A fast response/recovery graphene‑cotio 3 Preparation method of composite sensitive material

A fast-response, compound-sensitive technology, applied in the analysis of materials, material resistance, chemical instruments and methods, etc., can solve the problems of high minimum gas concentration, slow response speed, high working temperature, etc., and achieve fast carrier mobility, good Effects of thermal conductivity and high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

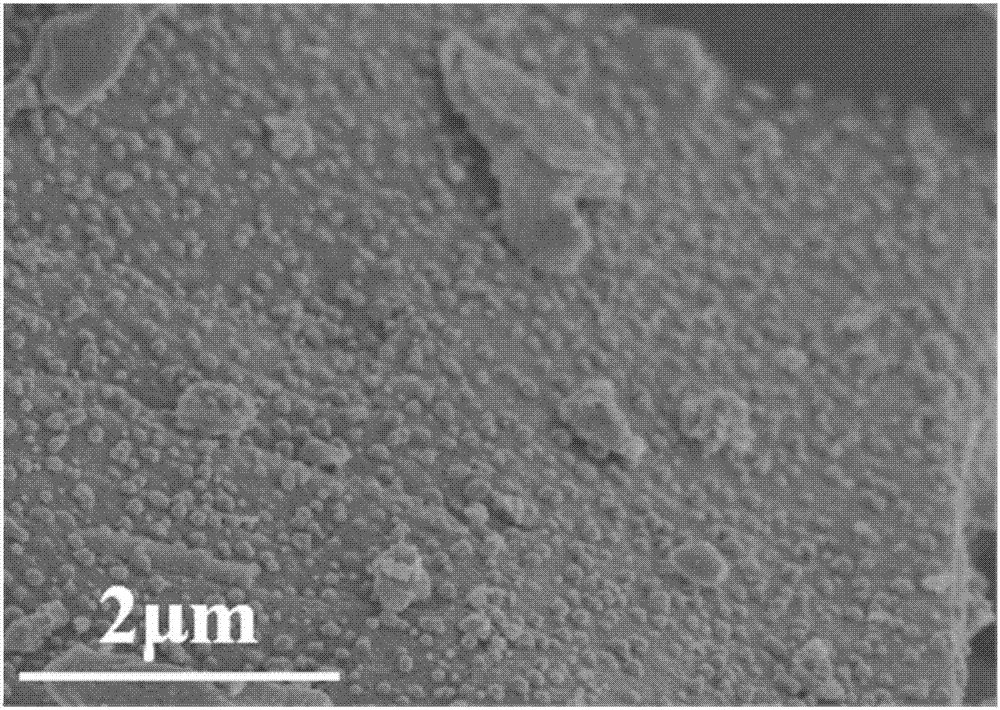

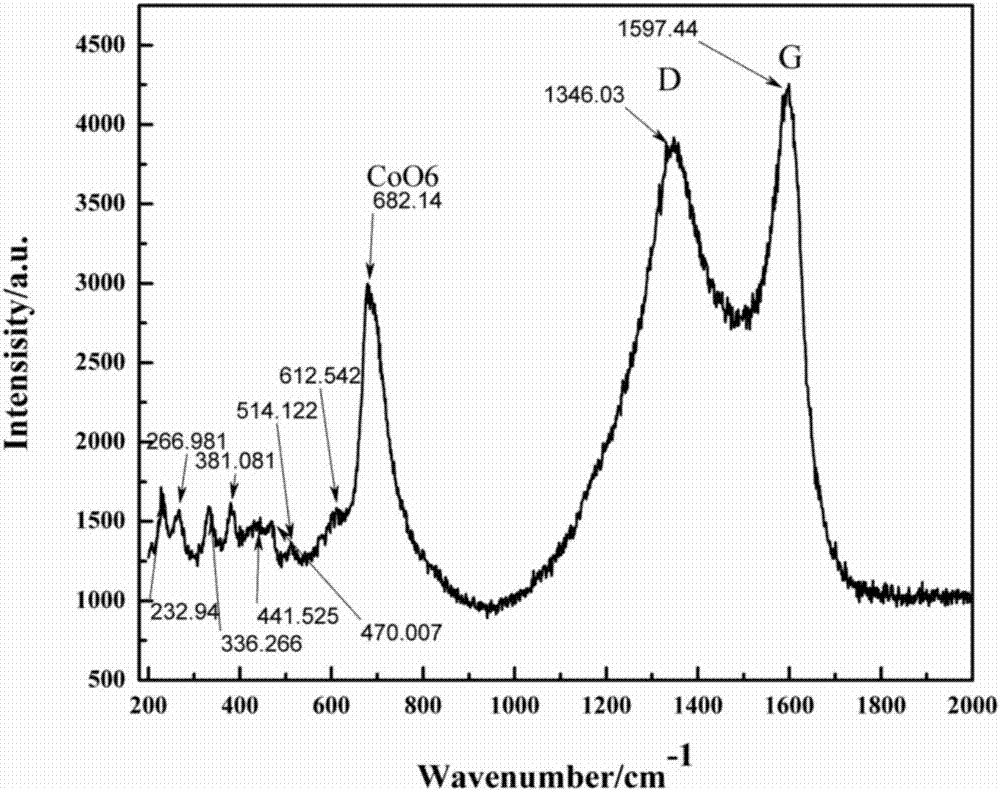

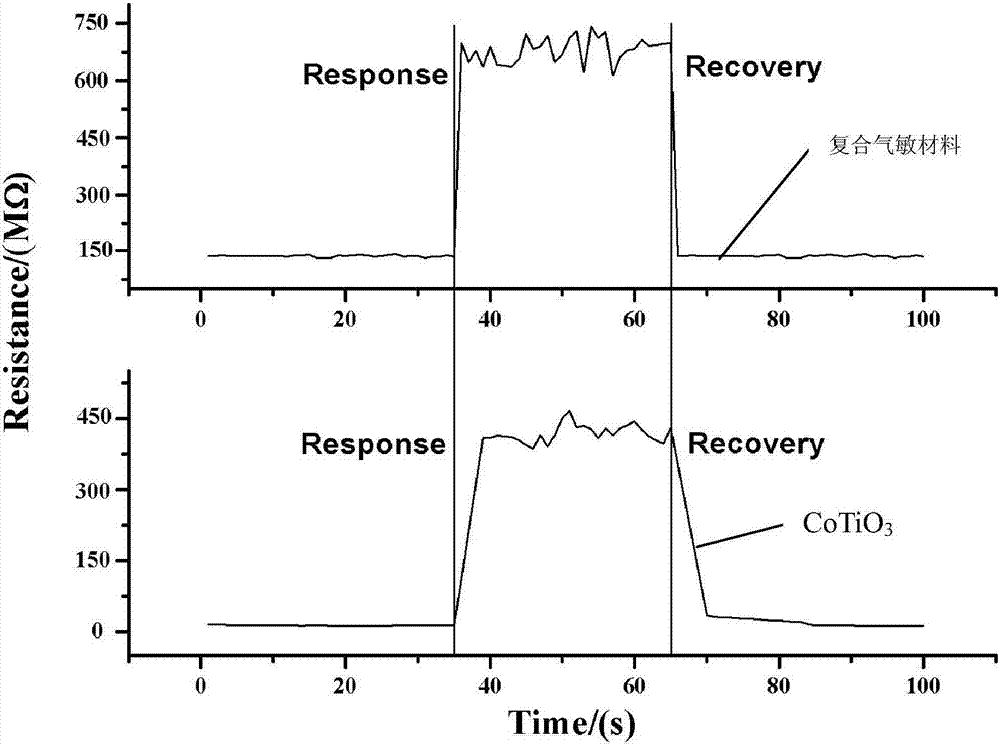

Image

Examples

Embodiment 1

[0023] 1) Add 3.125mg of graphene oxide to 3.125mL of ethanol, the concentration of graphene oxide in ethanol is 1mg / mL, ultrasonic 1.5h, ultrasonic power is 60Hz, graphene oxide is uniformly dispersed in ethanol to obtain Graphene oxide ethanol solution.

[0024] 2) Add 0.005molCo(NO 3 ) 2 ·6H 2 O was completely dissolved in 15mL C 2 h 5 OH, stirred at room temperature to obtain a uniform red transparent solution, denoted as A, at this time Co 2+ The concentration is 0.00033 mol / mL.

[0025] 3) Add 1 drop of analytically pure glacial acetic acid to A, adjust the pH value of the solution to 2.0, and obtain a reddish-brown solution, denoted as B.

[0026] 4) Slowly pour B into 0.005mol analytically pure Ti(OC 4 h 9 ) 4 In, and constantly stirring, a red transparent sol was obtained, which was recorded as C.

[0027] 5) Slowly add 3.125mL of graphene oxide ethanol solution into the above-mentioned red transparent sol, stir for 24h, and the stirring rate is 70r / min to o...

Embodiment 2

[0030] 1) Add 12.5 mg of graphene oxide to 12.5 mL of ethanol, the concentration of graphene oxide in ethanol is 1 m g / mL, ultrasonic 1.5h, ultrasonic power 60Hz, uniformly disperse graphene oxide in ethanol to obtain graphene oxide ethanol solution.

