Protective casing with oxidation corrosion resistance and thermal shock resistance and a preparation method thereof

A technology for protecting casing and impact performance, applied in the field of protective casing and its preparation, can solve the problems of rupture and damage of the protective casing, affecting the smooth operation of equipment, poor thermal shock resistance performance, etc. Avoid the damage of protective casing and increase the effect of high temperature impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

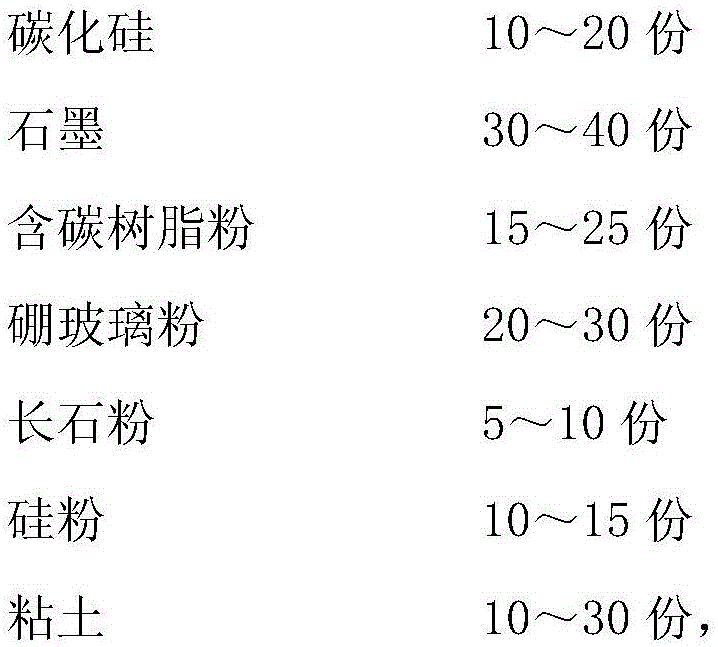

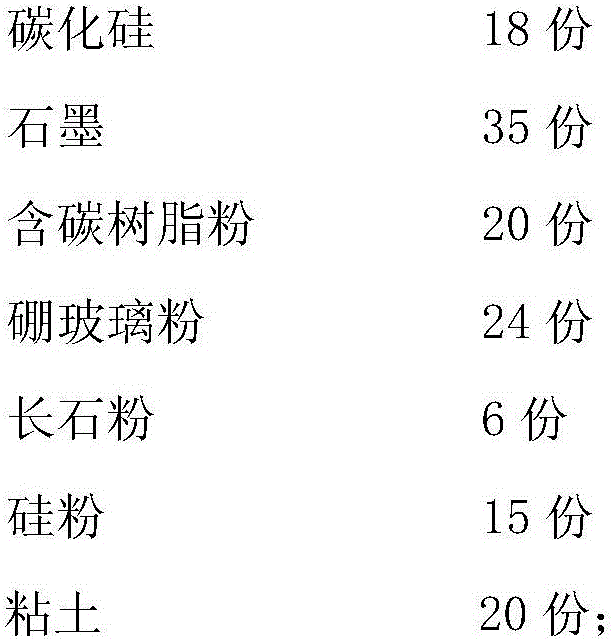

[0016] A protective casing with both oxidation resistance and thermal shock resistance, the composition of the casing includes the following components in parts by weight:

[0017]

[0018] Mix the above-mentioned components uniformly and dry at 65°C for 40 minutes, press the whole body under a pressure of 100 bar for 30 minutes to shape, then fire at 1250°C for 48 hours, and cool naturally to obtain a protective sleeve.

[0019] The bushing prepared in this example was put from room temperature into a high temperature environment of 800°C for 25 minutes, then taken out from the high temperature environment and cooled naturally at room temperature. This experiment process was repeated 1200 times, and the bushing did not break.

[0020] Submerge 2 / 3 of the casing prepared in this example in the high-temperature zinc-aluminum alloy liquid, take it out after four months and rinse the surface of the casing, and no thinning of the casing is found; while commercially available com...

Embodiment 2

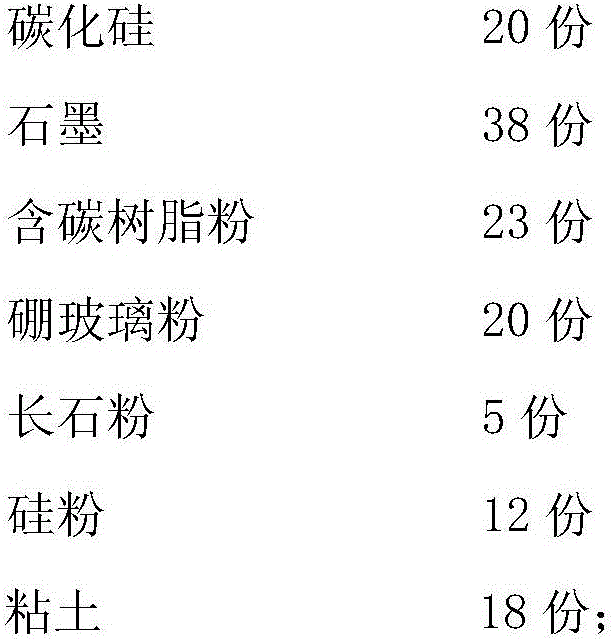

[0022] A protective casing with both oxidation resistance and thermal shock resistance, the composition of the casing includes the following components in parts by weight:

[0023]

[0024] The preparation process of the casing is as in Example 1.

[0025] The bushing prepared in this example was put from room temperature into a high temperature environment of 800°C for 25 minutes, then taken out from the high temperature environment and cooled naturally at room temperature. This experiment process was repeated 1200 times, and the bushing did not break.

[0026] Submerge 2 / 3 of the sleeve prepared in this example in the same zinc-aluminum alloy solution as in Example 1, take it out after four months and rinse the surface of the sleeve, no thinning of the sleeve was found .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com