Method for removing sulfate solution chloride ions through electric absorption of three dimensional electrodes

A sulfuric acid system and three-dimensional electrode technology, applied in the field of water pollution treatment, can solve the problems of inability to treat high-concentration chlorine-containing wastewater, thin plates to limit industrial application, and poor electro-adsorption technology, saving implementation time and removing effects. Obvious, easy-to-buy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0019] Weigh 42g of activated carbon and fill it in the anode area, use lead plates and titanium plates for the cathode and anode respectively, and use a peristaltic pump to circulate and absorb 500ml of Cl at a speed of 40rpm - The concentration is 1000mg / L, SO 4 2- The adsorption solution is 1200mg / L. During the adsorption process, the pH of the solution is controlled to be 2, and the anode potential is controlled to be 0.7V, 1.0V, and 1.4V. After 2 hours of adsorption, the sample is measured.

[0020] The adsorbed solution was filtered with a 0.22 μm filter head, and the chlorine ion content was analyzed using 883 Metrohm ion chromatography. The results showed that with the increase of adsorption time, the electro-adsorption effect increased obviously, and after 2 hours, it basically tended to be stable, and the effluent concentrations were 491mg / L, 455mg / L, and 420mg / L, respectively.

Embodiment 4

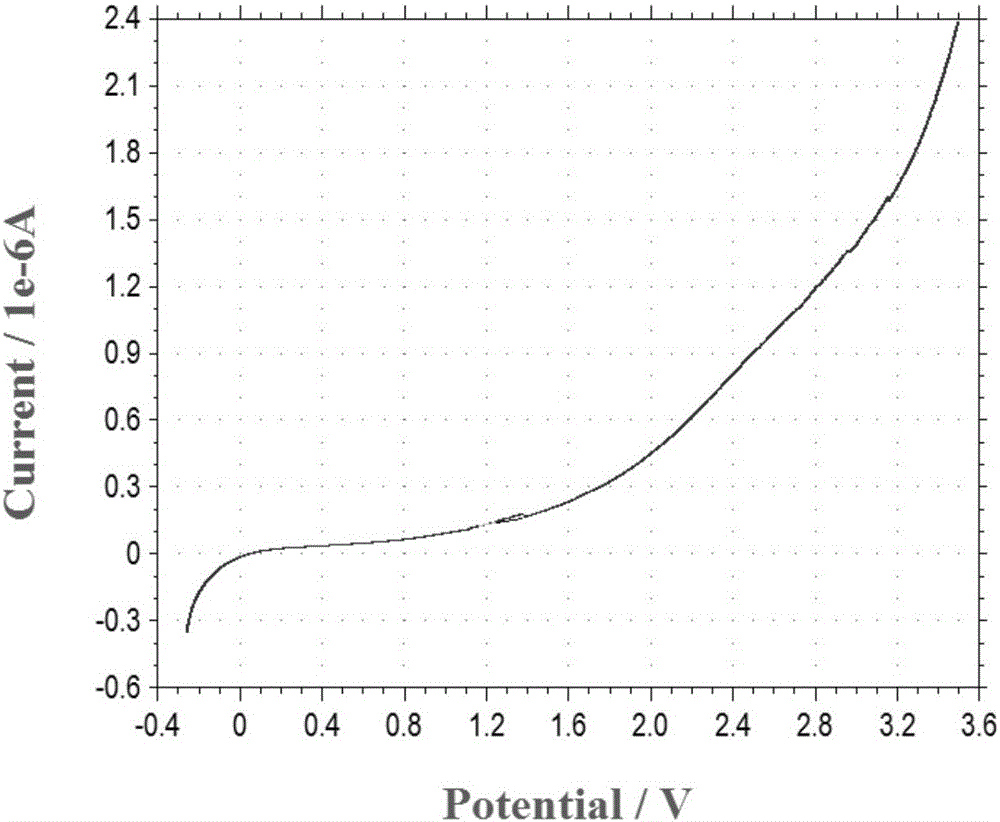

[0022] Determination of lead anodic polarization curve. The pure lead electrode is used as the working electrode, the platinum electrode is used as the counter electrode, the saturated calomel electrode is used as the reference electrode, and the concentration of Cl is 1g / L - and 2g / L of SO 4 2- As the electrolyte, the anodic polarization curve of lead was measured, from which it can be concluded that the maximum potential of anodic polarization adsorption is 1.5V.

Embodiment 5-7

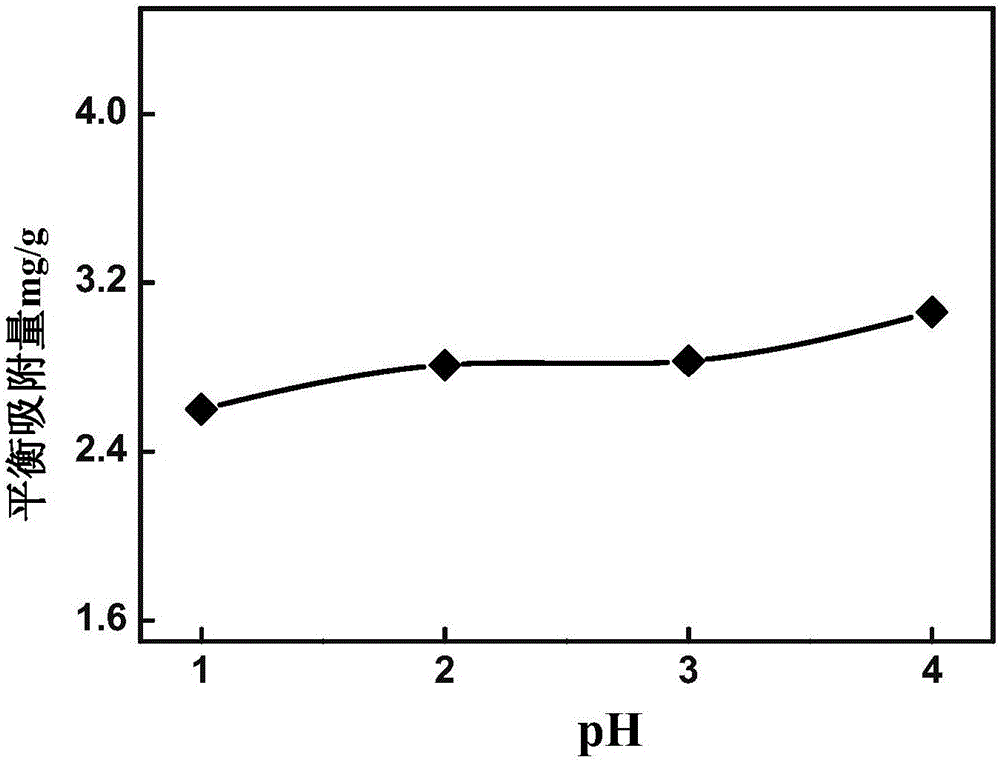

[0024] Weigh 42g of activated carbon and fill it in the anode area, use lead plates and titanium plates for the cathode and anode respectively, and use a peristaltic pump to circulate and absorb 300ml of Cl at a speed of 40rpm - The concentration is 1000mg / L, SO 4 2- The adsorption solution is 1200mg / L. During the adsorption process, the pH of the solution is controlled to be 1, 2, and 4, and the anode potential is controlled to be 1.4V. After 2 hours of adsorption, the sample is measured.

[0025] The adsorbed solution was filtered with a 0.22 μm filter head, and the chlorine ion content was analyzed using 883 Metrohm ion chromatography. The results show that under the condition of pH 1-4, the electro-adsorption effect is obvious and basically stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com