[0031] 2) Weigh 0.005molCo(NO 3 ) 2 ·6H 2 O was completely dissolved in 15mL C 2 h 5 OH, stirred at room temperature to obtain a uniform red transparent solution, denoted as A, at this time Co 2+ The concentration is 0.00033 mol / mL.

[0032] 3) Add 1 drop of analytically pure glacial acetic acid to A, adjust the pH value of the solution to 3.0, and obtain a reddish-brown solution, denoted as B.

[0033] 4) Slowly pour B into 0.005mol analytically pure Ti(OC 4 h 9 ) 4 In, and constantly stirring, a red transparent sol was obtained, which was recorded as C.

[0034] 5) Slowly add 12.5 mL of graphene oxide ethanol solution into the above-mentioned red transparent sol, stir for 24 hours, and the stirring rate is 70r / min to...

Embodiment 3

[0037] 1) The graphene oxide that weighs 31.25mg is added in the ethanol of 31.25mL, the graphene oxide in ethanol 浓 The concentration range is 1mg / mL, ultrasonic 1.5h, ultrasonic power is 60Hz, graphene oxide is uniformly dispersed in ethanol to obtain graphene oxide ethanol solution.

[0038] 2) Weigh 0.005molCo(NO 3 ) 2 ·6H 2 O was completely dissolved in 15mL C 2 h 5 OH, stirred at room temperature to obtain a uniform red transparent solution, denoted as A, at this time Co 2+ The concentration is 0.00033 mol / mL.

[0039] 3) Add 1 drop of analytically pure glacial acetic acid to A, adjust the pH value of the solution to 4.0, and obtain a reddish-brown solution, which is denoted as B.

[0040] 4) Slowly pour B into 0.005mol analytically pure Ti(OC 4 h 9 ) 4 In, and constantly stirring, a red transparent sol was obtained, which was recorded as C.

[0041] 5) Slowly add 31.25 mL of graphene oxide solution into the above-mentioned red transparent sol, stir for 24 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com