Milk residue processing method and method for preparing milk products by milk residue

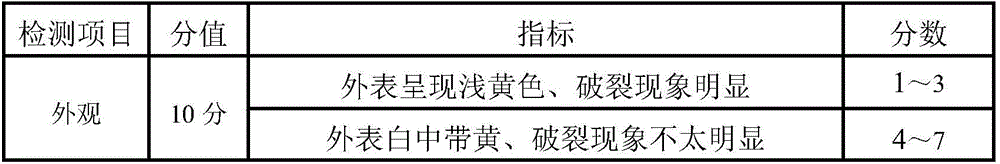

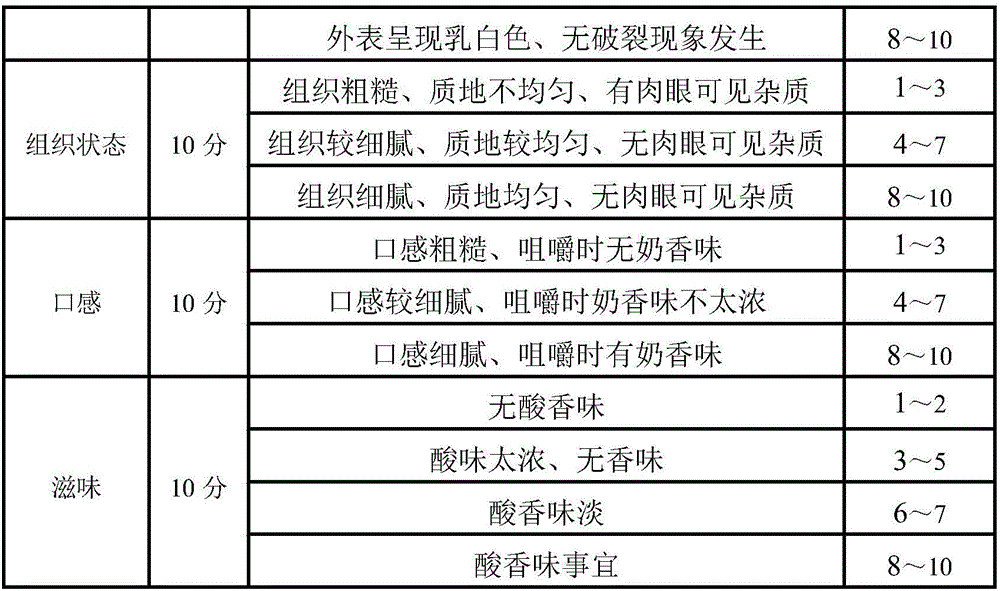

A processing method and technology for dairy products, which are applied in the directions of milk preparations, dairy products, bacteria used in food preparation, etc., can solve the problems of rough texture and taste, difficult to guarantee hygiene, uneven texture, etc., and achieve no impurities visible to the naked eye. , Appropriate sour fragrance, uniform color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment provides a milk product processing method, comprising the following steps:

[0034] (1) Take fresh milk, preheat it to 30°C, and then filter it with two layers of gauze to get raw milk after filtering out impurities;

[0035] (2) Centrifugal defatting the raw milk described in step (1) at a speed of 65 r / min to obtain skim milk with a fat content of 0.7 wt %;

[0036] (3) Sterilize the skim milk described in step (2), and the sterilization process is divided into three stages, specifically: the first stage, heat preservation at 73°C for 25min; the second stage, heat preservation at 80°C 20min; in the third stage, keep warm at 88°C for 15min;

[0037] After the sterilization treatment is completed, the temperature is rapidly lowered to 38°C to obtain unfermented milk;

[0038] (4) Add a leavening agent to the milk to be fermented in step (3), and mix well, and the starter agent accounts for 0.5% by mass of the milk to be fermented, and then ferment at 3...

Embodiment 2

[0047] This embodiment provides a milk product processing method, comprising the following steps:

[0048] (1) Take fresh milk, first preheat it to 40°C, and then filter it with 4 layers of gauze to get raw milk after filtering out impurities;

[0049] (2) centrifuging the raw milk described in step (1) at a speed of 75 r / min to obtain skim milk with a fat content of 0.6 wt %;

[0050] (3) Sterilize the skim milk described in step (2), and the sterilization process is divided into three stages, specifically: the first stage, heat preservation at 74°C for 20 minutes; the second stage, heat preservation at 86°C 15min; in the third stage, keep warm at 96°C for 5min;

[0051] After the sterilization treatment is completed, the temperature is rapidly lowered to 42°C to obtain fermented milk;

[0052](4) Add a starter to the milk to be fermented in step (3), mix well and evenly, the starter is 1% by mass of the milk to be fermented, and then ferment at 45°C for 8 hours to obtain a...

Embodiment 3

[0061] This embodiment provides a milk product processing method, comprising the following steps:

[0062] (1) Take fresh milk, preheat it to 35°C, and then filter it with 3 layers of gauze to get raw milk after filtering out impurities;

[0063] (2) Centrifugal defatting the raw milk described in step (1) at a speed of 70 r / min to obtain skim milk with a fat content of 0.5 wt %;

[0064] (3) The skim milk described in step (2) is sterilized, and the sterilizing treatment is divided into three stages, specifically: the first stage, heat preservation at 73.5°C for 22min; the second stage, heat preservation at 82°C 18min; in the third stage, keep warm at 92°C for 10min;

[0065] After the sterilization treatment is completed, the temperature is rapidly lowered to 40°C to obtain fermented milk;

[0066] (4) Add a leavening agent to the milk to be fermented in step (3), and mix well, the mass percentage of the leavening agent in the milk to be fermented is 0.8%, and then ferment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com