Oxidation pretreatment method for strengthening arsenic containing gold concentrates through cooperation of oxidizing agent and catalyst

A gold concentrate and oxidant technology, applied in the direction of improving process efficiency, etc., can solve the problems of reduced biological oxidation rate, toxic arsenic ions, etc., achieve the effects of reducing inhibition, fast reaction rate, and improving oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

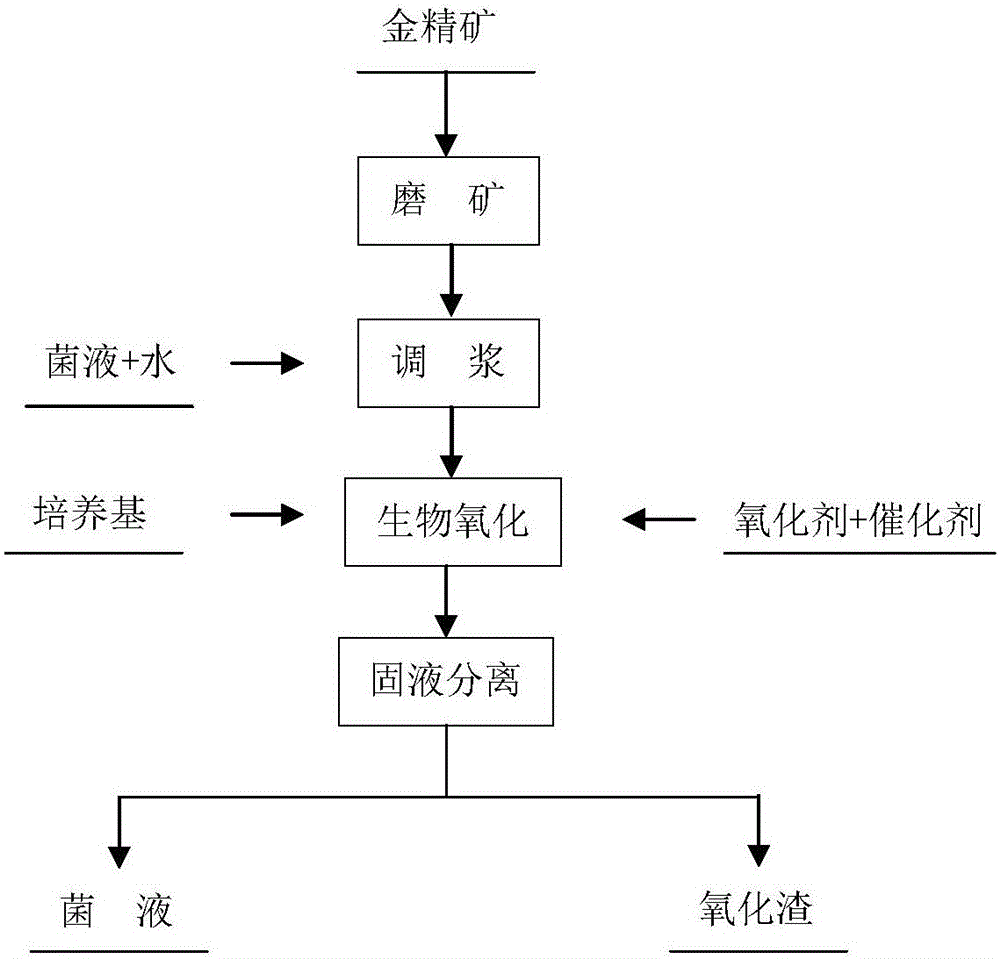

Method used

Image

Examples

Embodiment 1

[0027] (1) Grinding and grading operations

[0028] The gold concentrate with arsenic content of 13.52% and gold grade of 80g / t is ground and graded so that the ore particle size is less than 320 mesh and 90%. The gold concentrate after grinding and grading is washed twice with water and adjusted slurry, so that the gold concentrate slurry concentration is 45%;

[0029] (2) Biological oxidation operation:

[0030] Add culture medium to the ore slurry containing 1kg gold concentrate that step (1) makes, the medium consumption is to add 3kg for every ton of gold concentrate, and add water to adjust the slurry concentration to 16%; be 98% concentrated sulfuric acid adjustment with concentration When the pH value of the gold concentrate reaches 2.0, feed it into the biological oxidation system for biological oxidation, stir and oxidize for 6 days, keep the dissolved oxygen in the solution at 4mg / l, and control the reaction temperature at 40°C. Add Oxidant hydrogen peroxide 8g, c...

Embodiment 2

[0035] (1) Grinding and grading operations

[0036]The high-arsenic gold concentrate with arsenic content of 17.34% and gold grade of 93g / t is ground and graded so that the ore particle size is less than 320 mesh and 85%. The gold concentrate after grinding and grading is washed twice with water Slurry adjustment is carried out so that the concentration of the gold concentrate slurry is 35%.

[0037] (2) Biological oxidation operation:

[0038] Add culture medium to the slurry containing 1kg of gold concentrate prepared in step (1), the amount of medium is to add 5kg per ton of gold concentrate, and add water to adjust the concentration of the slurry to 12%; it is 98% concentrated sulfuric acid to adjust The pH value of the gold concentrate reaches 1.8, and it is fed into the biological oxidation system for biological oxidation. It is stirred and oxidized under air-filled conditions for 4 days. The dissolved oxygen in the solution is kept at 4.8mg / l, and the reaction temperat...

Embodiment 3

[0043] (1) Grinding and grading operations

[0044] The high-arsenic gold concentrate with arsenic content of 8.11% and gold grade of 20g / t is ground and classified so that the ore particle size is less than 320 mesh and 95%. The gold concentrate after grinding and grading is washed twice with water Slurry adjustment is carried out so that the concentration of the gold concentrate slurry is 40%.

[0045] (2) Biological oxidation operation:

[0046] Add culture medium to the ore slurry containing 1kg gold concentrate that step (1) makes, the medium consumption is to add 2kg for every ton of gold concentrate, and add water to adjust the slurry concentration to 25%; be 98% concentrated sulfuric acid adjustment with concentration The pH value of the ore pulp reaches 1.2, and it is fed into the biological oxidation system for biological oxidation. It is stirred and oxidized under air-filled conditions for 8 days. The dissolved oxygen in the solution is kept at 4.5mg / l, and the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com