Preparation method of complex phase porous scaffold structure based on temperature regulation and control of complex phase apatite ingredients

A complex phase apatite and porous scaffold technology, applied in the field of biomedical materials, can solve problems such as complex process, and achieve the effect of simple process flow and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment includes the following steps:

[0032] Step 1, weighing apatite, PMMA, SDS and ammonium bicarbonate according to the ratio of 8:6:11:3 parts by weight;

[0033] Step 2, putting hydroxyapatite, PMMA and SDS into a glass container, stirring evenly with a machine;

[0034] Step 3, dissolving ammonium bicarbonate in ultrapure water at a ratio of 1:1;

[0035] Step 4, drop the ammonium bicarbonate solution into the mixed powder, and stir evenly;

[0036] Step 6, put in an oven, dry at 70°C, take out the block after drying, and put it in a crucible;

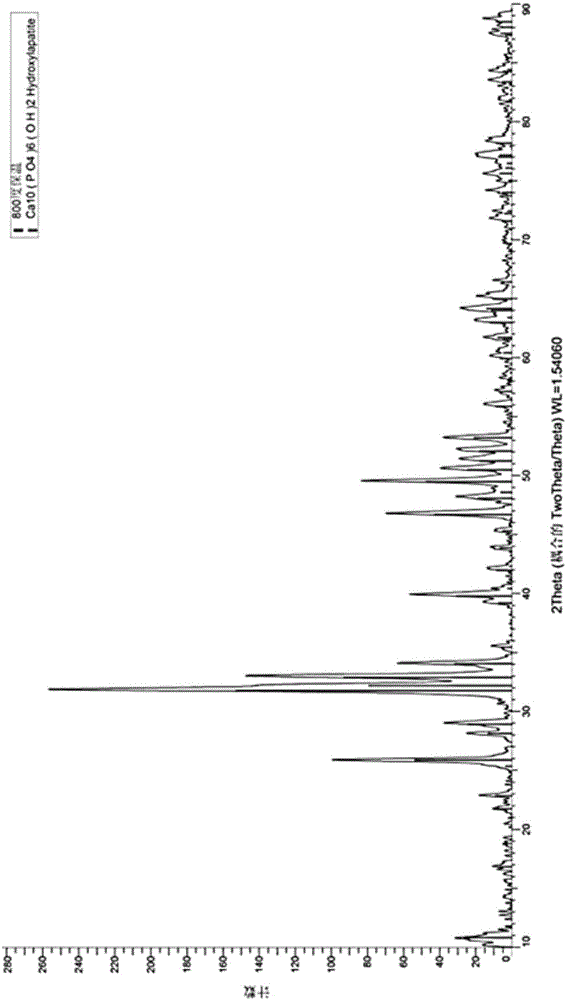

[0037] Step 7, put the crucible into a high-temperature heating furnace, and raise the temperature to 600°C at 4°C / min for 0.5 hours;

[0038] Step 8, continue to heat up at 2°C / min to 800°C for 3 hours;

[0039] In step 9, the crucible is taken out after cooling with the furnace to obtain a porous scaffold composed of hydroxyapatite and α‐TCP (<5wt%) multiphase components.

[0040] This embodiment relates t...

Embodiment 2

[0043] This embodiment includes the following steps:

[0044] Step 1, weighing hydroxyapatite, PMMA, SDS and ammonium bicarbonate according to the ratio of 8:6:11:3 parts by weight;

[0045] Step 2, putting hydroxyapatite, PMMA and SDS into a glass container, stirring evenly with a machine;

[0046] Step 3, dissolving ammonium bicarbonate in ultrapure water at a ratio of 1:1;

[0047] Step 4, drop the ammonium bicarbonate solution into the mixed powder, and stir evenly;

[0048] Step 6, put in an oven, dry at 70°C, take out the block after drying, and put it in a crucible;

