Preparation method and application of cow dung biological carbon

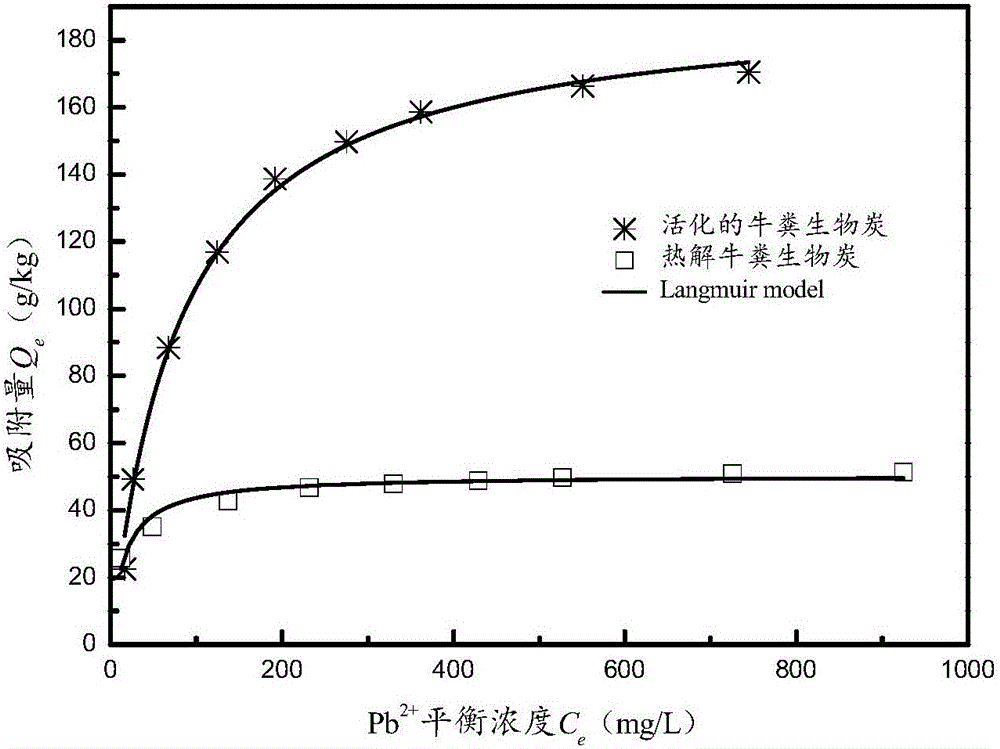

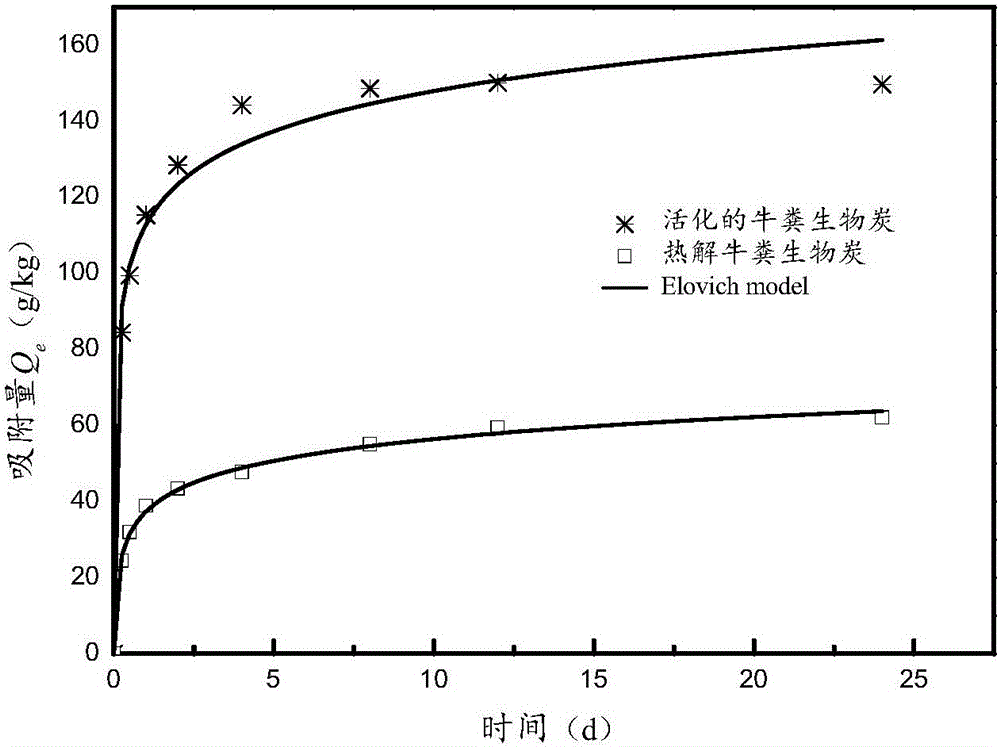

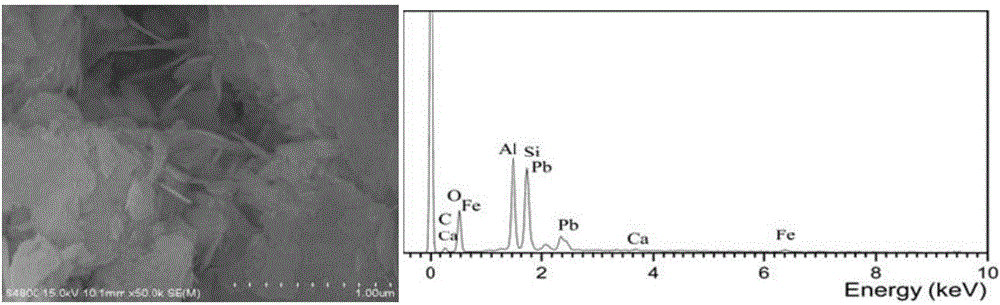

A biochar, cow dung technology, applied in chemical instruments and methods, other chemical processes, restoration of polluted soil, etc., can solve the problems of limited adsorption sites, limited adsorption performance and stability, and achieve improved adsorption performance, Profound social significance and economic value, good stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 A kind of preparation method of cow dung biochar

[0031] 1) Naturally air-dry the cow dung, crush it, and pass it through a 40-mesh sieve;

[0032] 2) Put the sieved powder in a vacuum tube furnace, seal it, and pyrolyze it under the condition of isolating the air; the specific process of pyrolysis is divided into: a heating section, a heat preservation section and a cooling section; the heating section is divided into 5~ 20°C min −1 The heating rate is raised to 200-500°C; the holding section is 2-5 hours at 200-500°C; the cooling section is natural cooling; nitrogen is used as a protective gas during the entire pyrolysis process, and the gas flow rate is 100 mL min −1 .

[0033] 3) Mix the pyrolyzed product with granular potassium hydroxide, add water, and heat at 180 rpm min −1 Stir for 180 min, filter, and take the filter residue;

[0034] Wherein, the mass ratio of pyrolyzed product to granular potassium hydroxide is 1:1.

[0035] 4) Wash the fil...

Embodiment 2

[0036] Embodiment 2 A kind of preparation method of cow dung biochar

[0037] 1) Naturally air-dry the cow dung, crush it, and pass it through a 40-mesh sieve;

