A kind of non-cleaning agent and the non-cleaning fabric obtained by using the non-cleaning agent

A no-cleaning agent and fabric technology, applied in fiber treatment, liquid-repellent fibers, textiles and papermaking, etc., can solve skin damage and other problems, and achieve good waterproof and excellent water-resistant effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

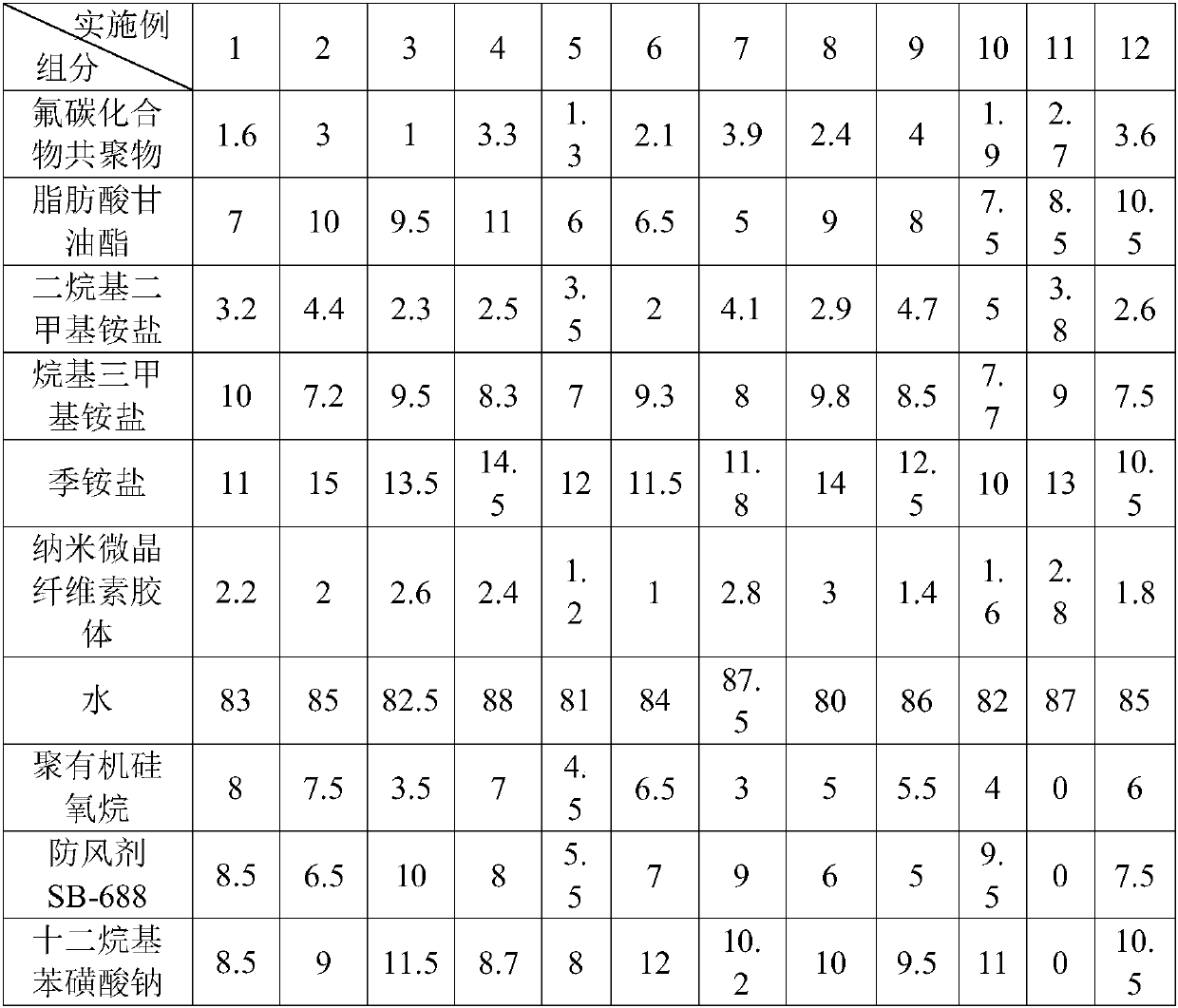

Embodiment 1-12

[0044] A kind of no-cleansing agent, it is prepared by following method:

[0045] S1. Weigh the nano-microcrystalline cellulose colloid, fluorocarbon copolymer, alkyltrimethylammonium salt and fatty acid glyceride according to the formula, put them into water, and mix thoroughly by ultrasonic;

[0046] S2. Weigh the dialkyldimethylammonium salt, polyorganosiloxane and quaternary ammonium salt according to the formula, and mix them evenly with the mixture in step S1;

[0047] S3. Weigh sodium dodecylbenzene sulfonate and windproof agent SB-688 according to the formula, and then fully mix with the remaining nano-microcrystalline cellulose colloid by ultrasonic;

[0048] S4. Ultrasonic treatment is performed on the mixture obtained in step S3 and the mixture in step S2. .

[0049] A kind of wash-free fabric, it is prepared by following steps:

[0050] S1. Add the gray cloth into the no-cleaning agent for sufficient ultrasonic impregnation;

[0051] S2, drying the fully impreg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com