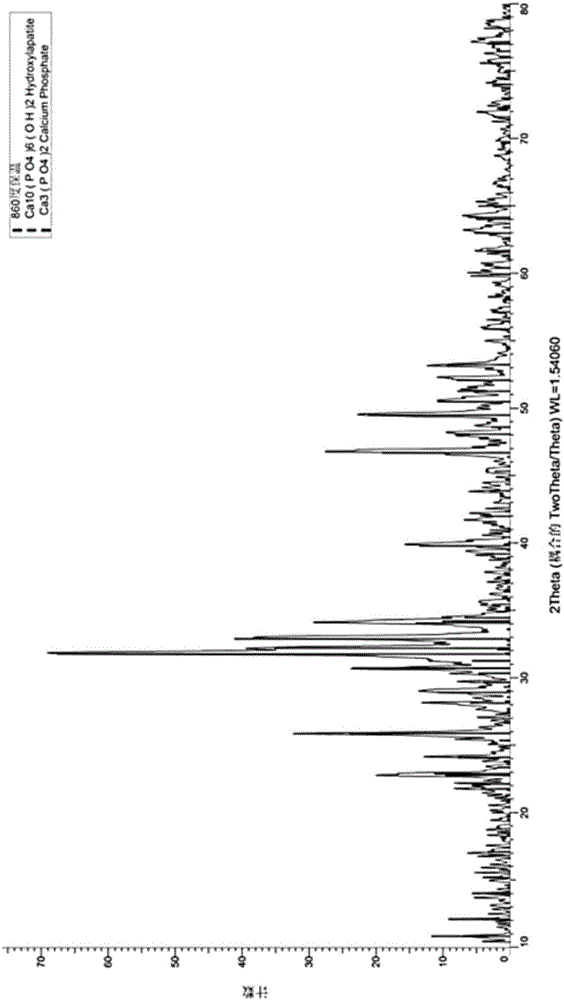

[0049] Step 7, put the crucible into a high-temperature heating furnace, and raise the temperature to 600°C at 4°C / min for 0.5 hours;

[0050] Step 8, continue to heat up at 2°C / min to 860°C for 5 hours;

[0051] Step 9, take out the crucible after cooling with the furnace, and obtain a porous scaffold of hydroxyapatite (58%) and α-TCP (42%) multiphase.

[0052] This embodiment relates to the XRD spec...

Embodiment 3

[0055] This embodiment includes the following steps:

[0056] Step 1, weighing hydroxyapatite, PMMA, SDS and ammonium bicarbonate according to the ratio of 8:6:11:3 parts by weight;

[0057] Step 2, putting hydroxyapatite, PMMA and SDS into a glass container, stirring evenly with a machine;

[0058] Step 3, dissolving ammonium bicarbonate in ultrapure water at a ratio of 1:1;

[0059] Step 4, drop the ammonium bicarbonate solution into the mixed powder, and stir evenly;

[0060] Step 6, put in an oven, dry at 70°C, take out the block after drying, and put it in a crucible;

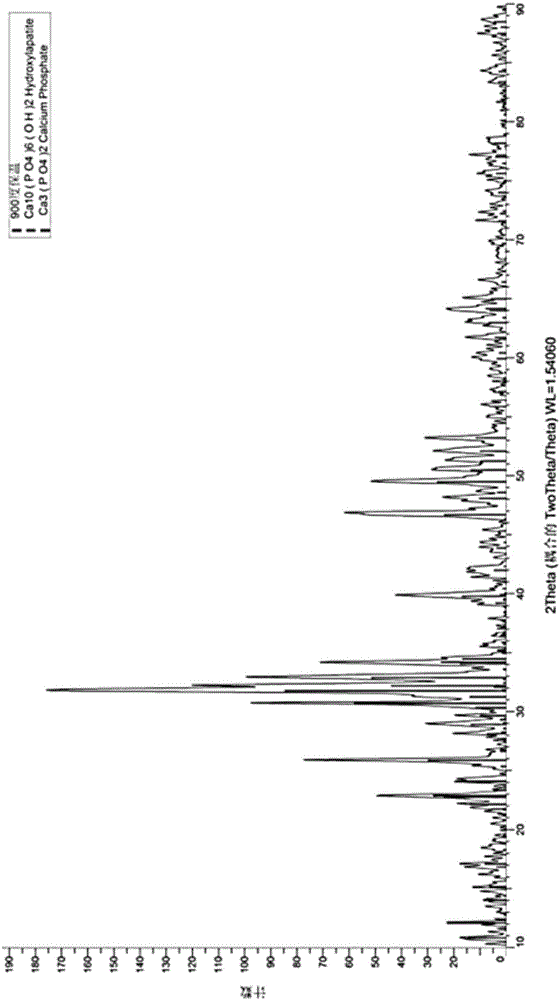

[0061] Step 7, put the crucible into a high-temperature heating furnace, and raise the temperature to 600°C at 4°C / min for 1 hour;

[0062] Step 8, continue to heat up at 2°C / min to 900°C for 4 hours;

[0063] Step 9, after cooling with the furnace, take out the crucible to obtain a multi-phase porous scaffold composed of hydroxyapatite (55%) and α‐TCP (45%).

[0064]This embodiment relates to the XRD...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com