Preparation method and application of montmorillonoid and carbon composite material

A technology of carbon composite materials and montmorillonite, which is applied in the intersecting field of environment and materials, can solve the problems of expensive adsorbent, difficulty in separation, and restricted utilization, and achieve good removal effect, simple preparation, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

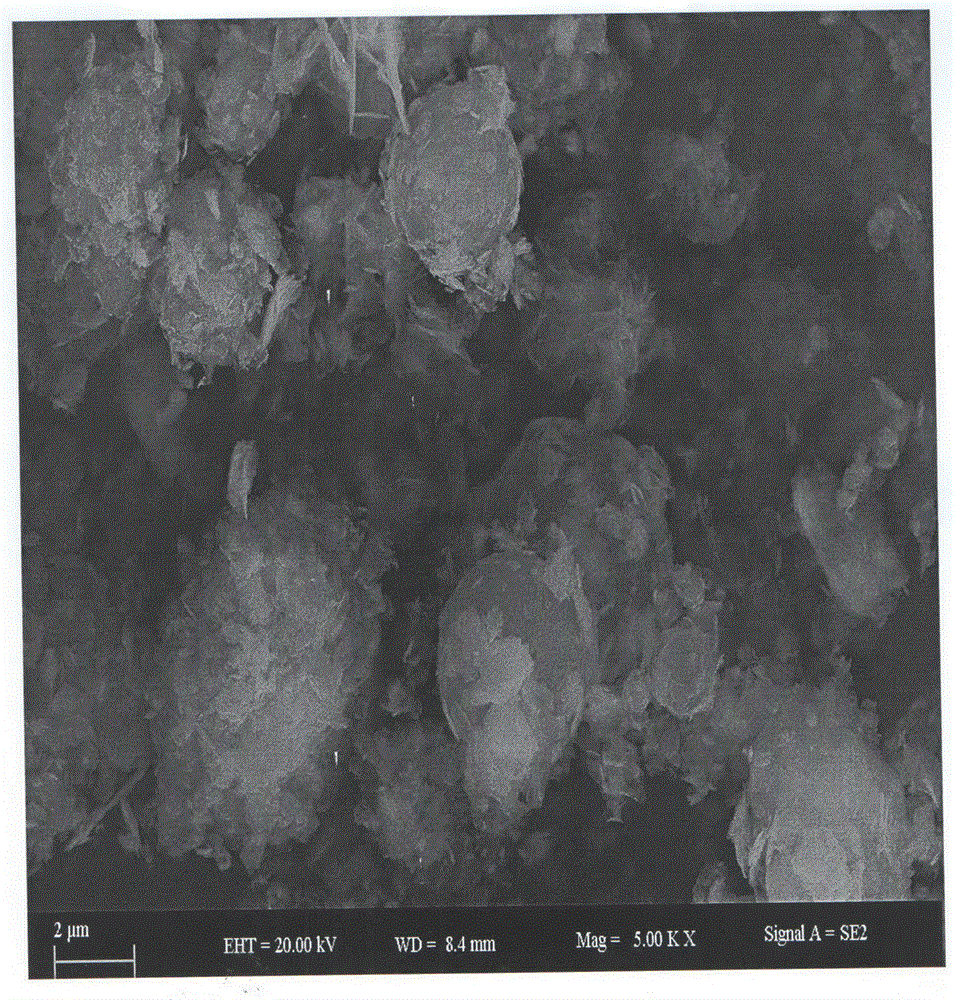

[0022] Embodiment 1 (montmorillonite and carbon composite material)

[0023] a. Purification and sodiumization of montmorillonite: Take 20g of montmorillonite and add it to 400mL of deionized water and stir evenly, then let it stand still. After layering, pour out the residue at the bottom, and continue to use the supernatant. To obtain higher-purity montmorillonite, add 100 mL of deionized water to montmorillonite and slowly stir to form a uniform mixed solution, then add 1 g of sodium chloride solid, and continue stirring to obtain a uniformly mixed slurry, then centrifuge the slurry, add deionized Ionized water, washed several times until the chloride ions are washed away, and finally dried to obtain sodium-based montmorillonite;

