Lithium-ion battery composite membrane and preparation method thereof and lithium-ion battery

A technology of lithium-ion batteries and composite diaphragms, applied in secondary batteries, battery pack components, secondary battery repair/maintenance, etc., can solve problems such as safety accidents, need for improvement, and inability to prevent battery short circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

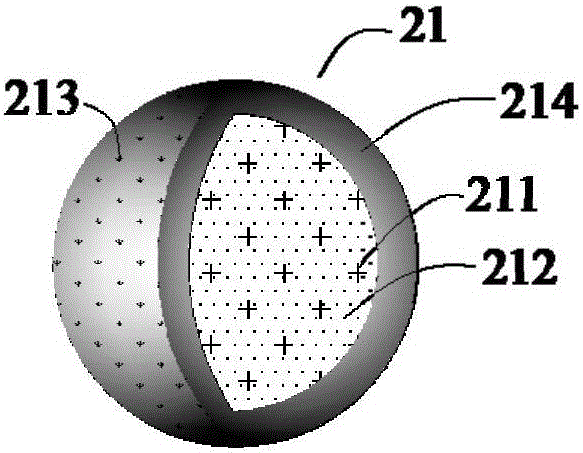

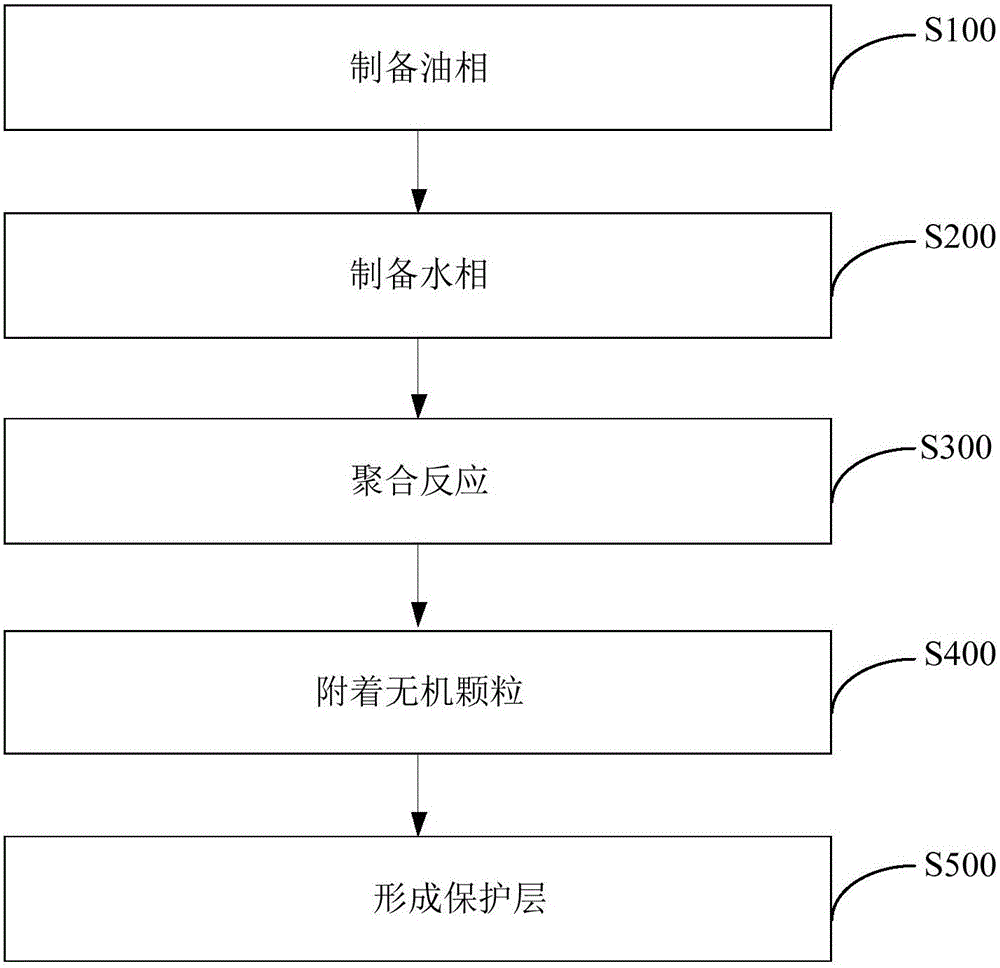

[0058] 10 parts by weight of paraffin wax with a melting point of 52°C, 3 parts by weight of styrene, 1 part by weight of divinylbenzene, 0.5 parts by weight of chlorinated paraffin, and azobisisobutyronitrile were mixed and heated to 70°C to form an oil phase. After mixing water and polymer surfactant, the temperature was raised to 70° C. to form the water phase. Mix the oil phase and the water phase evenly, and carry out high-speed stirring for 10 minutes, and the stirring speed is not lower than 5000 rpm. Afterwards, nitrogen gas was introduced, and the phase-change microcapsules were obtained after polymerization for 8 hours. The phase-change microcapsule powder can be obtained by freeze-drying the emulsion.

[0059] Mix 10 parts by weight of phase-change microcapsule powder with 100 parts by weight of ethanol, 40 parts by weight of secondary water and 20 parts by weight of ammonia water, add 10 parts by weight of tetraethyl orthosilicate under stirring, stir at room temp...

Embodiment 2

[0062] 10 parts by weight of paraffin wax with a melting point of 25°C, 3 parts by weight of styrene, 1 part by weight of divinylbenzene, 0.5 parts by weight of chlorinated paraffin, and azobisisobutyronitrile were mixed and heated to 70°C to form an oil phase. After mixing water and polymer surfactant, the temperature was raised to 70° C. to form the water phase. Mix the oil phase and the water phase evenly, and carry out high-speed stirring for 10 minutes, and the stirring speed is not lower than 5000 rpm. Afterwards, nitrogen gas was introduced, and the phase-change microcapsules were obtained after polymerization for 8 hours. The phase-change microcapsule powder can be obtained by freeze-drying the emulsion.

[0063] Mix 10 parts by weight of phase-change microcapsule powder with 100 parts by weight of ethanol, 40 parts by weight of secondary water and 20 parts by weight of ammonia water, add 10 parts by weight of tetraethyl orthosilicate under stirring, stir at room temp...

Embodiment 3

[0066] 10 parts by weight of paraffin wax with a melting point of 52°C, 4 parts by weight of styrene, 2 parts by weight of divinylbenzene, 0.5 parts by weight of chlorinated paraffin, and azobisisobutyronitrile were mixed and heated to 70°C to form an oil phase. Mix water and polymeric surfactant and raise the temperature to 70°C as a phase. Mix the oil phase and the water phase evenly, and carry out high-speed stirring for 10 minutes, and the stirring speed is not lower than 5000 rpm. Afterwards, nitrogen gas was introduced, and the phase-change microcapsules were obtained after polymerization for 8 hours. The phase-change microcapsule powder can be obtained by freeze-drying the emulsion.

[0067] Mix 10 parts by weight of phase-change microcapsule powder with 100 parts by weight of ethanol, 40 parts by weight of secondary water and 20 parts by weight of ammonia water, add 10 parts by weight of tetraethyl orthosilicate under stirring, stir at room temperature for 8 hours, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com