Porous styptic powder and preparation method thereof

A technology of hemostatic powder and radiation irradiation, which is applied in the field of preparation of porous cross-linked hemostatic powder, can solve the problems of low specific surface area, limit the application development of high-adsorption materials, and large pore size of porous cross-linked gelatin sponge, and achieve large specific surface area, Small pore size and strong adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Dissolve 15 grams of gelatin in 85 grams of water and stir well to obtain a 15% gelatin solution. Pour the gelatin solution into the mold, quickly put it into a refrigerator preset at -20°C, and quickly cool it down from room temperature to -20°C, store it for 24 hours, and quickly transfer it to a portable refrigerator with a measured temperature of 0°C ( containing ice-water mixture), cobalt-60 gamma ray irradiation dose is 30kGy to obtain hydrogel. Transfer the hydrogel to a freeze dryer for pre-freezing, the pre-freezing temperature is -80°C, and then dry to obtain a porous material. The obtained porous material is pulverized and sieved with a 100-mesh sieve to obtain a porous cross-linked powder. The joint degree is 48.7±2.1%, tested with ASAP 2010BET specific surface tester (Micromeritics, USA), the BET specific surface area is 103.71m 2 / g, 24h water absorption rate is 2216.0±7.5%.

Embodiment 2

[0027] Dissolve 1 gram of collagen in 99 grams of water and stir well to obtain a 1% collagen solution. Pour the collagen solution into the mold, quickly put it into an ultra-low temperature refrigerator set at -70°C, and quickly cool it down from room temperature to -70°C, then store it for 24 hours, and quickly transfer it to a portable refrigerator with a temperature of -10°C Inside, the collagen hydrogel was obtained by irradiating 1 kGy with electron beam radiation. Transfer to a freeze dryer for pre-freezing. The pre-freezing temperature is -20°C. After freeze-drying, the obtained porous collagen cross-linked sponge has a water absorption rate of 1634.0 ± 279.0% in 24 hours.

Embodiment 3

[0029] Dissolve 15 grams of carboxymethyl chitosan in 85 grams of water and stir evenly to obtain a 15% carboxymethyl chitosan solution. Pour the solution into a mold, and quickly put it into liquid nitrogen at a temperature of -196°C for rapid cooling, so that the temperature is rapidly dropped from room temperature to -196°C. Then store for 24 hours, quickly transfer to a portable refrigerator with a preset temperature of -20°C, irradiate with cobalt-60γ-rays at a dose of 30kGy, transfer to a freeze dryer for pre-freezing, and the pre-freezing temperature is -70°C. Carry out drying, the obtained porous material is pulverized, sieved with 100 mesh sieves, is tested with ASAP 2010BET specific surface tester (Micromeritics, USA), obtains that BET specific surface area is 52.17m 2 / g, the degree of crosslinking is 24.6±3.3%, and the 24h water absorption rate is 1800.7±10.6%.

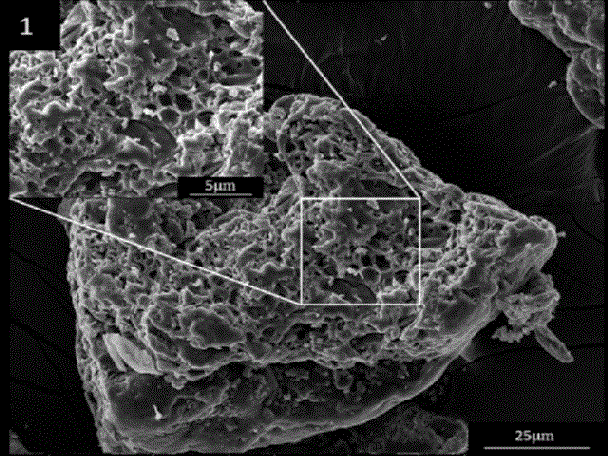

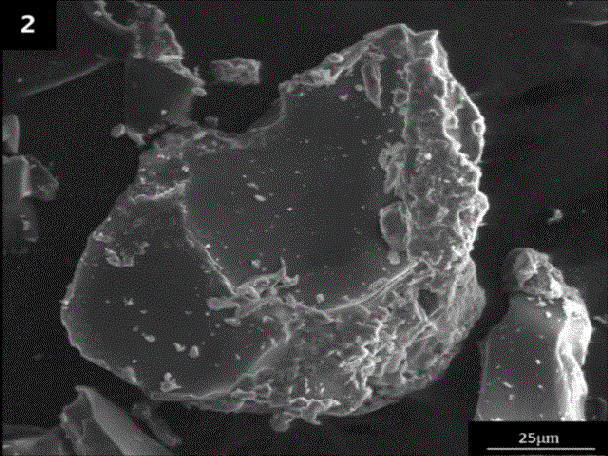

[0030] figure 1 The microstructure of the porous powder prepared according to the method of Example ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com