Method for preparing 5-hydroxymethyl furfural from sugar

A technology of hydroxymethylfurfural and sugars, applied in the field of chemical preparation, can solve the problems of low yield of 5-hydroxymethylfurfural, difficulty in product separation, difficulty in preparation, etc., and achieve convenient product separation, high application value, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

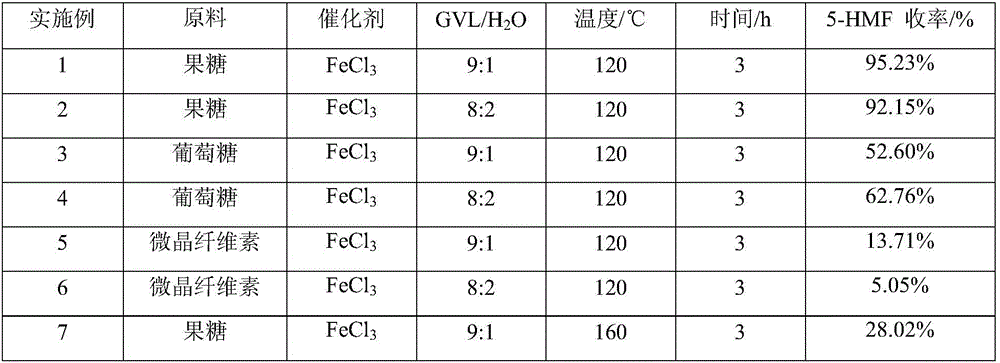

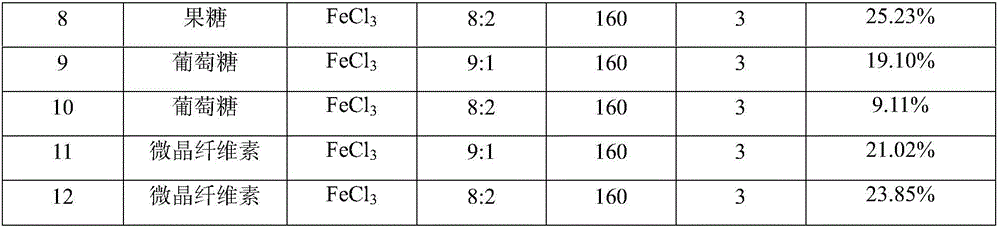

Examples

Embodiment 1

[0016] Add 0.1g fructose and 0.1g FeCl to a 15mL pressure-resistant tube 3 Catalyst, 0.5mL of water and 4.5mL of γ-valerolactone (GVL), heated to 120°C under magnetic stirring at a stirring rate of 800r / min, and continued to react with constant temperature stirring for 3h.

[0017] After the reaction is completed, cool to room temperature, sample and dilute, and measure the content of 5-hydroxymethylfurfural (5-HMF) by high-performance liquid chromatography (HPLC).

[0018] High performance liquid chromatography detection conditions: Hitachi L2000HPLC System, Alltech C18column, mobile phase CH 3 OH:H 2 O=20:80, flow rate: 1.0 mL / min, column temperature: 30° C., detector: DAD, detection wavelength: 284 nm.

[0019] It was determined by HPLC that the product of this example was 5-hydroxymethylfurfural (5-HMF), and the yield of 5-hydroxymethylfurfural (5-HMF) was 95.23%.

Embodiment 2

[0021] In this example, 5-hydroxymethylfurfural was prepared in the same manner as in Example 1, except that the amount of water was changed to 1 mL, and the amount of γ-valerolactone (GVL) was changed to 4 mL. After detection, the obtained product was 5-hydroxymethylfurfural (5-HMF), and the yield was 92.15%.

Embodiment 3

[0023] In this example, 5-hydroxymethylfurfural was prepared in the same manner as in Example 1, except that fructose was changed to glucose. After detection, the obtained product was 5-hydroxymethylfurfural (5-HMF), and the yield was 52.60%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com