[0038] 2) Put the sieved powder in a vacuum tube furnace, seal it, and pyrolyze it under the condition of isolating the air; the specific process of pyrolysis is divided into: heating section, holding section and cooling section; min −1 The heating rate was raised to 500°C; the heat preservation section was held at 500°C for 3 hours; the temperature drop section was natural cooling; nitrogen was used as a protective gas during the entire pyrolysis process, and the gas flow rate was 100 mL min −1 .

[0039] 3) Mix the pyrolyzed product with sodium hydroxide, add water, and heat at 160 rpm min −1 Stir for 6h, filter, and take the filter residue;

[0040] Wherein, the mass ratio of pyrolyzed product to sodium hydroxide is 1:0.5.

[0041] 4) Wash the filter residue with water and dry at 80°C to obtain cow dung biocha...

Embodiment 3

[0042] Embodiment 3 A kind of preparation method of cow dung biochar

[0043] 1) Naturally air-dry the cow dung, crush it, and pass it through a 40-mesh sieve;

[0044] 2) Put the sieved powder in a vacuum tube furnace, seal it, and pyrolyze it under the condition of isolating the air; the specific process of pyrolysis is divided into: heating section, holding section and cooling section; min −1 The heating rate was raised to 400°C; the heat preservation section was held at 400°C for 5 hours; the temperature drop section was natural cooling; nitrogen was used as a protective gas during the entire pyrolysis process, and the gas flow rate was 100 mL min −1 .

[0045] 3) Mix the pyrolyzed product with granular potassium hydroxide, add water, and −1 Stir for 2h, filter, and take the filter residue;

[0046] Wherein, the mass ratio of pyrolyzed product to granular potassium hydroxide is 1:0.5.

[0047] 4) Wash the filter residue with water and dry at 100°C to obtain cow dung b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com