A quenched and tempered X52 hydrogen sulfide corrosion resistant seamless line pipe and its preparation method

A seamless line pipe, anti-hydrogen sulfide technology, applied in the field of line pipe manufacturing, can solve problems such as cost increase and negative impact on material performance, and achieve the effects of reducing consumption, simplifying the manufacturing process, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Using scrap steel and pig iron as raw materials, through 80t electric arc furnace melting, ladle refining, VD vacuum degassing, and continuous casting process, a continuous casting round billet with a diameter of Φ160 mm is produced. The weight percentage of its chemical composition is: C 0.11%, Si 0.28 %, Mn 1.0%, S0.0011%, P 0.008%, Ti 0.012%, Al 0.025%, Ca 0.002%, N 0.007%, Ni 0.03%, Cu 0.04%, Cr0.05%, the rest is Fe and unavoidable of impurities.

[0057] In the electric arc furnace smelting process, arc heat is used to melt pig iron and scrap steel and raise the temperature of the molten pool. Cluster oxygen lances are used to blow oxygen for decarburization and temperature increase, and 3t of active lime is added for slagging and dephosphorization. When the carbon content in the molten pool is 0.06- 0.09 wt.%, phosphorus content ≤ 0.008wt.%, and the temperature is 1600-1630 ℃ before steel can be tapped. Add 1.5~2.5kg / t aluminum ingot, 8~9 kg / t metal manganese, 1....

Embodiment 2

[0069] Using scrap steel and pig iron as raw materials, through 80t electric arc furnace melting, ladle refining, VD vacuum degassing and continuous casting process, the continuous casting round billet with a diameter of Φ180 mm is produced. The weight percentage of its chemical composition is: C 0.12%, Si 0.23 %, Mn 1.1%, S0.0012%, P 0.007%, Ti 0.015%, Al 0.024%, Ca 0.0018%, N 0.007%, Ni 0.03%, Cu 0.04%, Cr0.05%, the rest is Fe and unavoidable of impurities.

[0070] In the electric arc furnace smelting process, arc heat is used to melt pig iron and scrap steel and raise the temperature of the molten pool. Cluster oxygen lances are used to blow oxygen for decarburization and temperature increase, and 3t of active lime is added for slagging and dephosphorization. When the carbon content in the molten pool is 0.06- 0.09 wt.%, phosphorus content ≤ 0.008 wt.%, and the temperature is 1600-1630 ℃ before steel can be tapped. Add 1.5~2.5kg / t aluminum ingot, 8~9 kg / t metal manganese,...

Embodiment 3

[0082] Using scrap steel and pig iron as raw materials, through 80t electric arc furnace melting, ladle refining, VD vacuum degassing and continuous casting process, the continuous casting round billet with a diameter of Φ210 mm is produced. The weight percentage of its chemical composition is: C 0.13%, Si 0.25 %, Mn 1.2%, S0.0011%, P 0.007%, Ti 0.013%, Al 0.026%, Ca 0.0021%, N 0.007%, Ni 0.03%, Cu 0.04%, Cr0.05%, the rest is Fe and unavoidable of impurities.

[0083] In the electric arc furnace smelting process, arc heat is used to melt pig iron and scrap steel and raise the temperature of the molten pool. Cluster oxygen lances are used to blow oxygen for decarburization and temperature increase, and 3t of active lime is added for slagging and dephosphorization. When the carbon content in the molten pool is 0.06- 0.09 wt.%, phosphorus content ≤ 0.008wt.%, and the temperature is 1600-1630 ℃ before steel can be tapped. Add 1.5~2.5kg / t aluminum ingot, 8~9 kg / t metal manganese, ...

PUM

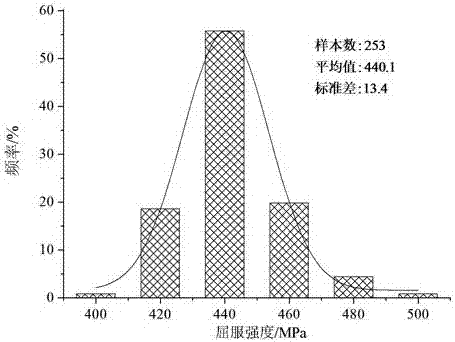

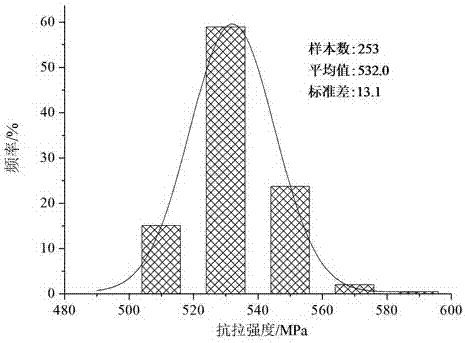

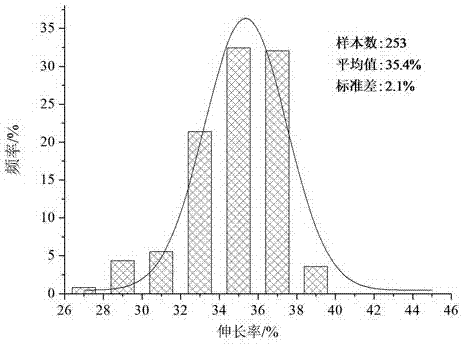

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com