the magnetic permeability of the magnetic ring: 150-500 , The loss is 10-50.

[0028] The solvent in this embodiment is acetone; the binder is polyvinyl butyral; the plasticizer is dibutyl phthalate.

[0029] The preparation method of the plastic sheet for the above-mentioned electronic label comprises the following steps:

[0030] 1) Preparation of NiCuZn ferrite powder: use sintered nickel-zinc ferrite powder as the raw material, and press the nickel-zinc ferrite materia...

Embodiment 2

[0036] A plastic sheet for an electronic label, comprising 100 parts by weight of NiCuZn ferrite powder: 30 parts of solvent; 25 parts of binder; 15 parts of plasticizer; wherein, the NiCuZn ferrite powder is sintered into a magnetic The final nickel-zinc ferrite magnetic powder is used as raw material, and the nickel-zinc ferrite material is pressed into a magnetic ring with an outer diameter of 20mm and an inner diameter of 10mm. When testing, the performance requirements are: the frequency is 13.56MHz, and the magnetic permeability of the magnetic ring: 150-500 , The loss is 10-50.

[0037] In this embodiment, the binder is polyurethane; the plasticizer is trioctyl trimellitate; the solvent is a mixture of ethanol and toluene, forming a binary azeotropic solvent.

[0038] The preparation method of the plastic sheet for the above-mentioned electronic label comprises the following steps:

[0039] 1) Preparation of NiCuZn ferrite powder: use sintered nickel-zinc ferrite magne...

Embodiment 3

[0045] First, the high-performance NiCuZn magnetic powder after burning into magnets is passed through a 100-mesh sieve, and 100 parts by weight of the magnetic powder is taken, mixed with 15 parts by weight of a solvent (ethanol and toluene or ethanol and xylene binary mixture), and 10 parts by weight of water-soluble Polyurethane and 5 parts by weight of DBP are uniformly dispersed and poured into the ball mill tank, and the slurry obtained after ball milling and mixing for 6 hours according to the above ratio is set to a casting thickness of 0.2mm, and the slurry is dried at 40°C after tape casting. A ferrite green sheet with a thickness of 0.2mm was prepared, and the ferrite plastic sheet was cut into small pieces of 100x100mm, and rolled by a round roller press. After rolling, the thickness was 0.15mm, and the compression amount was 25%. The complex magnetic permeability of the final magnetic isolation material is tested by an Agilent 4991A impedance meter. When the freque...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com