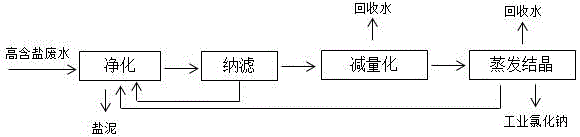

Method and system for recovering sodium chloride from high salinity wastewater

A technology with high salt content and sodium chloride, applied in chemical instruments and methods, water softening, alkali metal chlorides, etc., can solve the problems of low recycling rate, achieve the effect of reducing operating costs and obtaining economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Based on the method of recovering sodium chloride from high-salt wastewater based on the above system, the TDS of the saline wastewater discharged by reverse osmosis in a coal chemical industry is 25,000 mg / L. After the wastewater is purified by calcium chloride + soda ash + activated carbon, the solid-liquid separation The obtained supernatant enters the nanofiltration unit to separate a monovalent ion supernatant and a dope. The TDS of the monovalent ion supernatant is 10000 mg / L and the TDS of the dope is 40000 mg / L, and the dope returns to Purification unit, the clear liquid enters the reduction DTRO unit to concentrate until the concentrated liquid with a TDS of 90,000 mg / L, and the recovered water is reused; the concentrated liquid enters the evaporation crystallization unit, crystallizes and separates chlorine that meets the GB / T 5462-2003 Class II standard Sodium chloride, the condensate is reused.

Embodiment 2

[0029] Based on the method of recovering sodium chloride from high-salt wastewater based on the above system, the TDS of the saline wastewater discharged by reverse osmosis in a certain coal chemical industry is 30,000 mg / L. After the wastewater is purified by lime + flue gas, it is obtained by solid-liquid separation The clear liquid enters the nanofiltration unit to separate a monovalent ion clear liquid and a concentrated liquid. The TDS of the monovalent ion clear liquid is 15000 mg / L and the TDS of the concentrated liquid is 50000 mg / L, and the concentrated liquid is returned to the purification unit , the clear liquid enters the reduction DTRO unit to concentrate to a concentrated liquid with a TDS of 120,000 mg / L, and the recovered water is reused; the concentrated liquid enters the evaporation crystallization unit, and crystallizes to separate sodium chloride that meets the GB / T 5462-2003 Grade II standard , the condensate is reused.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com