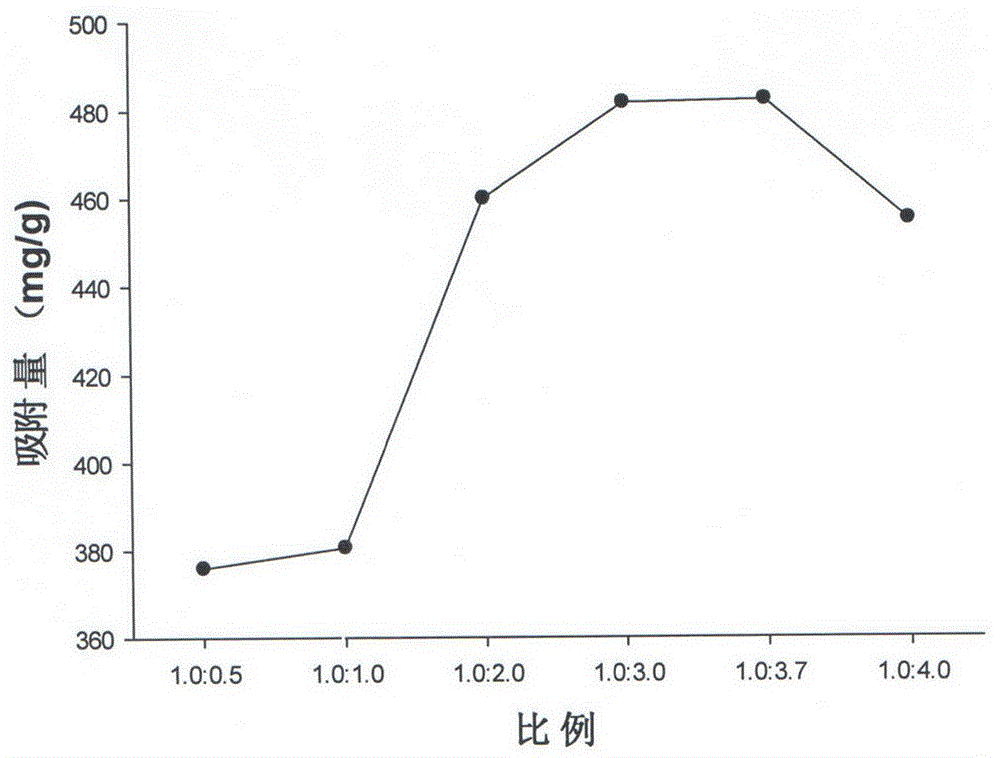

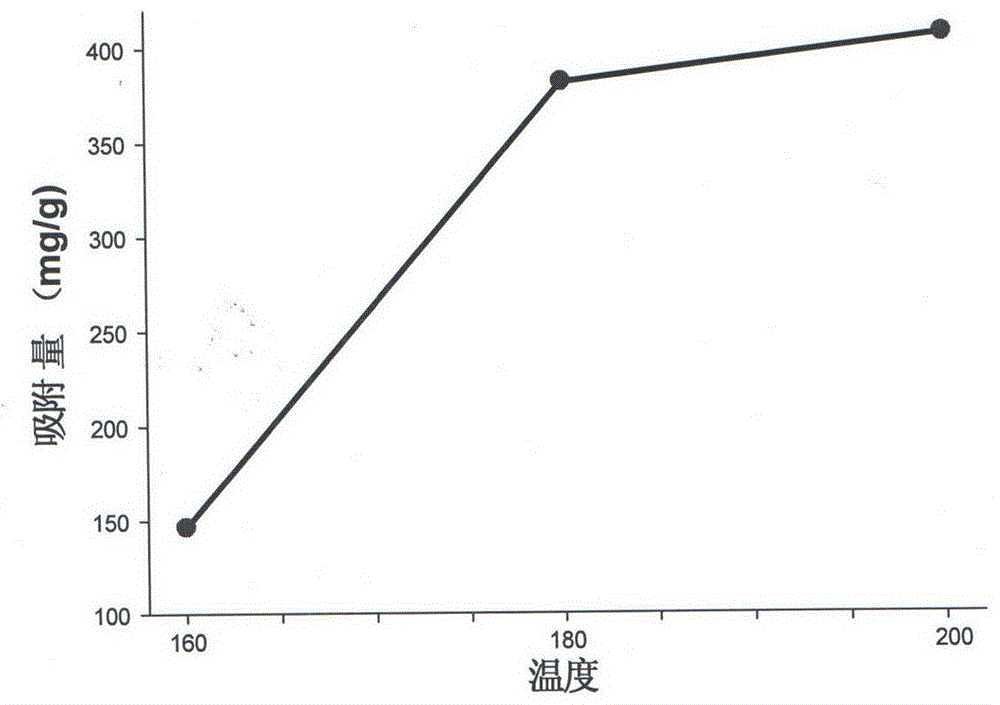

[0024] b. Preparation of montmorillonite and carbon composite materials: Weigh the sodium-based montmorillonite in step a, add deionized water, and ultrasonically treat for half an hour to form a uniform mixture, and mix in a mass ratio of 1:0.5-...

Embodiment 10

[0029] Add 0.4g / L of montmorillonite and carbon composite adsorbent prepared in Example 5 into lead-containing 300mg / L sewage, then adjust to pH=6 and temperature 303K, shake the sewage at 150rpm for 27 hours, After separation, the purpose of adsorption and removal of heavy metal lead ions can be achieved. The treated water sample was measured, and the adsorption capacity of the adsorbent was 550.00 mg / g, and the removal rate of lead ions was 73.30%.

Embodiment 11

[0030] Example 11 (Carboxylated Montmorillonite and Carbon Composite)

[0031]a. Purification and sodiumization of montmorillonite: Take 10g of montmorillonite and add it into 200mL deionized water and stir evenly, then let it stand still. , to obtain higher purity montmorillonite, add 100mL deionized water to montmorillonite and slowly stir to form a uniform mixed solution, then add 1.0g of sodium chloride solid, continue stirring to obtain a uniformly mixed slurry, then centrifuge the slurry, Add deionized water, wash repeatedly until the chloride ions are washed away, and finally dry to obtain sodium-based montmorillonite;

[0032] b. Preparation of montmorillonite and carbon composite material: Weigh 2 g of sodium-based montmorillonite in step a and add 20 mL of deionized water, ultrasonically treat for half an hour to form a uniform mixed solution, and add it to the mixed solution at a mass ratio of 1:3.7 Add glucose monohydrate and stir vigorously for 50 minutes to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com